3D printing is the process of building up a 3D object by depositing materials layer by layer onto the print bed of a 3D printer. The materials most commonly used to produce the 3D objects have been plastics and metals, but recently researchers, engineers, scientists and food connoisseurs have begun to experiment with edible materials. These professionals have started to create 3D printers for the sole purpose of printing food. This paper will discuss how the use of edible ingredients can unlock the creativity of the food industry, feed future astronauts in space, and soldiers on the battlefield, and solve some of the problems the world is currently facing. First, this paper will explain the engineering behind 3D printers. Then it will describe the current state of 3D food printing technology. Next it will discuss the goals for 3D food printing in the future, and lastly, it will conclude with the challenges and limitation of this new technology.

Introduction

3D printing has become a recent phenomenon due to a 2012 market divergence [1]. With the touch of a button, one has the ability to create almost anything imaginable with a device approximately the size of a microwave. The history of 3D printing began when the first 3D printer was patented in the 1980’s. Throughout its short history, its main function has been for industrial applications using mainly plastic and metal materials [1]. However, in 2012, a team at Cornell University started to experiment with hydrocolloids – a gel-like substance infused with flavors and textures to replicate solid foods [2]. Other 3D food printer companies have ventured into creating desserts with edible ingredients such as chocolate, sugar and candy. And recently, 3D food printers have been able to use batters and dough to print foods such as pizza, pasta and cookies. Even though 3D printed food is still in its infancy — constrained to ingredients that can be deposited out of a small nozzle — there is a lot of hope and speculation about where this new phenomenon will take the food industry, including creating beautiful, intricate edible creations, feeding our astronauts in space and soldiers on the battlefield, customizing foods, and helping with world hunger and food sustainability.

The Engineering Behind 3D Printing

3D Printers have both software and hardware components that work together to create the 3D designs.

Software

Before 3D printing can begin, a virtual design of the object must be created. This can be done in a Computer Aided Design (CAD) file using a specialized 3D modeling program or the using a 3D scanner [3]. The software slices the virtual object into thousands of horizontal layers, and then uploads the object onto the 3D printer. The printer sets down the edible ingredients layer by layer to create the 3D design [3].

Hardware

There are three major mechanisms that make up the hardware of a 3D printer: The print bed, the gantries and the printing head [4].

The Print Bed:

This is the component upon which the object is printed. The different materials, whether they are plastic or edible, are deposited layer by layer onto the print bed to make the printed model.

The Gantries:

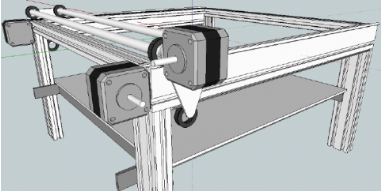

The three gantries as shown in Fig. 1, navigate three axes of the 3D printer and can be compared to an arcade claw game [4]. The gantries located on the x- and y- axis navigate the horizontal plane and are equivalent to the left-to-right and forward-and-backward movement of the claw, respectively. The gantry that moves along the z-axis is similar to the up and down motion of the claw, and is responsible for building the depth of the object [2].

In order for the gantries to create 3D designs, they are equipped with stepper motors that allow them to make precise movements. The stepper motors are controlled by digital pulses, in which “each pulse only moves the motor a small fraction of a full rotation”[4]. These small movements enable the gantries to create intricate and detailed 3D designs [4].

The Printing Head:

The printing head, shown in Fig. 2, is attached to the gantries and is responsible for setting down the edible ingredients layer by layer onto the print bed [3]. The edible materials are placed inside capsules that are mounted onto the print head. The ingredients are slowly extruded through the nozzles, similar to decorating a cake with icing.

The World of 3D Printed Food

Printing food is still in its infancy, constrained to ingredients that can be deposited out of the small nozzles. Even though there are limitations to this process, this has not stopped professionals from venturing into this new territory and creating 3D printers for the sole purpose of printing food. Through the use of ingredients such as hydrocolloids, chocolate, sugar, batter and dough, these 3D printers have been able to mimic solid foods and help professionals unlock their creative potential. Despite the fact that 3D food printers have yet to hit the commercial market, this technology will impact the way the world views and eats food.

Hydrocolloids

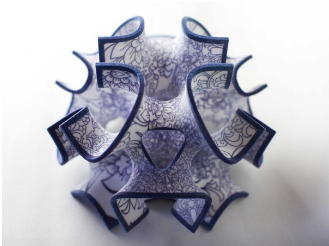

In 2012, Hod Lipson and Evan Malone, who lead the team at Cornell Creative Machines Lab, began experimenting with Solid Freeform Fabrication (SFF) of food with the use of hydrocolloids. Hydrocolloids, shown in Fig. 2, are gel-like substances made of xanthium gum, a thickening agent, and gelatin [2]. They are combined with different flavors and textures to mimic solid foods such as bananas, mushrooms and mozzarella cheese [2,6]. The goal for hydrocolloid printing is to both enhance the culinary profession and positively impact food production at home. Culinary professionals are constantly looking for innovative ways to experiment with their craft. With the help of a 3D food printer, a professional can create a cake that displays a personal message upon cutting into said cake. [2]. Another application for food-Solid Freeform Fabrication is to one day assist the cooking process at home. According to the USDA, the average American spends more than 30 minutes per day preparing food and that number grows depending on family size. With food-SFF cooking time could be reduced with a “set-and-forget” feature. [2].

