Shoe design is a complex process that involves the collaboration of a variety of individuals, including runners, craftsmen, technicians, scientists, and doctors. This article will focus on the complicated efforts that stand behind a relatively simple piece of athletic equipment: the running shoe.

Introduction

They were dreaming about running . . . Knifing through the wind . . . Sports track fast. Michael Johnson fast. Fast beyond even your wildest dreams [1].

Running: it does a body good. Like any other bodily exercise, it can do wonders for both our physical and mental well being. Perhaps that is why in the past several years the athletic world has experienced a resurgence of runners [2]. Almost simultaneously, the running shoe industry has undergone a similarly dramatic growth.

But amidst this exponentially growing ‘natural’ sport, there is a major concern for all those ground-pounding die-hards: you gotta have the shoes. Runners’ shoes affect their entire body, and consequently are considered their most valuable piece of equipment (Fig. 1). It is essential to find the ‘right’ shoes. Small variations in shoe design have been found to cause ankle pain, back pain, and even headaches [2].

Shoe Engineers

The primary goal of running shoe engineers is to achieve an optimal shoe design for the “average” athlete. Average, in terms of human biomechanics, is a very tricky concept, since all people are anatomically and functionally different [3]. Each individual is unique; differences in structure, movement, and gait pattern require footwear to vary from person to person. Efforts to meet this concern are further multiplied by the critical factors to be considered in the design of each shoe: shock absorption, flexibility, fit, traction, sole wear, breathability, weight, etc. Due to the diversity of the human form, it is impossible to provide for the needs of every runner on the planet. Shoe designers manage this overwhelming demand by supplying some standard, user-defined, foot-ground interface (Fig. 2).

It is important to differentiate between shoe design and shoe fabrication. Shoe design involves the complicated task of finding the most versatile specifications to cover a broad spectrum of biomechanical requirements. In contrast, putting a shoe together once the specifications have been set is a very straightforward process. A typical shoe consists of three basic components: the outsole, the midsole, and the upper. Each of these components is comprised of materials that vary greatly in weight and density. A shoe’s durability is often determined by the hardness of the outsole rubber, the density and firmness of the midsole foam, and the strength of the upper materials.

As simple as the parts may seem, however, running shoe design requires the efforts of several academic fields. It is a very detailed application of podiatry, the study of human feet, and biomechanics, the study of the human body in motion. As Peter Cavanagh puts it, “Running shoes are worn on running feet, and running feet are attached to running legs. Trying to understand the design and construction of running shoes without a clear knowledge of what goes inside and above them would be difficult” [2]. Hence, a comprehensive knowledge of human anatomy is key. The goal of biomechanists is to study complex forces as they act on the body, primarily by applying principles from mechanics and engineering [3]. Applications to running include measuring the movements of limb segments, measuring the forces and pressures underneath the foot and the shoe, and calculating what muscle forces create the observed movements [2].

By studying the motions of an athlete engaged in a sports movement, biomechanical engineers can apply mathematical and engineering principles to derive functional criteria for the problems encountered by the human body in motion [3].

Gait Analysis

Biomechanists utilize a method known as ‘gait analysis’ to evaluate human kinetics quantitatively. These studies are conducted in the laboratory using high-speed photography and a force-measuring platform. In high-speed photography, runners are filmed at speeds up to 500 frames per second. The film is then analyzed by a high grade projector, which moves the experimental film through one frame at a time. In most cases, markers are placed at specific ‘points of interest’ before filming takes place [2]. This new technology is better known as ‘motion analysis.’ As the individual moves about the laboratory, a number of cameras scattered throughout the perimeter of the testing area detect the spatial locations of each of the markers. These markers are placed at locations where important measurements are to be taken, including the hip joint, the back of the shoe, and the back of the leg. A screen displays the markers as dots moving about in a three-dimensional plane. The detected signals are then converted to numerical data for mathematical analysis of each point throughout the running cycle.

The second important tool in gait analysis is the force platform. This device is specially geared to measure variations in forces under the foot during running. Data collected from force platform measurements allow scientists to visualize ‘invisible’ forces acting on the soles of the feet [3]. It is from this device that we are able to observe, for example, that the reaction forces under the foot during running can rise up to two to three times body weight. Pressure distributions throughout the foot can be observed at given points in the running cycle. (For a moving map, see the website for the International Society of Biomechanics: Technical Group on Footwear Biomechanics: http://www.teleport.com/~biomech/sneakers.html) [4].

Shoe Testing

Biomechanics also plays an important role in the shoe testing process. Before the advent of dynamic mechanical methods for evaluating shoe performance, the primary concern of the shoe industry was to test materials for adhesion, attachment, seams, and fatigue due to the structural breakdown of the shoe with use [3]. Biomechanical testing concentrates on the shoe in action and the resulting stresses imposed on the runner.

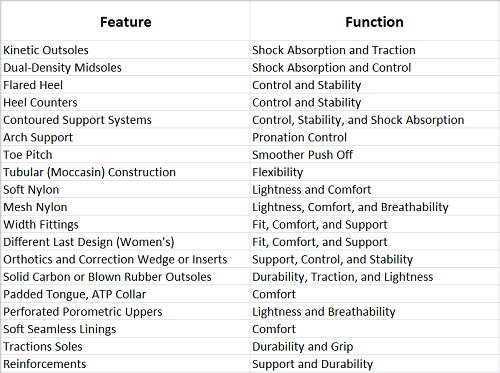

There are several methods for shoe testing. In the general process, advanced technology is used to determine the shoe requirements of runners in motion. Results of the test are analyzed and the opinions and feelings of the runner are considered. These results are combined to produce a shoe that both tests and fits well [2] Factors tested both in and out of the laboratory include shock absorption [2], flexibility [2], heel counter stiffness [2], rearfoot stability [2], overall rearfoot control [2], sole wear test [2], traction (149), and permeability to water [2]. The testing procedures associated with these factors will not be described at length in this article. However, the following image provides a summary of selected running shoe features and corresponding design functions that have resulted from research [3] (Fig. 3).

The initial step in actual shoe fabrication involves the construction of the ‘last.’ The last is what gives a shoe its shape (and the individual his desired fit). It is the form over which the upper is pulled and molded over during manufacture [2]. At the beginning of the design process, the manufacturer sends his specifications to the model maker, who then constructs a three-dimensional wooden model: the last. In shaping the last, the experienced designer is guided by six measurements.

- Ball Girth

- Waist Girth

- Instep Girth

- Long Heel Girth

- Short Heel Girth

- Stick Length (Overall heel-toe measurement on the last)

Most model shops contain tables that list the approximate values of these measurements for each shoe size. The model maker shapes, files, sands, and smooths until these measurements match and the product subjectively reflects the right appearance [2].

This handmade model is then placed onto a ‘copy lathe,’ which generates exact replicas of the same or different size. This device does complete size runs on the model and, in turn, generates plastic versions of the model onto which the shoes are actually made [2].

This design is now sent to the pattern maker, who measures the exact shapes of the various pieces of material comprising the shoe upper. This process begins with the sewing on of a ‘skin,’ or tightly fitting layer of material, which is sliced off according to the way the shoe will be made. He then makes precise drawings of these parts, including a little more space to accommodate seams. His drawings are sent to the manufacturer for use in cutting dies for the finished product [2].

Conclusion

Shoe design, especially running shoe design, is a very precise and complicated process. It is also paramount to the overall health of the end user. The shoes will be used under a broad variety of conditions, by an infinite variation of body types. Who would have thought such a great responsibility would fall on the shabby and smelly old sneaker?