Abstract

The blue recycling bins that we throw our cardboard and plastics away in have made recycling extremely convenient, but what actually happens to the materials we put in these bins? First, the mixture of materials must be sorted using a combination of manual and automated processes. Relying on the laws of physics, the machines sort the materials based on magnetic properties, physical size, and weight. The separated materials can then be recycled through the process of cleaning, melting, and extrusion. However, since there are a variety of plastic types, whether or not each type of plastic will be recycled depends heavily on current market demands and the profitability of that material.

Introduction

As environmental concerns intensify, confusion pervades the discussion on household recycling. There are various narratives that educate the public about what defines a “recyclable” material. Without a proper understanding of the recycling process, many of us are guilty of placing anything and everything in the blue bins with hopes that it will all be salvaged. This confusion largely emanates from the interconnectedness between recycling trends and market swings. While capabilities to recycle most household products exist, centers will not accept materials unless there is a profitable market creating a demand for the reprocessed goods. Additionally, contamination due to food residue or non-recyclables can render a whole batch of materials unusable. Therefore, it is important for consumers to understand the recycling process as well as current market conditions to properly participate in recycling at the consumer level.

History

Throughout history, recycling trends have shifted alongside the economy. The Great Depression of the 1930s forced a spirit of resourcefulness, encouraging people to create clothing out of flour sacks and construction materials out of tires [1]. During World War II, citizens collected metals and rubbers for scrap drives to help build ships, airplanes, and war equipment [1]. By the 1950s, however, the rising post-war consumerism created a “throw-away” culture that overshadowed these recycling efforts [2]. With the first Earth Day in 1970, growing environmental concerns spurred the emergence of drop-off centers that accepted various materials at a centralized location. By the 1980s, the blue bins that we are familiar with today appeared in households to facilitate recycling at the consumer level.

These blue bins began the trend of single-stream recycling, the system in which plastics, paper, metal, and glass can be collected together and transported to a material recovery facility for sorting. The convenience of this low-effort disposal process coupled with curb-side pickup services encouraged consumer-level participation, increasing the amount of recycled municipal waste from 6 percent in 1960 to 16 percent in 1990 [3]. In the early 2000s, single-stream recycling flourished as China began accepting the world’s recyclables in a profitable trade scenario where household waste became resources for China’s manufacturing. Shipping containers bringing consumer goods to the U.S. were loaded with waste before returning to China, where migrant workers hand-sorted trash from recyclables. By 2016, the U.S. was sending 700,000 tons of plastic waste a year to China, effectively reducing operation and improvement costs of domestic landfills and recycling facilities [4]. However, on January 1, 2018, China stopped accepting these shipments, leaving countries such as the U.S. with too much waste and insufficient infrastructure to reprocess these recyclables [5].

General Sorting Process

With the front-end convenience of single-stream recycling comes the back-end necessity to separate the mingled materials. Once the curbside bins are sent to a material recovery facility (MRF), a series of manual and automated processes separate plastics, metals, papers, and glass. As the materials travel on a conveyor belt, workers remove non-recyclable items such as trash, food-contaminated containers, and hoses [6]. The paper products then travel up an inclined screen while heavier containers drop onto a separate conveyor belt. These containers then pass under overhead magnetic belts that attract steel and tin cans, delivering them to specialized holding containers [7]. After the ferrous metals have been removed, a reverse magnet called an eddy current repels aluminum cans, forcing them into discharge zones [8]. Once the metals are removed, heavy glass falls off the conveyor belt into a pit, while lighter plastic materials continue for manual or optical sorting.

Figure 1: Conveyor belts at a material recovery facility used to sort recyclables [7]

Optical sorting systems use a spectrometer to identify different material types based on the light waves that each material reflects. These machines identify different types of plastic materials, calculate their location on the conveyor belt, and send blasts of air to force the targeted objects into designated separation zones [9]. In addition to plastic types, many of these machines are also equipped to identify and sort glass, wood, paper, and cardboard [9]. After the materials are sorted, they are packed into homogenous bales of 1,000 to 1,500 pounds and sent to specialized recycling facilities designed to process individual material types [7].