Sugar, Chocolate, and Candy

There are a number of 3D food printers that have been developed to create intricate sweets with ingredients such as sugar, chocolate and candy. Fig. 3 is an example of a detailed design made with a 3D printer and sugar [7]. The materials start out liquid and as they are extruded layer-by-layer onto the print bed, they begin to harden, building a stable 3D design [8]. Similar to the team at Cornell, these 3D printer inventers hope to unlock the imaginations of culinary professionals [7]. This technology allows bakers to create detailed cake toppers or restaurateurs to craft colorful cocktail decorations. One company has partnered with the Culinary Institute of America to provide students and teachers the opportunity to experiment with this new technology to incorporate it in future culinary creations. [9] These 3D printers also aim to appeal to a mass consumer base by being user-friendly. One 3D printer, which is expected to be commercially available in the second half of 2015, comes with specialized software that makes it easier for users to design a 3D creation [10].

Other 3D food printing companies have begun to print with materials such as batter and dough to create pizza, pasta and cookies [11]. But, current 3D food systems do not have the ability to cook these food items so they must be cooked in a secondary source, such as an oven [11]. Clearly printing food is still in its early stages but there is a lot of hope for the future.

The Hope for the Future

NASA

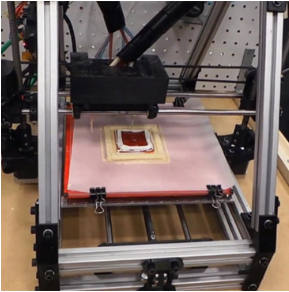

NASA has awarded a six-month, $125,000 grant to a Texas Company, Systems & Materials Research Cooperation, to create 3D printing technology to feed future astronauts in space. NASA hopes to venture farther into space than what has previously been explored, but unfortunately these long duration flights are not possible with the current food system. The food only has a 5-year shelf life and would not provide the necessary nutrients needed to support astronauts on a mission to Mars, for example [12]. NASA hopes that with 3D printing technology, long exploration missions will be made possible. 3D printing in space would allow food to be mixed with vitamins and amino acids to provide the necessary nutrients for astronauts. [6] The 3D printer plans to utilize cartridges filled with carbohydrates, sugars and protein that can last up to 30 years, due to the sustainability of the ingredients [13]. Lastly, this technology will allow for maximum use of spacecraft resources by taking up less space than the current supply of packaged food. [6] It is important to note that SMRC has created its first printed food, pizza, as shown in Fig. 4, making NASA one step closer to feeding astronauts in space [13].

The Army

Similarly to NASA, the U.S. Army is looking to 3D printed food technologies to feed their soldiers on the battlefield. Lauren Oleksyk, a food technologist at the Army’s Natick Research center, explained that their vision is to tailor the 3D printed food to the nutritional needs of individual soldiers [14]. Their goal is to equip soldiers with head-to-toe sensors that can relay information to 3D printers. The 3D printers would then produce personalized meals for the soldiers depending on their body’s dietary needs [14]. For example, the sensor would detect that a specific soldier is low in vitamin B. The 3D printer will receive this information, and then create a vitamin B rich meal for that individual soldier. Another advantage of 3D printing technology is that the food cartridges do not need to be refrigerated. This provides a crucial benefit to soldiers on the battlefield [14].

Customization of Your Food

A number of 3D food printer advocates believe that this technology will become a standard kitchen appliance in the future [15, 16]. With a 3D food printer people will have complete autonomy over the food they put into their bodies. In the same fashion as the U.S. Army, people could wear sensors that would connect to a home 3D printer to create customized meals based on the user’s individual nutritional needs [15]. Not only could people embed specific nutrients in their food, but also have control over the shape, flavor, consistency and color [16]. The possibilities are endless; imagine creating pasta in the shape of a rose for Valentines Day, or printing a cheeseburger with the onions, cheese and ketchup in the middle of the patty – a picky eater’s dream come true.

World Hunger and Sustainable food

As the world’s population grows, scientists and researchers are looking to 3D printing to not only help with world hunger but for a sustainable food source as well. Anjan Contractor, a mechanical engineer at Systems & Materials Research Corporation, believes the food printing technology he is creating to feed astronauts in space could also help feed the world. He explained, “The nutrient cartridges can last up to 30 years, so they eliminate waste, particularly in quick-rotting environments like Africa, South America, and Asia.”[13] Other researchers like Kjeld van Bommel have suggested similar uses for 3D printers. He explained that if Western consumption spreads to the rest of the world, 3D printers may be the answer to sustaining this growth by transforming other proteins like algae and insects into food people would want to eat [15].

Challenges and Limitations

Because printing food with 3D technology is still a relatively new innovation there are inevitable challenges and limitations that come with this 3D printing technology. One of the biggest challenges is the limitation of materials that can be used to create 3D printed food. Right now the ingredients are constrained to specific consistencies that can be extruded out of a small nozzle [7]. Another limitation is that current 3D printers cannot cook the food, restricting the food you can print. However, some speculate that in the future 3D printers will be equipped with lasers enabling the printer to cook the food [16]. An additional challenge is the price; some companies believe that 3D food printers can and should replace microwaves [11] that are priced as low $50. Unfortunately, because this is a new innovation 3D food printers are not at this price point yet, and can range from $500 to as much as $10,000 [8].

Conclusion

Even though 3D printing food is still in its infancy many companies have already gained a lot of attention for embracing this innovative approach to the food industry. Not only is 3D printing an exciting new way to experience food it can also solve some problems we are currently facing. These include feeding astronauts in space and soldiers on the battlefield, customizing food to our nutritional needs, and potentially helping with world hunger and food sustainability. It is clear that 3D printed food has started to make a mark on our society and will most likely continue to innovate to reach the future goals.