Abstract:

Space exploration is a dangerous yet necessary endeavor humanity must take on to ensure its survival as a species. The conditions in outer space and on other planets are hostile and utterly different from the ones on earth; for humans to survive outside our planet, everything must be reinvented. We need space suits to not freeze or burn in the extraordinary temperatures of outer space. We need helmets to breathe in the low oxygen emptiness of space. To move in other celestial bodies, we will have to reimagine something that has not changed for thousands of years, the wheel. The Curiosity rover has been one of our most excellent tools for understanding our neighbor planet Mars. Nevertheless, within a year of its deployment, it suffered considerable damage to its aluminum wheels. Scientists have recently discovered a new titanium and nickel alloy, nitinol, which has allowed the development of new flexible metal wheels capable of withstanding the harsh Martian terrain. With further development and research, wheels made of super flexible nitinol could help us travel further into the unknown.

Introduction:

On November 26, 2011, NASA, in collaboration with the Jet Propulsion Lab (JPL), launched the Curiosity rover. Curiosity has been active for over 2800 sols (Martian days, which are about 3% longer than Earth days) on the red planet [1]. In its almost ten years of exploration, it has traveled more than 14 miles and provided over 700,000 photographs for engineers and scientists to learn about the Martian surface [2]. Curiosity was and still is a fantastic feat of engineering. However, a decade of hard work has not come without technical difficulties for the Martian robot.

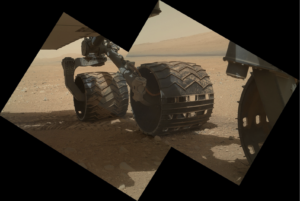

About a year after Curiosity started operations, scientists at JPL noticed the rover’s wheels starting to wear and tear. The harsh Martian surface punctured the thin aluminum wheels, as seen below in [3, Fig 1]. If the wheels continued to suffer this much damage, it would compromise their structural integrity and prevent the Curiosity rover from continuing its exploration mission on Mars.

Figure 1: Damage to Curiosity’s wheels [3]

The Curiosity Rover and its wheels:

Curiosity was the largest of its kind, measuring up to 3 meters long and 2.7 meters wide. Curiosity’s mission was to determine if Mars was ever habitable to microbial life [4]. To undergo this task, Curiosity would need an abundance of scientific equipment. This is why the rover is equipped with up to 17 different cameras, a robotic arm, and even an onboard geology laboratory. All of this scientific equipment makes Curiosity immense compared to its predecessors. The small SUV-sized robot weighs almost one ton at 900 kilograms [3]. All other aspects of the rover were optimized to minimize the weight to allow for such a heavy payload. This is why the wheels of the Curiosity rover are not as massive as the rest of the robot. The material chosen for the wheels was aluminum, a very lightweight metal compared to its impressive ability to withstand stress. The six wheels were milled from solid aluminum blocks to save up on weight from individual pieces. The wheels have a diameter of 0.5 meters, but to save on weight, they are very thin at only 0.75 millimeters thick [5]. To put this into perspective, the average thickness of a credit card is 0.76 millimeters [6]. The wheels of the Curiosity rover, before suffering any damage, can be seen below in [4, Fig 2].

Figure 2: Curiosity’s wheels before damage[4]

Understandably, running the nearly one-ton vehicle on jagged rocky terrain would cause tremendous strain on the slim wheels. Over time the wheels have been scratched, cracked, and even punctured, as seen in [3, Fig 1]. In an interview in 2014, Curiosity’s project manager Jim Erickson explained that NASA expected some wear and tear to the rover’s wheels. However, it underestimated how grueling the Martian terrain would be near Curiosity’s landing vicinity [7]. The severity of the damage to the rover’s wheels greatly worried the engineers behind its development. These worries sparked conversations about necessary innovations for future Mars missions.

A more flexible material would have been better for the wheels of the rover, one with the capacity to adapt and endure the desert landscape of Mars. A material with such properties already exists, rubber. Wheels on earth are made of inflated rubber because they can absorb the impacts of uneven terrain without any consequences. Unfortunately, using rubber wheels on Mars is not feasible since the surface of this planet can get down to temperatures of -130 degrees ° C/ -202 °F [8]. At very low temperatures (below -50 degrees C/ -58 °F), rubber loses its elasticity and becomes brittle. Bending or stretching the material at such low temperatures will produce glass-like shattering, which makes rubber unsuitable for wheels on Mars [9].

A different approach will be needed, and this is why engineers and scientists at the NASA Glenn research center started investigating the applicability of so-called “spring tires” for Mars missions. Spring tires are airless tires made of hundreds of steel wires woven together in a mesh, providing a high load-bearing capacity while retaining some elasticity. This technology has been used in space exploration missions, specifically on the lunar surface. Nevertheless, due to the increased gravity of Mars compared to that of the moon, the elasticity provided by these wheels would not be enough to carry a big rover like Curiosity around Mars. This is because any significant additional stress on the wheels, like sharp rocks or falls, could bend the wires that make up the wheel which would cause permanent deformation and loss of function [3].

