Concrete, that traditionally solid, substantial building material, is getting a makeover. Engineers have now developed concrete mixtures that are capable of transmitting light. By switching the ingredients of traditional concrete with transparent ones, or embedding fiber optics, translucent concrete has become a reality. As with any new material, it is expensive and still has some issues to be resolved. However, this innovative new material, while still partially in the development stages, is beginning to be used in a variety of applications in architecture, and promises vast opportunities in the future.

The Paradox of Translucent Concrete

When you think of concrete, most likely, your mind conjures up images of something solid, heavy, and monolithic. But what if concrete could be translucent, transmitting light into spaces, making them seem light and airy? Engineers today are challenging concrete to shed its opaque reputation to become both window and wall, simultaneously glowing, ethereal, and structural (see Fig. 1). Concrete has been called an “indispensable medium,” the “quintessential material” for architects and engineers, due to the vast “sculptural and expressive possibilities” that it can achieve [5]. Now engineers are expanding those possibilities by modifying the basic ingredients of concrete to create translucent concrete. They are addressing the challenges and problems that occur in every new material, and some companies have started production. In the future, as translucent concrete becomes easier to manufacture and more available, engineers and architects will be able to utilize this amazing material in everything from furniture to entire buildings.

What Makes Concrete Concrete

Concrete has been used since Roman times, but its basic components have remained the same. Three ingredients make up the dry mix: coarse aggregate, consisting of larger pieces of material like stones or gravel; fine aggregate, made up of smaller particles such as sand; and cement, a very fine powder material that binds the mix together when water is added [1]. Modern concrete is most often reinforced with steel, a practice that was developed in the 1850s [2]. The simple formula for concrete, however, lends itself to endless modifications. By simply adjusting the ratio of ingredients, engineers can change the strength and texture of the material [3]. Bigger aggregates lead to rougher concrete and vice versa. Other ingredients, known as admixtures, can be added to alter the concrete’s drying time, workability, color, and consistency [3]. By switching ingredients and adding new ones, engineers have been able to create a multitude of interesting new products, one of which is translucent concrete.

How Translucent Concrete Is Made

Engineers have come up with several potential types of mixtures for translucent concrete. One approach is to exchange the traditional ingredients with transparent or translucent alternatives. Pieces of plastic or glass can be used as aggregates, and the binding agent can be switched with a type of transparent glue [1]. Will Wittig at the University of Detroit Mercy in Michigan combined white silica sand and white Portland cement, and by “varying the ratios”, developed a mix that could be cast much thinner than traditional concrete [3]. His thin translucent concrete blocks were reinforced with “short strands of fiberglass” and were able to transmit a glow of light [3]. A company in Italy has also created their own secret recipe, using a combination of transparent resins as the binding agent [6]. Aggregates can be replaced with transparent alternatives, and the bonding material itself may be able to transmit light by incorporating clear resins in the mix.

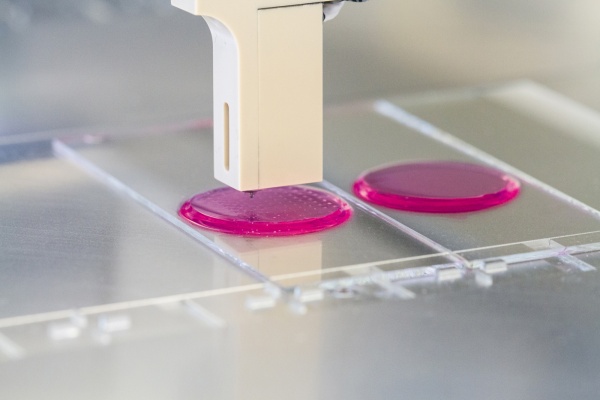

Another approach is the “combination of optical fibers and fine concrete”; this formula, explored by the Hungarian Architect Aron Losoncze, uses very fine aggregate to encase optical fibers that allow light to transmit from one side of a block to the other [7]. The process is slow and done by hand in a long, narrow mold; concrete and optical fibers are layered over each other creating a long beam that is cut into blocks [3]. The blocks are able to retain their strength and bond because “the proportion of the fibers is very small (4%) compared to the total volume of the blocks” [7]. They are not reinforced in the traditional sense, since the “optical glass fibres form a matrix” which creates an internal structure of reinforcement [7]. This method of producing translucent concrete has been more fully explored and is more common.

