Abstract

Waste from construction and demolition debris experienced a 420 percent spike between 2005 and 2017 [1]. To minimize the built environment’s negative impacts, architects and engineers can manipulate the rules of conventional construction to replace ordinary materials with recycled ones. Through the lens of conventional masonry construction, industry professionals can replace bricks with recycled plastic bags, tires, and hay bales, to create aesthetically pleasing architecture that will minimize the environmental impact buildings have. This article will explore innovative technology using both unorthodox materials that have yet to be implemented into the field as well as recycled materials already being used in existing buildings to make aesthetic and environmentally friendly architecture. Through the exploration of two projects from the architecture firm Rural Studio and one engineering project conducted by a university student, it is clear that these unorthodox and recycled materials are ready to be introduced into the architecture and engineering worlds.

Introduction

A beautiful piece of architecture is a portal to a world of intricate systems of materials. When you first interact with a building, your mind does not think about the environmental impact it has. Take, for instance, one of the most recognized buildings in the world, the Empire State Building. When we first interact with this building, we do not realize it consumed the same amount of energy as 40,000 single-family homes daily in 2013 [1]. Instead, we take in the beautiful facades and architectural details. The responsibilities of architects and engineers have grown to include finding innovative ways to lessen the negative impact their buildings cause. We must shift our focus to using unorthodox materials—materials we do not typically associate with the built environment—to lessen its environmental impact, while still maintaining the aesthetics of architecture.

Impacts of the Built Environment

Common construction and demolition materials in our landfills include concrete, wood, metal, brick, glass, plastic, and asphalt [2]. These materials create an abundance of waste, accounting for twice the amount of everyday trash or municipal solid waste in the United States [2]. According to the United States Environmental Protection Agency, in 2017 alone, approximately 569 million tons of construction and demolition debris were produced [2].

