If your phone is anything like most phones these days, it probably has four buttons, and I could probably name them all, regardless of model or manufacture. Volume up, volume down, silent mode, and lock. Four buttons is not a lot to work with, yet your phone is capable of a lot more than four things. Yes, computers have gotten more powerful, but even the most powerful computer isn’t very useful unless a person interacts with it. Screens were how our phones communicated to us, and buttons were how we communicated back. There used to be a trade off between more screens and more buttons, and each phone had to make a trade off between the two. But ever since Steve Jobs showed off the first iPhone, touch screens have exploded in popularity and are everywhere nowadays. This ubiquitous piece of technology is both deceptively simple and surprisingly complex.

The actual screen of a touch screen functions just like any other screen. Just like a regular TV or computer monitor, it consists of an array of pixels which change color to display an image. There is nothing special about the screen part of a touch screen. The touch sensing technology is just something else added on top. In fact, this is how the trackpad of a laptop works. It’s just the touch half, with no display.

Resistive Touch Screens

There are two main types of touch screens: resistive and capacitive. The former type is the most common, not because they’re the ones used in our smartphones, but because they’re the ones used in everything else. Imagine that you’re at an ATM or get to the end of the checkout line at a grocery store, and have to tap or scribble something onto a dim screen. You have to actually press with noticeable force to get it to register. As you push with your finger or stylus, the screen feels tacky and almost rubbery, there’s this friction to it, and you can almost feel it deforming slightly as you apply pressure. Your senses aren’t deceiving you, the screen actually is bending, or at least, some of it is.

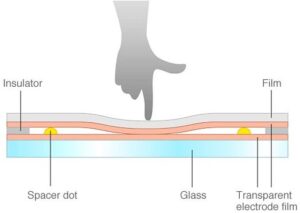

These devices use resistive touch screens, which consist of two layers of tiny wires running across the display. The only thing stopping these two thin layers of electrically conducting material from touching are tiny spacers made of a non-conducting material, called spacer dots, sandwiched between them. When you press on the screen and apply enough pressure, it pushes the two conductive layers into contact with one another, allowing an electric current to pass through from one layer to another at a specific location, completing an electric circuit. The outer layer has to deform slightly, which is why it looks as though the screen flexes very slightly when you use it [1].

Figure 2: Cross section of resistive touch screen deforming to touch [1]

When this circuit is completed, the voltage of the electric signal is measured, and by comparing it to the known input voltage, the computer can calculate how much electrical resistance was encountered by the signal.

The wires used in the touch screen have a known electrical resistance per unit length. Once the total resistance is calculated, the length of wire the signal had to travel through can also be determined. In other words, the strength of the electrical current is dependent on where the screen was touched to send that current to the computer, and vice versa. Different electrical signals correspond to different locations where the screen was touched. This means that, in practice, a resistive touch screen is a thin sheet of tiny buttons draped across a regular display screen [1].

Capacitive Touch Screens

The other commonly used type of touch screen are capacitive screens. These are the ones used in more expensive devices, like your phone, and are named as such because the entire screen works as one massive capacitor. A capacitor is a basic electronic component that consists of two conducting plates, usually with some other material called a dielectric in between them. When electricity flows into a capacitor, electrons flood into one the plates, but can’t cross because the circuit technically isn’t complete. This causes a buildup of electrical charge on the plates. One plate becomes negatively charged and the other becomes positively charged, and an electric field forms in the area between the two charged surfaces [1].

On a capacitive touch screen, one of these plates is the screen itself. Beneath the outermost glass layer of the screen is a thin coating of a metal called indium tin oxide (ITO). ITO is unique as it is both transparent and electrically conductive, so the entire display surface can be coated with it. Some resistive touch screens also use ITO, but it’s not necessary for them to function, unlike capacitive screens which do require it.

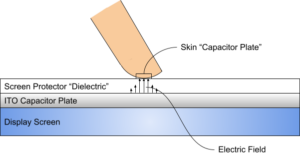

However, a capacitor requires two conducting plates to function. The first is the ITO capacitor plate hidden just below the screen protector. The second plate is you. Or more specifically, whatever you touch the screen with, usually your finger. You see, you can conduct electricity. Some electricity. Very little. But crucially, you conduct a noticeably greater amount of electricity than something like air or cloth. When your skin touches the screen of your phone, it completes the circuit on its surface. Once contact is made, your skin becomes the second conductive surface and a capacitor is formed, with a layer of screen protector serving as a dielectric in between. As with all other capacitors, an electric field is generated in the area sandwiched between your fingertip where your skin “capacitor plate” and the ITO capacitor plate overlap [2].

Figure 2: Cross section of electric field generated by a capacitive touch screen

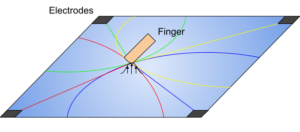

Now that we have that tiny electric field, there are multiple ways to convert it into a signal for a computer. The simplest way is to have electrodes located on each corner of the screen. The electric field is formed where your finger touches the screen, but it does extend further beyond that, with the strength of the field rapidly diminishing the further you get. Those electrodes on each corner can measure the electric field strength to determine its distance from that corner. The location of each electrode is known, so once the distance between the field created by your finger and each of them is known, you can draw a circle of that distance from each electrode, and the spot all 4 circles intersect is where your touch is located [3].