Figure 2: Single-stream recycling process

This method of single-stream recycling is relatively inefficient due to the risk of contamination by misplaced food, liquids, or broken glass [6]. Cardboard and paper covered in food residue, grease, or liquids are effectively non-recyclable, so one misplaced container filled with excess liquid can spill onto other items in a bin, forcing everything to be sent to the landfill. Broken glass is also considered a contaminant, since it creates a hazard for workers and typically cannot be removed by automated machinery. The efficiency of this recycling process is also reduced by plastic bags and straws, which clog sorting equipment and require more reliance on manual labor. Finally, while material recovery facilities can sort different types of materials, many do not have the capabilities to separate materials integrated into a single item, such as the thin layer of plastic lining the inside of cardboard coffee cups.

Plastic Recycling

Plastics, or moldable materials made from polymers, can be classified as either thermoplastics or thermoset plastics. Thermoplastics, which are composed of repeating monomers linked with physical bonds, are recyclable since they can be melted and molded into new products [10]. Due to their versatility and moldability, thermoplastics are typically used in plastic containers, bottles, and plastic bags [11]. Thermoset plastics, on the other hand, are composed of cross-linked polymers that form an irreversible chemical bond resistant to heating, and therefore cannot be recycled [10]. Due to their strength, hardness, and thermal stability, thermoset plastics are typically used in automotive parts, electronics, and appliances [11].

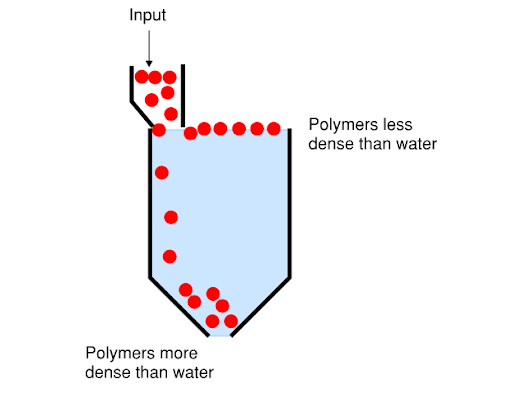

When it comes to household recycling, the disposable plastics we place in bins are largely thermoplastics. After these materials have been sorted at MRFs, the bales are sent to plastic recycling facilities where the materials are washed using steam and chemicals. This cleaned material is then ground into small flakes and contaminants are further removed using the sink-float technique in which high-density materials sink while low-density materials float in a tank of water. For instance, when plastic water bottles are ground into flakes, the plastic flakes of the bottle sink to the bottom, but the label and bottle cap flakes, which are less dense than water, float [12]. The separated and washed flakes are then melted, extruded through screens, and cooled into pellets of uniform size so they can be used to create new products, either alone or mixed with virgin materials.

Figure 3: Sink-float separation technique

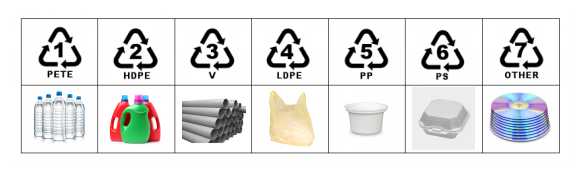

Plastic Types

Household plastics are labeled with numbers ranging from ‘one’ to ‘seven’ to indicate the type of plastic. Each number represents a category of plastics with unique properties and chemical structures, some of which are more suited for recycling in terms of efficiency, profitability, and market demand. Local facilities vary regarding which numbers they will accept.

Figure 3: Recycled plastic pellets [13].

#1: Polyethylene Terephthalate (PET) – Commonly used in beverage bottles, plastic peanut butter jars, and household cleaners, PET is a highly recyclable thermoplastic. A strong, thermostable, and transparent material, PET can be broken down at low temperatures, minimizing degradation and allowing it to be recycled many times [14]. Recycled PET is commonly used in clothing fabric, polyester carpet fibers, athletic shoes, upholstery, and luggage.