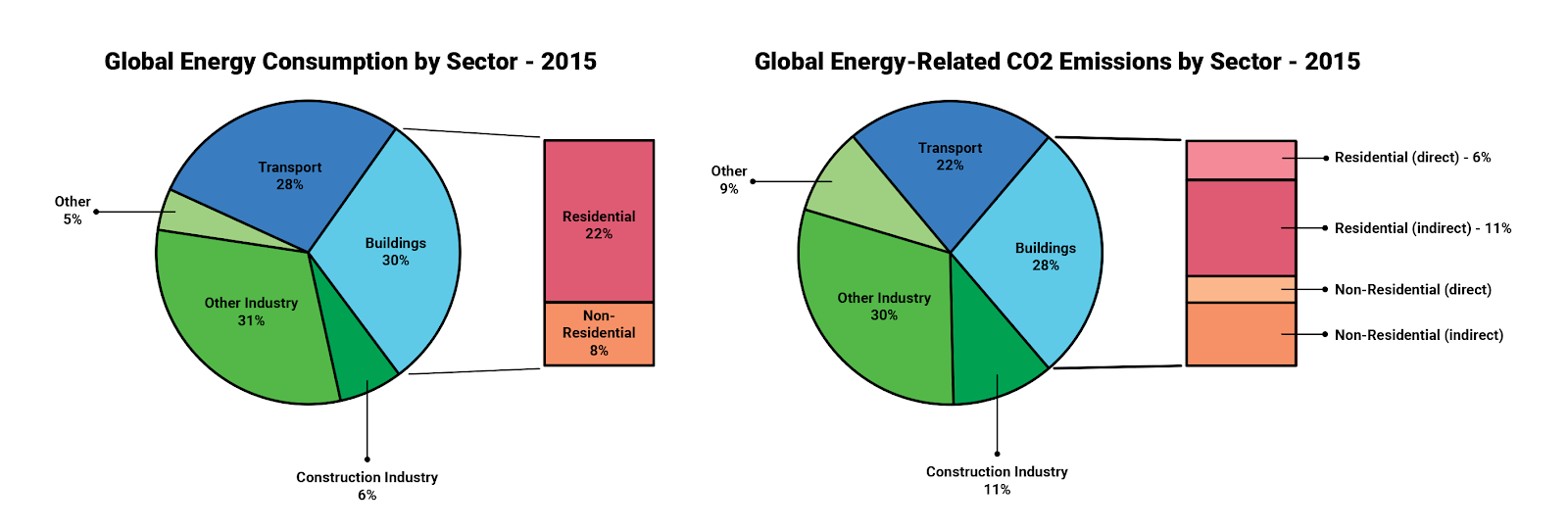

Once the building is fully constructed, it emits carbon dioxide that further damages our environment. The built environment produces approximately 40 percent of the United States’ carbon dioxide emissions [3]. These emissions are calculated using the operational carbon emissions and the embodied carbon of a building. Operational carbon emissions are generated from the daily energy usage of a building and the embodied carbon is generated in the construction and manufacturing process [4]. Separately, building operations are responsible for 28 percent of emissions annually and embodied carbon is responsible for 11 percent of emissions annually [4]. Furthermore, 36 percent of our global energy usage comes from the construction process and energy consumption of buildings [4]. According to the Global Alliance for Buildings and Construction, in 2015, buildings accounted for 30 percent of global energy consumption and 28 percent of carbon emissions, as shown in Figure 1 [5].

Figure 1. Global Energy Consumption and CO2 Emissions by Sector. Adapted from [5]

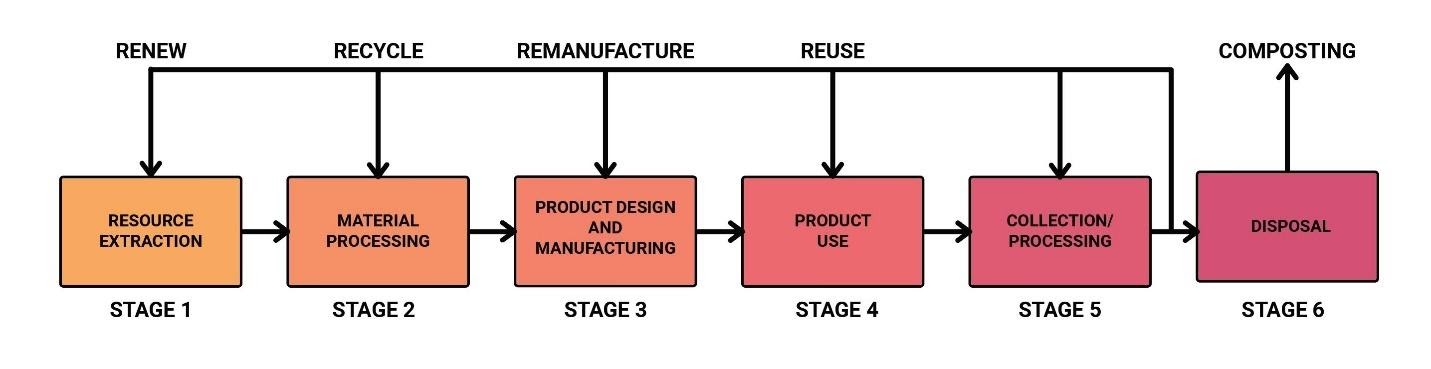

By breaking down the life cycle of a material, we can better understand how we can implement change. Between the roof, floor, wall, and foundation systems, a single building typically contains over 60 basic materials [6]. Each of these materials goes through a standard life cycle that consists of six stages: resource extraction, material processing, product design and manufacturing, product use, collection and processing, and disposal [7]. As shown in Figure 2, each stage of a material’s life cycle opens up opportunities for us to adapt the material in a specific way.

Figure 2. Life cycle of a Material. Adapted from [6]

To further explore each stage of a material’s life cycle, we will look to wood as an example. In the first stage of wood’s life cycle, a tree is cut down and the natural resource is extracted from the Earth. In stage 2, wood is cut into specific dimensions and treated, as needed for the construction process. During product design and manufacturing, or stage 3, the cut lumber is transported to the job site and used in the construction of a building. Stage 4 occurs when the building, which was constructed using the wood, is occupied and maintained. When this existing building is demolished, it undergoes stage 5 of its life cycle. Lastly, in stage 6, the demolished wood and other building materials are transported and dumped at a disposal site.

Throughout each of these stages, the material offers unique opportunities to lessen the overall environmental impact of a building, including reusing, remanufacturing, recycling, renewing, or composting it. These activities are beneficial to our environment and our economy. According to the US Environmental Protection Agency, recycling and reuse activities were responsible for 757,000 jobs, $36.6 billion in wages, and $6.7 billion in tax revenues in 2007 [8]. For every 1000 tons of recycled materials, there are 1.57 jobs, $76,030 in wages, and $14,101 in tax revenues that are created [8].

