From perfecting the coffee bean preparation process to creating the various machines used to brew the java, it has taken hundreds of years of scientific knowledge and engineering to bring the process of coffee making to the state it is in today. Creating new systems for roasting coffee beans requires that many chemical and mechanical engineering issues be considered. Another area of bean preparation in which mechanical engineering has played a role is in the grinding process. Nevertheless, the area of coffee making where engineers have had the most influence is in the development of machines and systems for brewing coffee. Perhaps the most sophisticated and difficult to understand contraption ever engineered for coffee brewing is the espresso machine. The main advance in the engineering of the espresso machine came in 1961, when the first espresso machine with an electric pump was introduced. This advance allowed for the automation of coffee making. Engineering has had a huge impact on the many aspects of coffee making including, roasting, grinding, and brewing.

Introduction

Only one word hangs in the minds of millions of people when they wake up every morning: coffee. According to the Bellissimo Coffee Infogroup, 400 billion cups of coffee are consumed annually around the world, making coffee second only to water as the most popular beverage [1]. Coffee is everywhere we go, and yet, because of its prevalence in our society, many people take the drink for granted. We might be surprised to learn just how much science and engineering goes into just a single cup. Many engineering fields, from chemical to mechanical engineering, have had huge impacts on the development, preparation, and brewing techniques. From perfecting the coffee bean preparation process to creating the various machines used to brew the java, it has taken hundreds of years of scientific knowledge and engineering to bring the process of coffee making to the state it is in today.

The Background of a Bean

Coffee beans, seen in Fig. 1, are actually the seeds of a cherry that grows on evergreen trees. According to African legend, coffee was first discovered in the area we know as Ethiopia by a goat herder. This man supposedly noticed that his goats were much more lively and active after eating the coffee cherries from a small tree. He tried the berries himself and found they gave him more energy [1]. As word spread about the cherry, more and more people wanted to be able to taste the fruit, but distance limited those who could actually try it. This changed when people began drying the cherries to export them to distant areas. When the cherries arrived, they would be soaked in water for reconstitution and people noticed that the water also provided some stimulation. Thus, the first coffee made was discovered by accident. This coincidence led people to the realization that soaking many seeds of the coffee cherry in water and drinking it was more effective than eating the fruit itself and much more practical for export [1]. Whether or not this legend is true, by the 1400s coffee was beginning to find wide use in Persia and had been used in Ethiopia for “timeimmemorial” [2]. Coffee was introduced to the court of Louis XIV in 1669 by a Turkish ambassador, and the beans were soon exported all over Europe, with coffee plantations being established in European colonies [3].

It may seem that very little engineering is involved in the history of coffee so far. However, in the development of processes for preparing the coffee beans for brewing science and engineering were about to have a great and unforseen role. In order to get as much flavor out of the beans as possible, it was discovered that roasting the beans was required. This practice began in Turkey [1]. Roasting brings oils inside of the bean to the surface, giving the beans their aroma. This aromatic oil, known as caffeone, consists of over 600 different chemical substances, many of which are very delicate. To extract a good flavor from the beans, the roasting process must be done so that the unstable chemicals in the caffeine are not burned away [4]. Because of the delicacy of the chemicals, it is important to have a consistent and precise process of coffee bean roasting where the beans are neither under, nor over, roasted.

Methods for roasting coffee beans have been further developed over the hundreds of years that have passed since roasting first began and this phenomenon has occurred because of science and engineering. While the original method of roasting the beans by allowing them to cook in the sun was not an efficient method of roasting, today’s methods of bean preparation are much more scientific and effective.

Engineering and Preparing the Bean

When creating new systems for roasting coffee beans, there are many chemical and mechanical engineering issues that need to be considered.

The inside of the bean must be roasted just as the outside is, but the bean must not be overcooked, or it will lose its flavor. The reason why over-roasting could lessen the taste of the coffee beans was unknown to man for hundreds of years, but technology today has provided us with answers. Since the chemical substances within the bean are released during the roasting process, flavor in the bean is lost if roasted for too long. As a result, the machines invented for roasting the coffee beans must have very sensitive heat and timer sensors. Also, the beans must be cooled promptly after leaving the roasters, because if they remain hot, the ambient heat generated by the beans would continue cooking them, even while they are out of the roaster. In general, the beans are usually cooled down with water or cool air [4]. Engineers had to come up with systems to deal with all of these factors in the bean roasting process.

The two major methods of coffee bean roasting used today are drum roasting and hot air roasting. Drum roasting is one of the older of the popular methods used today to roast coffee beans. Mechanical engineers designed these machines to function as follows: the beans are loaded into large circular drums, and then rotated. As the beans tumble in the drum, they are roasted by heat from wood or gas fires [1]. The rotating drum is very important, because it ensures that the beans are evenly roasted. Once the “desired roast is achieved, the beans are poured into a cooling hopper to keep them from overheating” [1].

Hot air roasting, or fluid-bed roasting, is a newer form of coffee bean roasting that has been developed by mechanical engineers, is depicted in Fig. 2. Instead of keeping the beans in large vats, they are roasted while floating on a stream of hot air. As they tumble around on the hot currents, the beans are evenly roasted [1]. In both of these systems, machine operators can closely monitor the amount of time and heat at which the beans are cooked.