#2: High Density Polyethylene (HDPE) – Primarily used in milk jugs, shampoo bottles, cleaning product containers, and detergent bottles, HDPE is another recyclable thermoplastic. The plastic is known for its high tensile strength and chemical resistance and can be recycled at least 10 times without seeing diminished properties [15]. New products created from recycled HDPE include rope, toys, piping, recycling bins, and trash cans.

#3: Polyvinyl Chloride (PVC) – Characterized as a soft and flexible plastic, PVC is a difficult-to-recycle thermoplastic used in tubing, toys, and furniture. Since PVC is produced with additives to manipulate the flexibility and chemical properties of the material, it is difficult to break the vinyl down to recover the original components for recycling [16]. It is also known as the “poison plastic” since production and incineration of PVC release toxic dioxins [16].

#4: Low Density Polyethylene (LDPE) – Mainly used in plastic films, LDPE is a thermoplastic used to make grocery bags and plastic wrappings. This flexible material can cause jams in sorting machinery and therefore is often not recycled. Additionally, these films and bags are difficult to clean and decontaminate, so most are sent to the landfill.

#5: Polypropylene (PP) – Used in yogurt containers and pill bottles, PP is a thermoplastic with a low rate of recycling. Not only does the polymer retain odors easily, but it also can only withstand about four recycling cycles before the hydrogen and carbon bonds become severely weakened due to the high temperature needed to melt the material [17].

#6: Polystyrene (PS) – Used in disposable coffee cups, packing peanuts, and to-go food containers, polystyrene is a lightweight, porous thermoplastic that is difficult to clean. While the material is recyclable, many facilities do not accept it because its large air content reduces its value as a recyclable material. Expanded polystyrene contains 98% air, making it resource-efficient but bulky and expensive to transport [18].

#7: Other – This final category encompasses the plastic types that do not fit into the other classifications. This includes multi-layered resins and plant-based and bio-based plastics. Due to the broad nature of this categorization, it is common for recycling centers to not accept them.

Figure 4: Household plastic types #1-7

While the plastics labeled with these numbers are all thermoplastics that can be recycled, market demands drive whether facilities will accept them at any given point in time. While plastics numbered ‘one’ and ‘two’ are readily recycled, some facilities do not recycle numbers ‘five’ through ‘seven’ since it is cheaper to produce new material instead.

Environmental Impact

When plastics are not recycled due to contamination, disposal, or unprofitable recycling trends, many end up in landfills. With China’s refusal to accept recyclable waste shipments, the rate of plastic disposal has significantly increased. In 2018, Los Angeles county alone discarded over half a million tons of plastic in landfills [19]. When non-biodegradable plastics, including those labeled ‘one’ through ‘six’, are sent to landfills, they can take centuries to decompose [15]. Bacteria cannot break down the durable material, and the lack of exposure to sunlight prevents photodegradation [20]. When they do finally break down, toxic chemicals such as bisphenol A (BPA) and PS oligomer are released, which can disrupt hormone functioning in animals [20]. Biodegradable plastics, such as polylactic acid, which is made from fermented plant starch, are praised as sustainable alternatives that can decompose four times faster than traditional plastics [10]. However, these can only degrade efficiently at specific temperature and humidity levels not present in a typical landfill, meaning that they function comparably to traditional plastics when thrown away.

Alternatively, burning the waste is also used as a disposal process for plastics. In 2018, Los Angeles county sent 20,000 tons of plastic to an incinerator [19]. Since plastics are made from oil and gas, burning this material creates heat that can be harnessed as an energy source. However, burning plastics releases dioxins that can leak into the environment and generates carbon emissions that pollute the air. In Pennsylvania, a city that houses a waste incinerator has reported ovarian cancer rates 64% greater and lung cancer rates 24% greater than the rest of the state, attributed at least in part to the dioxins and volatile organics released from burning plastic [21].

In general, recycling plastic as a replacement for producing virgin materials reduces energy and fossil fuel use [22]. Recycled PET results in a 79% reduction in energy consumption and a 67% reduction in emissions compared to virgin material production [22]. PET and HDPE both result in an 88% reduction in energy consumption and a 71% reduction in emissions [22]. Recycling, both in its ability to prevent plastic from leaching toxins in landfills or incinerators and its ability to reduce virgin material production, provides a more sustainable destination for the disposable products and packaging that dominate our throw-away culture.