Figure 3: Corner electrodes measuring location of electric field

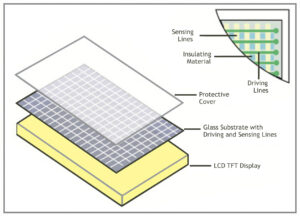

There’s also a more advanced way to sense where the electric field is located. Instead of having electrodes at each corner measuring distances, you can also run tiny transparent electrodes called sensing lines across the entire screen by arranging them in strips to form a grid. This grid is located above the charged ITO layer, but below the glass of the screen. Once your finger makes contact and creates that electric field, the field permeates through the sensing lines, which tells the computer they’re hooked up to exactly where on the screen you touched, making this type of screen more precise [3]. These sensing lines can also be laid out in different patterns to increase resolution even further.

Figure 4: High resolution capacitive touch screen with sensing lines [2]

Of course, those tiny electrodes are fairly expensive to manufacture; smartphones don’t come cheap for a reason. That’s why capacitive screens aren’t used outside of expensive consumer electronics.

Unlike resistive touch screens, capacitive screens also function on contact and don’t require any force to activate, since you don’t need to push on the screen and force the outer layer to flex. The capacitive screen is rigid. This is why you can very lightly tap your phone to use it and why it doesn’t have that weird feeling like the grocery store pad.

The fact that the capacitive screen relies on you to create a capacitor using your skin as a conductor has its own side effects as well. Your smartphone acts all weird when your screen gets slightly wet because water also conducts a small amount of electricity. Even tiny droplets can trick the screen, because from its perspective, it detects something electrically conductive forming a capacitor. When phones advertise that they are waterproof, their computers are just calibrated to ignore electric fields it thinks are generated by water droplets.

Since the screen requires a conductor to register a touch, non-conducting materials touching the screen also won’t cause it to register. This is why you can’t use a smartphone while wearing gloves. Capacitors work by having two conducting surfaces separated by a non-conducting material, but the strength of the electric field is also dependent on the distance between the two surfaces. If the glove is too thick, an electric field strong enough for the device to register as a touch doesn’t form. Gloves whose selling point is that you can use your phone while wearing them work because the fingertips on those gloves can conduct enough electricity to form a capacitor with the phone’s screen in place of your finger. This same principle is also used for styluses, whose tips are specially designed to be able to cause that electric field so the screen registers the stylus as a touch [1].

These are two of the most common types of touch screens, but there are others. The infrared touch screen creates a grid of tiny infrared lasers across the surface of the screen, and once anything touches the screen, it blocks some of those lasers, and the location of the touch can be determined by which lasers were blocked.

A Stagnant Future?

These days though, the touch screen has gone from novel to mundane, and the technology is quite mature. For the average consumer, expect improvements to be marginal, as the electrode patterns continue to get refined [3]. There are still a few developments in the works though. The most prominent innovation is replacing the ITO in most capacitive touch screens with other materials such as a silver polymer so the screen can effectively “heal” itself from scratches to improve the working life of the device [4]. Beyond that, the underlying touch detection technology has the potential to be expanded across just about anything. Since the touch component is separate from the screen itself which lies underneath, any electronic device could theoretically be touch interactive. Some newer smartphones are experimenting with flexible screens. Right now, this appears to be mainly driven by nostalgia for flip-phones, but as the material science behind it develops, it may become possible for most surfaces to become interactive. Expect tiny electromagnetic field-detecting strips to continue to proliferate into more and more of our daily lives for years to come.

Sources:

[1] TRU-Vu, “Touch screen basics,” TRU-Vu, 18-Nov-2020. [Online]. Available: https://tru-vumonitors.com/touch-screen-basics/. [Accessed: 04-Feb-2022].

[2] Newhaven Display, “Capacitive Touch Panels,” Newhaven Display International, Inc. [Online]. Available: https://newhavendisplay.com/appnotes/touchpanels/cpt_v_res.php. [Accessed: 04-Feb-2022].

[3] J. Lee, M. T. Cole, J. C. S. Lai and A. Nathan, “An Analysis of Electrode Patterns in Capacitive Touch Screen Panels,” in Journal of Display Technology, vol. 10, no. 5, pp. 362-366, May 2014, doi: 10.1109/JDT.2014.2303980.

[4] J. Li, J. Liang, L. Li, F. Ren, W. Hu, J. Li, S. Qi, and Q. Pei, “Healable capacitive touch screen sensors based on transparent composite electrodes comprising silver nanowires and a furan/Maleimide Diels–alder cycloaddition polymer,” ACS Nano, vol. 8, no. 12, pp. 12874–12882, 2014.