Body armor, both soft and hard, has gone through extensive changes over the years, especially in the past century. Soft body armor, constructed out of materials such as Kevlar, uses layers of synthetic fibers to stop a bullet. Hard body armor, composed of hard ceramics like boron carbide, shatters a bullet at its surface. A combination of soft and hard body armor is used by law enforcement personnel and militaries around the world to protect those in harm’s way. This duo of protection is continually being improved by new technologies and advances in materials science, granting better protection to those who protect our lives.

Introduction

December 14, 2003, began like every other day in Iraq for Pfc. Gregory Stovall. That morning, the 22 year old Brooklyn native was participating in a routine mission guarding a convoy of trucks delivering mail. He stood in the turret of a lead Humvee, manning a .50 caliber machine gun. As the convoy approached its destination, a roadside bomb detonated, ripping through Stovall’s Humvee. His face was hit with searing shrapnel and his fingers suffered severe lacerations. Shrapnel hitting his chest, stomach, and back knocked the wind out of Stovall and left him in a state of shock.

Stovall was sure that the end was near and instinctively reached for his stomach and chest, expecting to find mortal wounds; instead, he found that his Interceptor body armor had absorbed the impact and power of the blast. Pfc. Gregory Stovall is just one of many soldiers, sailors, and marines who have been saved by their body armor in Iraq and Afghanistan [1].

The importance of good body armor cannot be emphasized enough. Effective body armor is essential to protecting our fighting men and women both at home and overseas, ensuring the completion of their mission and their safe return home (Fig. 1). New, exciting technologies show great potential to significantly enhance current body armor.These technologies include the use of liquid armor to augment current Kevlar systems, the use of novel materials including boron carbide and spider silk, and even the study of natural armor, such as that found in abalone shells. All of these technologies are aimed at creating body armor that will allow domestic and overseas personnel to complete their missions in a safe and effective manner.

A Brief History of Body Armor

Body armor has been in existence for thousands of years. Early man used tough animal hides to protect from the sharp teeth and claws of predators [2]. Eventually, as civilization continued to advance, more effective body armor was created to counter the threat posed by edged weapons. The Roman military used three types of body armor: mail, scale, and segmental armor. Mail consisted of an interlinking system of iron rings; scale armor was made of small plates of copper or iron alloy wired together and sewn to a leather backing; and segmental armor overlapped curved bands of iron fastened to internal leather straps [3]. The Japanese samurai used a similar type of protective armor made out of silk [4]. Both Roman and Japanese Samurai body armor were highly advanced for their day.

During the early middle ages, leather armor and chain mail were commonly worn to protect the user from edged weapon attacks. By the late 1300’s, full plate armor became widespread [5]. Full plate armor was nearly impervious to sword blows and also provided protection against arrows, bludgeons, and early musket and pistol shot, all of which were of a relatively low velocity [6]. Over the next century, plate armor was slowly discarded to save weight on the battlefield. According to Derek Leebaert, Georgetown Professor and former Smithsonian Fellow, during this time, “the simply made, easy to use, armor-piercing ‘hand gonne’ would begin doing its part to end the role of the knight.” In fact, by 1750, most forms of plate armor were discarded as advances in firearms technology allowed rifled musket shot to easily pierce plate armor [6].

After the development of the rifle and the obsolescence of plate armor, little or no body armor was used for over a century. It was not until the end of the 19th century that the first types of bullet-resistant body armor came into the picture. The Rev. Casmir Zeglen of Chicago, Illinois, created a vest made out of silk fabric near the end of the 19th century. Unfortunately, this vest was expensive and largely useless, able to stop only slow moving rounds from black powder handguns. During World War I, the United States developed a few different types of body armor, including the Brewster Body Shield. However, the Brewster Body Shield and other armor of the time were very heavy (weighing over 40 pounds), uncomfortable, and largely ineffective [7]. During World War II, the use of body armor by infantrymen was discontinued because of its weight and incompatibility. The only armor worn during this time was that by aircrews who wore “flak jackets,” capable of stopping only flak and shrapnel but not direct hits from projectiles [8]. During the Vietnam War, soldiers and marines on the ground wore improved versions of the flak jacket. This type of armor was effective at stopping grenade fragments and other indirect effects of bombardment but was still powerless against direct hits from small arms fire [9].