Future

Currently, recycling in the U.S. is at a low point. Even with some waste currently being diverted to foreign markets in countries such as Vietnam and Malaysia, China’s refusal to accept recyclable waste has left the U.S. with about 19,000 shipping containers worth of plastic each month [19]. Furthermore, it has exposed the fact that the U.S. is only capable of recycling 9% of its plastics [19]. Even as consumers continue to place recyclables in their blue bins, these materials are largely ending up in landfills and incinerators, since the costs of disposal are less than the costs of recycling without a profitable market.

While this present reality seems grim, it can also serve as a wake-up call. Previously, it was easy to justify our throw-away culture by commending ourselves for placing our plastic packaging in the blue bins. Now, however, knowing that much of this plastic ends up in landfills rather than recycling centers puts pressure on us as consumers to fundamentally change our role in the environment and create sustainable habits. Yes, recycling used products is important for the environment, but it is also important to buy recycled products and minimize the use of disposables. Through our actions at the consumer level, we need to create an imperative for manufacturers to use recycled or biodegradable materials as packaging. The act of placing plastic in a blue bin is a start, but a sustainable future requires a world in which fewer virgin materials are created and more materials are reused. For the short term, though, recycling can benefit from consumers simply being mindful of their recycling practices. Without contaminated materials thrown haphazardly in the bins, the recycling process becomes more efficient and allows for more waste to be salvaged and reprocessed.

Links for further reading:

https://www.thebalancesmb.com/an-overview-of-single-stream-recycling-2877728

https://blog.nationalgeographic.org/2018/04/04/7-things-you-didnt-know-about-plastic-and-recycling/

Multimedia Applications:

https://www.youtube.com/watch?v=yl1auc_MluQ

https://www.youtube.com/watch?v=K2KKmh-CYTg

https://www.youtube.com/watch?v=hdGjiKJsgRk

References

[1] “The Hidden Past of Recycling,” Busch Systems Resource Center, 10-Aug-2017. [Online]. Available: https://www.buschsystems.com/resource-center/page/the-hidden-past-of-recycling. [Accessed: 29-Feb-2020].

[2] N. Seldman, “Brief History of Post WW II US Recycling Movement,” Institute for Local Self-Reliance, 02-Jul-2012. [Online]. Available: https://ilsr.org/history-post-ww-ii-recycling-movement/. [Accessed: 29-Feb-2020].

[3] S. M. Eldred, “When Did Americans Start Recycling?,” History.com, 14-Apr-2020. [Online]. Available: https://www.history.com/news/recycling-history-america. [Accessed: 10-May-2020].

[4] H. Ritchie and M. Roser, “Plastic Pollution,” Our World in Data, 01-Sep-2018. [Online]. Available: https://ourworldindata.org/plastic-pollution#plastic-waste-per-person. [Accessed: 10-May-2020].

[5] J. Reed, D. Blood, L. Faunce, and L. Hook, “Why the world’s recycling system stopped working,” Financial Times, 25-Oct-2018. [Online]. Available: https://www.ft.com/content/360e2524-d71a-11e8-a854-33d6f82e62f8. [Accessed: 29-Feb-2020].

[6] R. LeBlanc, “Single-Stream Recycling Offers Benefits, Creates Challenges,” The Balance Small Business, 27-Nov-2019. [Online]. Available: https://www.thebalancesmb.com/an-overview-of-single-stream-recycling-2877728. [Accessed: 30-Jan-2020].

[7] “What Is a Materials Recovery Facility (MRF)?,” Rubicon Global: Waste, Recycling, and Smart City Technology Company, 05-Feb-2020. [Online]. Available: https://www.rubiconglobal.com/blog/materials-recovery-facility/. [Accessed: 29-Feb-2020].

[8] “Eddy current separators,” Goudsmit Magnetics. [Online]. Available: https://www.goudsmitmagnets.com/industrial-magnetic-systems/recycling-sorting/eddy-current-separators. [Accessed: 30-Jan-2020].