Conventions of Masonry Construction

To understand how unorthodox materials can be used in buildings, we must delve into the basic conventions of masonry construction. By starting with a traditional construction technique, we can exploit its fundamentals to produce spaces that use unorthodox materials to their fullest extent.

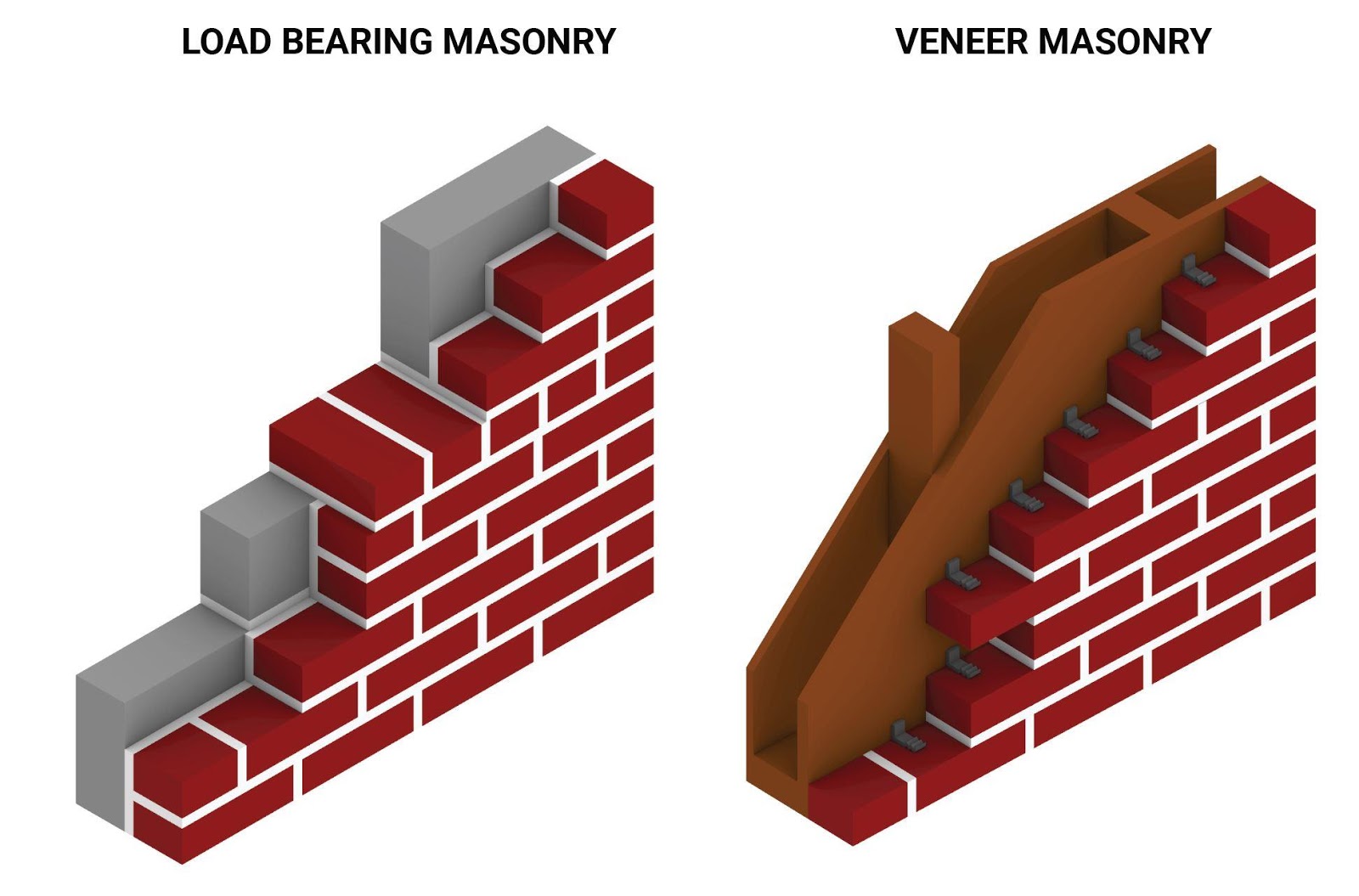

Masonry construction is one of the oldest building techniques still used today. Dating back to prehistoric times, masonry construction consists of the stacking and bonding of individual units to create a cohesive structural system. The simplicity of this modular stacking system allows for an endless selection of techniques, materials, patterns, and stacking methods. Through this form of construction, a single element can serve multiple functions, including thermal, sound, fire, and weather protection [9]. While the individual units are typically bricks, several unconventional materials also meet the modular requirement of masonry construction. As illustrated in Figure 3, there are two primary methods for creating a masonry wall: load-bearing masonry and veneer masonry [10].