During the late 1960’s, the National Institute of Justice (NIJ) instituted a research program to develop a lightweight body armor system able to be worn full time by law enforcement officers (Fig. 2). The program revealed several materials that could be woven into a lightweight fabric, which provided excellent bullet resistance [10]. One of the materials proven to provide effective bullet resistance was Kevlar. This fabric, created in 1965 by DuPont scientists, was originally designed to replace steel belting in vehicle tires. Kevlar is a synthetic fiber of poly-paraphenylene terephthalamide made up of long polymeric chains with a parallel orientation. Kevlar derives much of its strength from intermolecular hydrogen bonds complemented by van der Waals forces of attraction [11].

In order to validate the usefulness of Kevlar, the NIJ tested it in a four phase process over a period of several years. The first phase involved testing Kevlar fabric to determine its effectiveness at stopping a lead bullet. The second phase determined the number of layers of fabric necessary to stop bullets of varying speeds and calibers. By 1973, at the end of the second phase, a preliminary Kevlar vest prototype with seven layers of Kevlar fabric was created and further tested to determine its resistance to environmental agents such as water and light. The third phase of testing evaluated the performance level of body armor necessary to save human lives. The final phase of testing monitored the Kevlar vest’s wearability and effectiveness in the field. Testing concluded in 1976 with a determination that Kevlar was effective as a bullet resistance garment. Subsequently, the material was cleared for full-time use by law enforcement officers [4].

Modern Body Armor

Most modern soft body armor is still constructed out of Kevlar. From the early 1980’s to 2004, the U.S. military utilized a Kevlar body armor system in its Personnel Armor for Ground Troops Vest. However, new fabrics have been developed since the advent of Kevlar and have proven more bullet resistant. Examples include Dyneema, Spectra, Twaron, and GoldFlex [4]. Dyneema is advertised as being 15 times stronger than steel and up to 40% stronger than Kevlar. The main reason many of these materials have not garnered widespread use is that they are much more expensive than traditional Kevlar [7]. Despite this, materials such as Dyneema have been reportedly used in modern combat vests such as the Interceptor Body Armor System [12]. The system, now issued to all U.S. military personnel in Iraq and Afghanistan, consists of an Outer Tactical Vest (OTV) constructed out of Kevlar KM2 and two Small Arms Protective Inserts (SAPIs) [13]. The SAPIs are constructed out of boron carbide ceramic with a Dyneema shield backing. The OTV provides protection against shrapnel and some small arms fire while the SAPIs protect the user against rounds of up to 7.62x51mm [14].

How Body Armor Works

The engineering behind body armor is simple yet fascinating. Most hard body armor is constructed out of high-tech ceramic, such as silicon carbide or boron carbide. These high-tech ceramics are used in place of metal because they are significantly lighter. When a bullet hits ceramic armor, the bullet shatters at the ceramic surface and the bullet fragments are trapped by the backing fibers [15].

Soft body armor functions in a completely different manner. Rather than shatter the projectile, soft body armor operates like a net to absorb the momentum from a bullet and stop it before it can penetrate the user. A simple way to think about it is to visualize a net used to catch people who fall from large heights. This net is usually made of a strong, flexible material fastened to a steel structure. Long lengths of tether from the net are interlaced and intertwined to support the person when he falls. As the falling body leaves the building, it picks up a substantial amount of kinetic energy and downward momentum. This kinetic energy peaks just before the person hits the net. As the person hits the net, lengths of tether at the impact point are pushed back and out. Rather than concentrate all of the kinetic energy at single point, the lengths of tether disperse the energy of the falling body over a wide area. The momentum of the body is further reduced by the interlacing of the net. When the body impacts the net, it presses downward on horizontal lengths of tether, which pull downward on interlaced vertical lengths of tether. The vertical lengths of tether pull down on all connected horizontal tethers; therefore, the entire net is utilized to reduce the kinetic energy and momentum from the fall [16].

When placed under a powerful microscope, materials such as Kevlar and Dyneema look like a dense net. Long strands of fiber extending over the length of the vest are interlaced to disperse the bullet’s energy over a wide area. To reduce blunt trauma injuries, the material making up the vest must be very tightly woven. In addition, the fibers are often twisted to increase their thickness and density at each point. The rigidity of the vest can also be increased by coating the Kevlar mesh with resin and sandwiching each layer of bulletproof material between pieces of plastic film.