[9] W. F. | S. 09, “A Look at Optical Sorting,” Waste360, 29-Aug-2016. [Online]. Available: https://www.waste360.com/commentary/look-optical-sorting. [Accessed: 29-Feb-2020].

[10] L. Sedaghat, “7 Things You Didn’t Know About Plastic (and Recycling),” National Geographic Society Newsroom, 13-Apr-2018. [Online]. Available: https://blog.nationalgeographic.org/2018/04/04/7-things-you-didnt-know-about-plastic-and-recycling/. [Accessed: 30-Jan-2020].

[11] “Thermoset vs. Thermoplastics – A Comparison of Materials, Advantages and Disadvantages,” Thermoset vs. Thermoplastics – A Comparison of Materials, Advantages and Disadvantages. [Online]. Available: https://www.thomasnet.com/articles/plastics-rubber/thermoset-vs-thermoplastics/. [Accessed: 10-May-2020].

[12] “Sink-float tank for separation of different types of plastics,” B B Anlagenbau. [Online]. Available: https://www.bub-anlagenbau.de/products/separation/sink-float-tank/. [Accessed: 10-May-2020].

[13] A. Karidis, “Startup Nyltec Polymers Makes PET Pellets to Replace Nylon 6,” Waste360, 19-Sep-2019. [Online]. Available: https://www.waste360.com/plastics/startup-nyltec-polymers-makes-pet-pellets-replace-nylon-6. [Accessed: 29-Feb-2020].

[14] G. P. ThomasJul, “Recycling of Polyethylene Terephthalate (PET or PETE),” AZoCleantech.com, 22-May-2019. [Online]. Available: https://www.azocleantech.com/article.aspx?ArticleID=254. [Accessed: 30-Jan-2020].

[15] G. P. ThomasJul, “Recycling of High-Density Polyethylene (HDPE or PEHD),” AZoCleantech.com, 17-Apr-2019. [Online]. Available: https://www.azocleantech.com/article.aspx?ArticleID=255. [Accessed: 30-Jan-2020].

[16] “How to Recycle PVC (Plastic #3),” Ecolife. [Online]. Available: http://www.ecolife.com/recycling/plastic/how-to-recycle-pvc-plastic-3.html. [Accessed: 30-Jan-2020].

[17] G. P. ThomasJun, “Recycling of Polypropylene (PP),” AZoCleantech.com, 16-Aug-2019. [Online]. Available: https://www.azocleantech.com/article.aspx?ArticleID=240. [Accessed: 30-Jan-2020].

[18] “Top 5 Things You Need to Know About Polystyrene,” DSSmith.com Engineered Foam Products. [Online]. Available: https://www.engineeredfoamproducts.com/insights/top-5-things-you-need-to-know-about-polystyrene/. [Accessed: 10-May-2020].

[19] E. McCormick, C. Simmonds, J. Glenza, and K. Gammon, “Americans’ plastic recycling is dumped in landfills, investigation shows,” The Guardian, 21-Jun-2019. [Online]. Available: https://www.theguardian.com/us-news/2019/jun/21/us-plastic-recycling-landfills. [Accessed: 10-May-2020].

[20] W. Harris, “How long does it take for plastics to biodegrade?” HowStuffWorks Science, 27-Jan-2020. [Online]. Available: https://science.howstuffworks.com/science-vs-myth/everyday-myths/how-long-does-it-take-for-plastics-to-biodegrade.htmwhat. [Accessed: 10-May-2020].

[21] O. Milman, “Since China’s Ban, Recycling in the US Has Gone Up in Flames,” Wired. [Online]. Available: https://www.wired.com/story/since-chinas-ban-recycling-in-the-us-has-gone-up-in-flames/. [Accessed: 10-May-2020].

[22] K. Pyzyk, “APR: Recycled plastics reduce energy consumption, GHG emissions,” Waste Dive, 29-Jan-2019. [Online]. Available: https://www.wastedive.com/news/apr-recycled-plastics-reduce-energy-consumption-ghg-emissions/547027/. [Accessed: 10-May-2020].