Figure 3. Methods of Constructing a Masonry Wall. Adapted from [10].

Load-bearing masonry works through the individual stacking of units without a need for a secondary support system. Through the vertical compressive strength provided by the weight of each unit, load-bearing masonry can self-support the floors and roofs of a building [10]. The masonry units are placed a layer at a time and are held together by an adhesive agent. The adhesive agent commonly used today in masonry construction is mortar [10]. Typically, 20 percent of the surface area of a masonry wall consists of mortar [10].

Veneer masonry is more commonplace in today’s buildings. Unlike the load-bearing system, which can support the floors and roofs by itself, a veneer system requires secondary support or a structural skeleton to hold up the weight of a building [9]. In traditional residential buildings, the structural skeleton typically consists of wood or metal stud walls, as shown in figure 3 [10]. Through this system, the wall produced has a thinness to it that typically cannot be created in a load-bearing system. This form of masonry construction is also relatively easy to install, can be completed in a shorter amount of time, and reduces the weight of the overall building.

The fundamentals of masonry construction provide the basis for how we can use unorthodox materials to lessen the environmental impact of a building, while maintaining its aesthetic qualities.

Recycled Materials

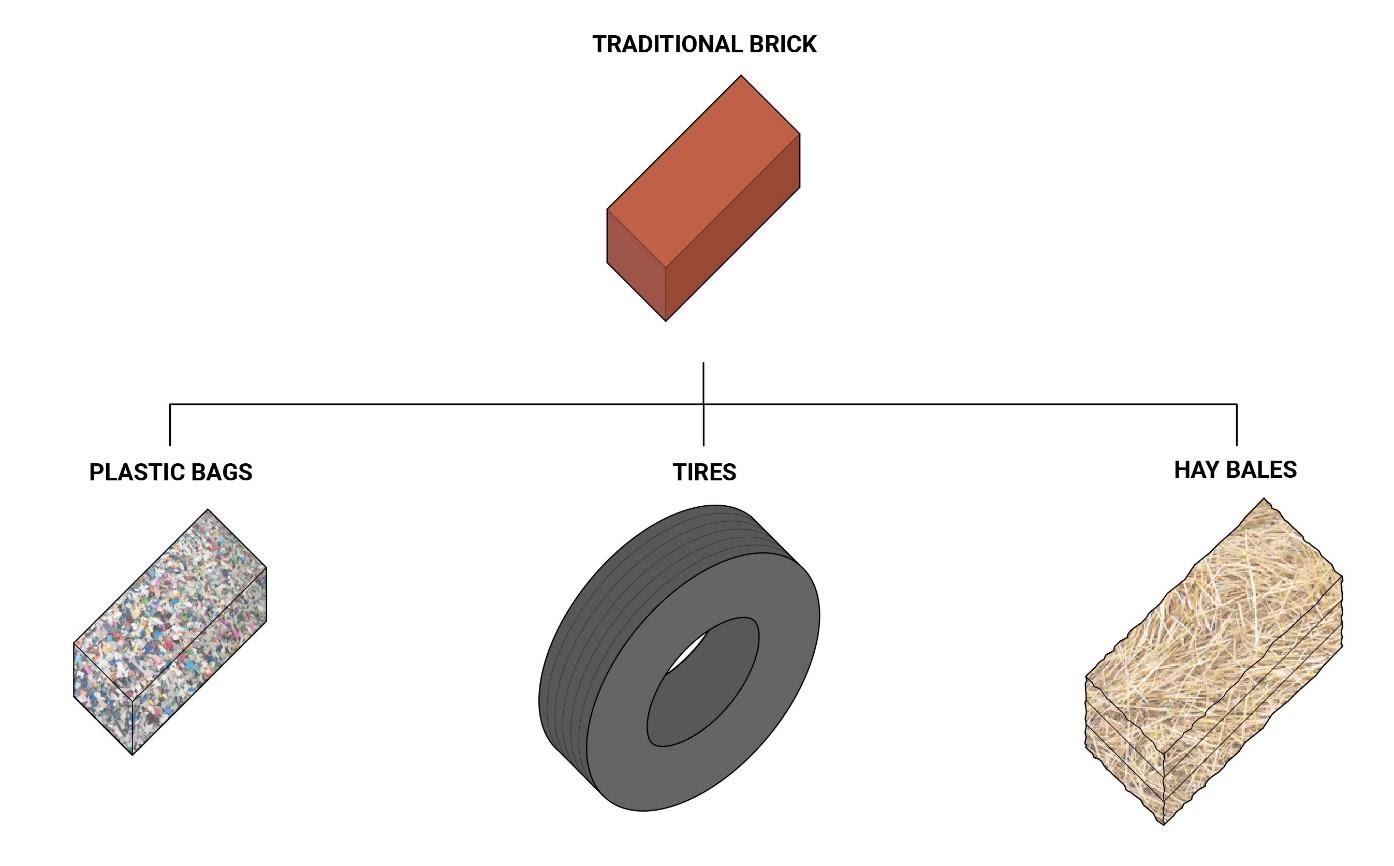

By using unorthodox materials from our daily lives,we can significantly reduce the environmental footprint of a building. While ideas of recycling are already integrated into our communities through multiple measures, such as placing recycling bins in public spaces, we must do more to outweigh the negative impacts our buildings have on the environment. Through the continued integration of unorthodox materials and the invention of new methods to reuse materials, we can further its impact. Architecture can still hold its aesthetic qualities but can do so with materials that do not impact the environment as negatively as today’s materials. These techniques are already being utilized in architecture firms today, such as the Rural Studio, which aims to implement the conventions of construction to use less common materials in their buildings [11]. As shown in figure 4, the conventional brick is already being replaced with unorthodox and recycled materials.

Figure 4. Unorthodox materials. Original Visual

Plastic Bags