Another area of bean preparation in which engineering has played a large role is in the grinding process. In order to maximize the amount of coffee that can be created from a bean, grinding was developed. Since grinding results in more surface area from the same amount of bean, more coffee can be brewed from fewer beans. The brewing method being used determines how fine the grind of the coffee must be. This is because the amount of time the water will be in contact with the coffee during the brewing process determines how many oils will be extracted from the coffee. Course grounds are used when the water will be in contact with the grounds for a long amount of time. Fine grounds are used when the water will only be in contact with the grounds for a very short time. For instance, coffee to be used in a French press needs to be larger and courser than coffee used in a drip machine. Espresso needs to be made with very finely ground beans, because the water is only momentarily in contact with the grinds. Grinding machines have been created to deal with these issues.

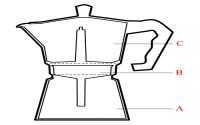

In order to grind different types of coffee, the machines must be able to change the size of the grind. These machines generally consist of the bell, the grinder, and a measuring device [4]. The bell is a chamber that holds the whole beans before they are ground. The grinder is a pair of metal disks with teeth around the edges. These discs can be moved closer or further apart, depending on how course or fine the grind needs to be. Finally, the measuring device is where the grounds land and this portion of the device also indicates the amount of coffee you have just ground [4]. These grinding devices can be hand cranked or run on electricity.

Engineering and Brewing the Java

The old method of making coffee by soaking coffee beans or grounds in hot water has been greatly changed by engineering. The new methods are based on this original process, but each method has added more mechanical engineering principles to the practice of making coffee. The main engineered systems for coffee brewing (in order of complexity) are the French press, the drip brewer, and the espresso machine. The French press is the oldest of the three main methods. The French press, in Figure 3, consists of a cylindrical pot containing a metal plunger with a filter that fits to the sides of the pot. Very coarsely ground coffee is mixed with hot water in the pot, and after being allowed to mix for a few moments, the plunger is depressed. The slits in the filter on the end of the plunger are small enough that the course coffee grounds cannot slip through. Thus, the coffee is separated from the grounds [5].

While this does not seem to have required much engineering, upon examination the French press actually required a lot of thought. The common method of coffee making before the invention of the French press was just letting the grounds soak in hot water and then pour the coffee carefully into another pot to avoid drinking grounds [5]. By adding the plunger and filter to the process, the problem of drinking grounds was eliminated and the need for a second pot was removed.

Building further on the concept of simplifying the coffee making process, another system was engineered, the drip system. This system is generally more complicated than the French press, as there are more parts to worry about, and because the machine usually warms the water. The basic idea behind the drip system is as follows. Water is poured into the top of the unit. Then, when warmed, the water flows through a paper or metal filter that holds the coffee grounds. Gradually, it passes through the grounds and into a coffeepot where it has transformed from water to hot coffee. The force behind this system is gravity. Gravity pulls the water down through the filter and the grounds and into the pot [5]. Again, this doesn’t seem like much of a feat in engineering, but it is a huge improvement over the French press. While the French press is based on the operator depressing the filter, the drip system uses gravity. The water does not need to be preheated before going into the machine; the machine was created to do that. The coffee does not need to be strained by depressing a plunger with a filter into a pot; the machine does it for you. There is no need to worry about whether grounds will get through the filter into your coffee; the machine does it for you. The drip system reduced the amount of manual work to simply changing the coffee grounds and filters and loading the water.

Perhaps the most sophisticated and difficult contraption to understand engineered for coffee brewing is the espresso machine. As anyone who has tried brewing espresso knows, the process resembles science more than culinary art. In order to make a good cup of espresso the right balance between temperature and pressure needs to be used to transfer the coffee’s nutrients into the espresso [4]. Instead of using gravity to get the nutrients into the water like a drip machine, an espresso machine uses water at high temperature and shoots it at high pressure through the coffee grounds [4].

Depending on the machine, the method of shooting the water through the grounds varies. The original espresso machines just boiled the water so it was steam that traveled through the grounds [6]. This process caused the espresso to have a burnt flavor. In 1938 an espresso machine with a piston pump was introduced. This new machine forced hot water through the coffee grinds by having the operator use a hand pump that built up pressure in the water chamber, forcing it up through the grounds [6]. This not only resulted in better tasting espresso, but also gave the coffee a layer of foam on top. This foam is now a trademark of good espresso.

The most significant advance in the engineering of the espresso machine came in 1961, when the first espresso machine with an electric pump was introduced. In this design, water is pumped in from a fresh supply and travels through a thin tube [6]. The water passes through the boiler, which, as physics tells us, quickly heats the water in the tube because of the small volume traveling in the portion of the tube affected by the boiler. The water is then brought through the coffee grounds. This design of espresso maker eliminates the need for manual labor. With a few added bells and whistles such as automatic grinding of beans and frothing of milk, this is essentially the design in use today.

Conclusion

From helping create better bean preparation processes to helping automate the coffee making process, engineering has defined the modern methods of coffee making. For more information on the history of coffee, visit Coffee Universe [1]. And the next time you enjoy a hot cup of java, remember that it is hundreds of years of science and engineering that are to thank for your enjoyment of this wonderful and popular beverage.