Multiple layers of bulletproof material are used to slow down the bullet and cause it to deform [16]. Once the bullet is deformed, it spreads out at the tip and further dissipates its energy over a wider area. This effect, referred to as mushrooming, drastically lowers the chance that the bullet will pierce the vest [4]. While no vest is truly bulletproof, the focus of all of these measures is to reduce the bullet’s kinetic energy and momentum over a wide area.

The Future of Body Armor

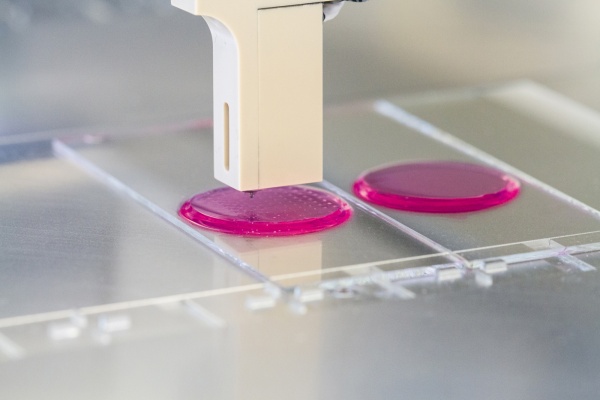

New advances in materials science have shown great potential to improve current soft and hard body armor. Recent studies have focused on the development of liquid armor to improve and enhance current soft body armor. Liquid armor consists of nano-particles of silica and other larger hard particles mixed in a non-toxic fluid, polyethylene glycol. This mixture gives liquid armor a number of unique properties, namely that of being a shear thickening fluid. To enhance soft body armor, the fluid is soaked into all layers of the Kevlar vest [17]. Once in place, the fluid “changes how the fabric architecture interacts with an object [18].” At low strain rates, liquid armor flows like a fluid and does not compromise the flexibility of the vest. At high strain rates (when a bullet or knife impacts the vest), the particles within the fluid become rigid and restrict the ability of the fabric to move. This property causes the fabric to stay in front of the bullet or knife and significantly enhances its stopping power against both projectiles and sharp objects. Once the stress is relieved, the particles will lose their rigidity and the liquid armor will revert to being a flexible liquid. While this exciting technology is still in the research and development phase, it could see use in the U.S. military within two years [18].

On the more distant horizon, scientists at the University of California San Diego are looking at biomimetric or biology-inspired solutions to create new body armor. Specifically, they are looking at how animals such as abalone create their hard outer shell. According to Dr. Marc A. Meyers, a professor in UCSD’s Jacobs School of Engineering, “a careful examination of the steps taken by abalone to make their shells may help materials scientists develop similarly lightweight and effective body armor for soldiers, police, and others…The laminate structure of abalone shell has stimulated our group to develop a new synthetic material using this lowly mollusk as a guide” [19]. At the nanoscale, abalone shell is made up of thousands of sheets of calcium carbonate tiles connected by a strong protein adhesive. The precise way that these tiles are assembled determines their strength. Dr. Meyers and his team hope to discover exactly how the layers of tiles are constructed so that others may use his mathematical models to create superior body armor based on nature’s design [19].

Researchers across the globe are attacking the issue of body armor from other angles as well. Scientists at the Hebrew University in Jerusalem are looking at the creation of artificial spider silk or dragline silk. Dragline silk is the strongest and most flexible of the silk fibers and is six times stronger than conventional silk. These scientists are focusing on introducing genes that encode the major dragline silk proteins into an insect-infecting virus. This engineered virus would be introduced into insect cells in order to produce dragline silk artificially [20]. Researchers at ApNano materials, an Israeli company, have recently used nanotechnology to synthesize a strong ceramic known as Tungsten Disulfide (WS2) in the nano-sphere and nano-tube form. This structure and structures of similar inorganic compounds are known as inorganic fullerene-like nanostructures, or IF for short. Recent tests have shown that this new form of WS2 has up to twice the strength of current hard ceramics, such as boron carbide [21].

The future of body armor is bright and exciting: thousands of scientists and engineers across the globe are working diligently to create better soft and hard body armor. It is vital that these researchers continue to develop and enhance modern body armor, as it is used on a daily basis by armed forces and law enforcement personnel. Ultimately, the goal is to develop a system that will function effectively under the most severe conditions so that as many lives as possible can be saved.