According to the Environmental Protection Agency, in 2017, 4.14 million tons of waste from plastic bags, sacks, and wraps were generated [12]. Out of this waste, only 9 percent was recycled [12]. A young engineering student saw this opportunity and, with the help of colleagues, was able to produce an interlocking brick from plastic waste. Named the PlastiQube, this plastic brick uses 0.6 kg of plastic waste from discarded plastic water bottles, plastic bags, and plastic containers [13]. As shown in figure 5, this product is made from shredding this waste and creating a brick from those shavings.

Figure 5. Plastiqube. Adapted from [13].

The original plastic waste goes through a series of five manufacturing stages, ultimately ending in the PlastiQube [13]. The first stage consists of gathering the plastic waste from junkyards and landfills. In the second stage, this waste is shredded into small, compactable pieces. Then, it is superheated and steam treated to rid it of any toxins. This melted down material is then compacted and lastly, formed into the PlastiQube. This process eliminates the need for kilns, which are used in traditional masonry manufacturing, thus reducing the product’s overall energy usage by 70 percent [13].

Eco-friendly PlastiQube bricks are also lighter and more cost effective than traditional bricks [13]. These plastic bricks have an interlocking effect, which eliminates the need for an adhesive agent between the units. Due to this interlocking system, the plastic bricks can be used in both a load-bearing and veneer system. Furthermore, PlastiQube bricks are good heat and sound insulators, which can help reduce energy usage once a building is constructed [13]. This innovative technology has already been recognized from multiple foundations, including the Singapore International Foundation and India’s Department of Science and Technology.

Tires & Hay Bales

While PlastiQubes have yet to be commercially used, Rural Studio is an architecture firm that currently incorporates unorthodox materials in their architecture. The studio’s social agenda aims to add an extra layer of beauty to their work through these materials, without diminishing their buildings’ spatial qualities. Recognized for being a firm that addresses a variety of social issues, including poverty, homelessness, and environmental issues, Rural Studio believes architects should take on an activist role in their work. As described by their founder, Samuel Mockbee, Rural Studio emphasizes that everyone deserves good architecture no-matter their socio-economic status [11]. Based in a rural and impoverished county of Alabama, this studio aims to produce low-cost spaces that are both performative and functional. In two of its projects, Rural Studio used tires and hay bales, along with their understanding of masonry construction, to create low-cost architecture that is environmentally friendly.