Potential Problems

Concrete mixtures must be just right in order to maintain structural strength. The same is true of translucent concrete. Some experimental translucent concrete mixes have failed to produce structural consistency. In Wittig’s case “lab tests showed that his panels were too fragile to withstand wind and rain” [3]. New construction products must be extensively tested for strength. Traditional unreinforced concrete has a compressive strength of 1000-4000 psi, and a tensile strength of 0 psi; it is reinforced to gain tensile strength [2]. Losoncze’s optical fiber concrete blocks claim a higher compressive strength of 7252 psi and a surprising tensile strength of 1015 psi even without steel reinforcing. His tests show that “glass fibers do not have a negative effect on the well-known high compressive strength value of concrete” [7]. Fiber reinforcing can make translucent concrete even stronger than traditionally reinforced concrete. Engineers can also use chemical additives to significantly increase the strength of translucent concrete [4]. It is possible to create load-bearing structures out of translucent concrete; however it would also be very expensive. It could be about five times as much to build using translucent concrete as opposed to the traditional type [1]. This is due to the rarity of the product and its experimental nature. However, as engineers continue to experiment, the cost of production will decrease, along with with an increase in demand and more widespread usage [4].

Current Production and Uses

Translucent concrete is not currently widely produced. There are only a select few companies, and the process is somewhat low-tech and slow. It can only be produced as pre-cast or prefabricated blocks and panels; it cannot be poured on site like traditional concrete [1, 7]. The blocks come in a range of sizes, the maximum for glass fiber being 1200 x 400 mm (47.2 x 15.7 inches), and the thickness can range from 25-500mm (1-20 inches) [7]. This allows translucent concrete to be used for a variety of purposes, from a thin veneer to a structural system. According to one German company, it can be used “for ventilated facade systems as well as for interior cladding” [8]. So far translucent concrete has been used to make light installations, signs, and fixed-in-place furniture such as benches, desks, and counters. In its early days, it was used mostly in art installations (see Figure 2) and material demonstrations such as the Liquid Stone exhibit at the National Building Museum [5], and a sidewalk in Stockholm that looked “like an ordinary sidewalk by day but [was] illuminated at night by lights under it” [4]. It is presently used mostly in interiors as decoration, but is making its foray into exterior structural walls.

The Italian Pavilion at the Shanghai World Expo 2010 marked the first major application of translucent concrete in a building [6]. The translucent blocks of concrete were interspersed with opaque blocks to create a seamless façade that allows diffused light in at certain areas, and emanates a glow at night [6]. Surrounding the windows in the center of the figure are concrete blocks some of which are translucent and allow natural light into the building. Recently the Italian Ambassador revealed that translucent concrete is to be used in several buildings at the new Italian Embassy in Bangkok [6]. This would be the second major building use of translucent concrete, as this material is becomes more well known and further developed many more are sure to follow.

A Translucent Future

Although translucent concrete has been used primarily as an interior decoration, its creators have “visions of cities that glow from within, and buildings whose windows need not be flat, rectangular panes, but can be arbitrary regions of transparency within flowing, curving walls” [1]. It “can at the same time be building material and light source, can separate and connect, can be wall or floor, ambient lighting or eye-catcher” [8]. Translucent concrete is also a great insulating material that protects against outdoor extreme temperatures while also letting in daylight [3]. This makes it an excellent compromise for buildings in harsh climates, where it can shut out heat or cold without shutting the building off from daylight. It can be used to illuminate underground buildings and structures, such as subway stations. Translucent concrete could provide safety applications in the future such as speed bumps that could be lit “from below to make them more visible at night”, or to light indoor fire escapes in case of a power failure [4]. It even has the potential to be sustainable; the aggregate can be replaced with crushed recycled glass [3]. It could be used almost anywhere glass or traditional concrete are used. Translucent concrete combines the fluid potential of concrete with glass’ ability to admit light, and it also retains privacy and can be used as structural support. The possibilities for translucent concrete are innumerable; the more it is used, the more new uses will be discovered. In the next few years, as engineers further explore this exciting new material, it is sure to be employed in a variety of interesting ways that will change the opacity of architecture as we know it.