In their first project, the Rural Studio used hay bales to create the walls of a single-family home. Built for two adults and their grandchildren, this house contains a living and kitchen area, bathroom, bedroom, sleeping alcove, and an exterior porch. As shown in figure 6, the 24-inch thick walls consist of stacked hay bales that are stuccoed over with concrete [14].

Figure 6. Bryant Haybale House. Adapted from https://www.world-architects.com/en/rural-studio-newbern/project/bryant-haybale-house

Figure 6. Bryant Haybale House. Adapted from https://www.world-architects.com/en/rural-studio-newbern/project/bryant-haybale-house

These inexpensive and unorthodox hay bales act as a heat and sound insulator. Due to the weight and thickness of the hay bales, the walls follow the conventions of a load-bearing masonry wall. The thick walls create a sense of solidity, as the building does not feel light or insignificant due to its mass and weight.

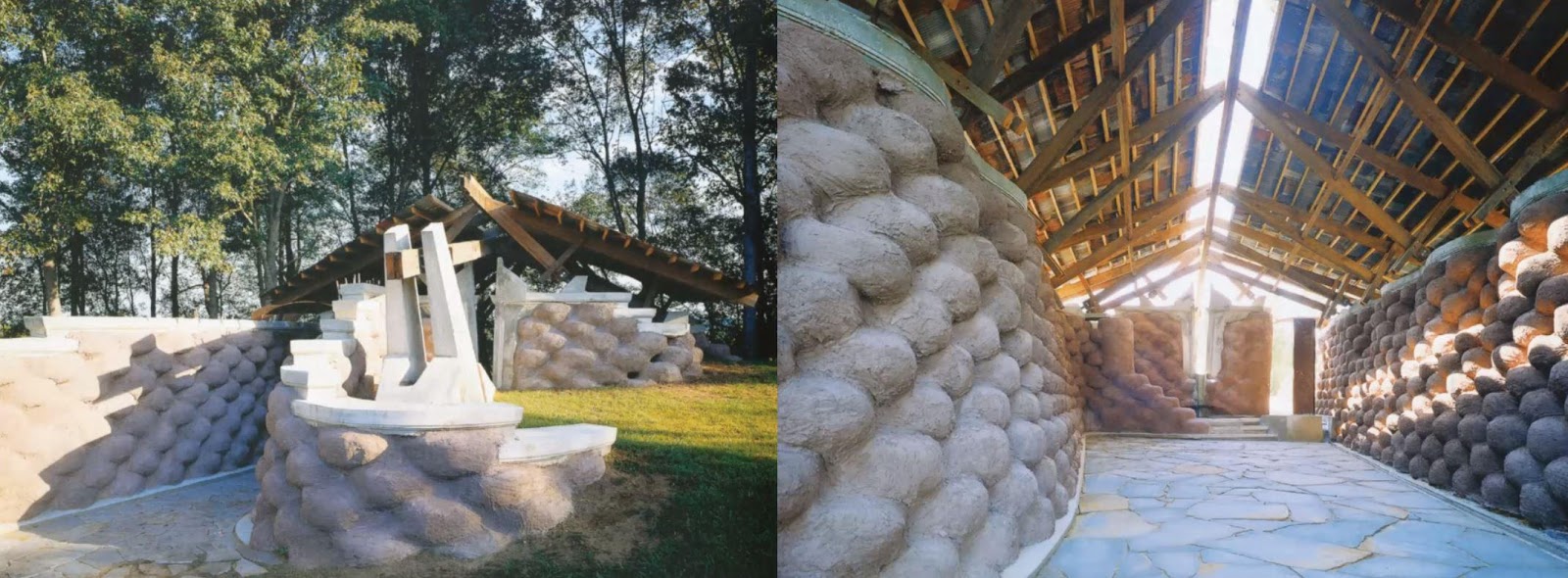

In another project, the Rural Studio used old tires recovered from a landfill to create the chapel walls. The walls are built using 900 stacked tires that are filled with dirt and supported with steel rebar [15]. As shown in figure 7, the stacked tires make up the exterior retaining wall that supports the wood and metal roof.

Figure 7. Yancy Chapel. Adapted from https://www.chilearq.com/gallery/architecture/806/Yancey-Tire-Chapel/

The round shape of the tires produces a unique pattern of differing depths along the walls. The stacking and size of the tires follow the convention of a load-bearing masonry wall. The roof is also environmentally friendly, as it is made of reused wood from an old chapel and rusted metal panels [15]. The found quality of these materials creates the aesthetic of the architectural expression in this building. With all the social goals tied to these buildings, there is still a concern for the beauty of the architecture. The chosen materials do not diminish the quality of the building, but rather create a place with unique and beautiful qualities.

Conclusion

The nature of the current construction process leads to an exaggerated amount of environmental waste and carbon emissions. With a change to unorthodox and recycled materials, we can alter the destructive course that we are headed in. We are not eliminating the experiential qualities of architecture by trading off the materials for cheaper and recycled options, but rather elevating the buildings to a higher social calling. The current impacts that buildings have on the environment allow for an opportunity of invention to fulfill our ethical obligations that far exceed the design of a building. It is time to help reduce the amount of waste and emissions from buildings by innovating unorthodox materials to create aesthetically pleasing architecture.

References

[1] D. Schneider, “How The Empire State Building is Redefining Sustainability and Supporting the Economy in New York City,” 8-May-2013. [Online]. Available: https://blog.nationalgeographic.org/2013/05/08/how-the-empire-state-building-is-redefining-sustainability-and-supporting-the-economy-in-new-york-city/#:~:text=In%20one%20day,%20the%20Empire,25,000%20cars%20from%20the%20road. [Accessed: 03-August-2020]

[2] “Sustainable Management of Construction and Demolition Materials,” EPA, 20-Mar-2020. [Online]. Available at https://www.epa.gov/smm/sustainable-management-construction-and-demolition-materials. [Accessed: 03-Jun-2020].

[3] Environmental and Energy Study Institute and Eesi, “Buildings & Built Infrastructure,” EESI. [Online]. Available: https://www.eesi.org/topics/built-infrastructure/description. [Accessed: 03-Jun-2020].

[4] D. Budds, “How do buildings contribute to climate change?,” Curbed, 19-Sep-2019. [Online]. Available: https://www.curbed.com/2019/9/19/20874234/buildings-carbon-emissions-climate-change. [Accessed: 03-Jun-2020].

[5] T. Abergel, B. Dean, and J. Dulac, “Global Status Report 2017,” UN Environment and International Energy Agency.

[6] A. Haapio and P. Viitaniemi, “Environmental effect of structural solutions and building materials to a building,” Environmental Impact Assessment Review, vol. 28, no. 8, pp. 587–600, 2008.

[7] “Sustainable Materials Management: The Road Ahead,” EPA, 18-Aug-2016. [Online]. Available: https://www.epa.gov/smm/sustainable-materials-management-road-ahead. [Accessed: 03-Jun-2020].

[8] “Recycling Economic Information (REI) Report,” EPA, 31-Jan-2020. [Online]. Available: https://www.epa.gov/smm/recycling-economic-information-rei-report. [Accessed: 03-Jun-2020].

[9] E. A. Hendry, “Masonry walls: materials and construction,” Construction and Building Materials, vol. 15, no. 8, pp. 323–330, 2001.

[10] F. D. K. Ching, Building construction illustrated. Hoboken, NJ: John Wiley & Sons, Inc., 2014.

[11] “About,” Rural Studio, 13-Aug-2019. [Online]. Available: http://ruralstudio.org/about/. [Accessed: 03-Jun-2020].

[12] “Frequent Questions regarding EPA’s Facts and Figures about Materials, Waste and Recycling,” EPA, 07-Nov-2019. [Online]. Available: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/frequent-questions-regarding-epas-facts-and. [Accessed: 03-Jun-2020].

[13] “Construction Bricks: Qube: Interlocking Plastic Bricks: India,” Qube. [Online]. Available: https://www.plastiqube.com/. [Accessed: 03-Jun-2020].

[14] “Bryant Haybale House,” Rural Studio, 14-Jun-2019. [Online]. Available: http://ruralstudio.org/project/bryant-haybale-house/. [Accessed: 03-Jun-2020].

[15] “Yancy Tire Chapel,” Rural Studio, 14-Jun-2019. [Online]. Available: http://ruralstudio.org/project/yancy-tire-chapel/. [Accessed: 03-Jun-2020].