Figure 3: Steel spring tires [3]

Revamping old technology with newer materials:

To overcome the problem of elasticity that spring tires had, scientists at the NASA Glenn Research Center came up with the idea of replacing the steel wires with another, more innovative, material. This material is called nitinol [3].

Nitinol is a nickel, and titanium alloy discovered at the Naval Ordnance Laboratory. This is where the name of the alloy comes from; Nickel-Titanium Naval Ordnance Laboratory nitinol [10]. Nitinol has two unique properties that make its application to new technologies exciting.

Elasticity is the property that a material has to be bent or stretched by a force and still be able to return to its original state. When most materials are stretched, the atomic bonds forming them stretch until they break off one another. The material starts to show cracks; this is a point of no return since the atomic bonds holding the material in its previous state no longer exist. This point of no return is also known as reaching plastic elasticity [11]. The magnitude of the force that caused this permanent deformation is known as the yield strength of the material (i.e., how much stress a material can take before permanently bending) [12]. Nitinol is superelastic because when it is under stress, its atomic bonds do not break off; they simply rearrange themselves. Exploring the differences in aluminum and nitinol properties can help us understand this concept. Nitinol is much easier to bend than aluminum as it only requires a force of 100MPa (megapascals) compared to 276 MPa required to bend aluminum. The difference, however, is that beyond this point, Aluminum cannot return to its original form because it has reached plastic elasticity; it will stay bent. Nitinol, on the other hand, will return to its original form. If we keep increasing the stress on the materials, Aluminum will be the first to completely fail and break at 310MPa, while nitinol can withstand up to 960MPa before breaking. Nitinol is superelastic because it never reaches plastic deformation until its breaking point. If the force applied is below 960MPa when released from stress, nitinol will become unbent again [13][14].

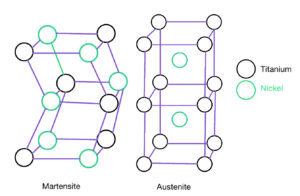

The atoms of nitinol are arranged in a particular crystal structure that allows its unique properties. At high temperatures, nitinol retains a crystalline structure called austenite; in this atom configuration, nitinol achieves its maximum stiffness and has a higher elasticity. When cooled down, nitinol forms a martensite structure that can more easily be distorted [15]. The important part is that when energy is introduced into nitinol in its martensite structure, be it through heat or stress, nitinol will revert to its original shape in its austenite configuration [16]. Effectively remembering its past shape, this property is called shape memory. Instead of breaking under stress or stretching, nitinol atoms shift from one atom configuration to another. Both atom configurations of nitinol can be seen below in [Fig 4].

Figure 4: Austenite and Martensite configurations of nitinol

Using the two unique properties of nitinol, NASA scientists created a wheel prototype that surpassed its predecessors in many categories.

Benefits of nitinol wheel for space exploration:

The superelasticity of nitinol allows for wheels that can deform in ways previously thought impossible. The prototype made by NASA engineers could deform from the outer edge of the tire to the axle in the middle of the tire [3]. By deforming in this way, the tire material experiences energy in the form of stress. Then the nitinol threads utilize this energy to return to their original shape (shape memory by atomic rearrangement) [3].

The ability of nitinol wheels to deform without permanently losing their original structure has vast implications for future space exploration missions. One of the engineers’ priorities when building rovers for planetary exploration is ensuring their longevity. The reasoning is that sending and operating a robot on Mars is incredibly expensive. The cost of the Curiosity rover was over 2.5 billion dollars [17]. If any one component of the rover fails, the entirety of the mission fails. That is why having wheels so impervious to damage is such a significant improvement for future missions. If one component can be made foolproof, it is one less thing that could risk the entire mission.

Besides being more robust, the nitinol “superelastic tire” has a higher load-bearing capability [18]. This capability will allow future missions to bring more scientific equipment without hurting the rover’s performance. Additionally, the higher load-bearing capability and the wheels’ durability allow for higher travel velocities without possible damage to the robot or the wheels.

Looking towards the future:

The Mars rovers are only the beginning of our adventures on other planets. Eventually, humans will want to travel there themselves and they’ll need better transportation methods which nitinol wheels could be a part of.

A man-operated vehicle will have to have a high load-bearing capacity to carry all the survival and scientific equipment needed and the passenger or passengers. Additionally, it is reasonable to think a human-operated vehicle will have to have a higher velocity than that of our current robots. The top speed of the Curiosity rover on flat terrain is 0.8 kilometers per hour which are far too slow for human-operated missions [5]. Finally, a human-piloted vehicle on other planets must be as reliable as possible. A vehicle breakdown in a Martian sandstorm sounds like a terrible nightmare.

Interestingly, all three requirements that man-operated vehicles on other planets will have to meet could be fulfilled using nitinol wheels.

Nitinol for our everyday life:

The applications of nitinol are not limited to space exploration. Research in the military and space industries lead to the development of great innovations for our day-to-day life. GPS, the microwave oven, and the internet were all caused by this “trickle-down” of innovations, and nitinol could be no different.

The engineers and scientists behind the “superelastic” nitinol wheel argue that this technology could one day be used on earth. These tires are airless and virtually impossible to damage. Additionally, nitinol wheels are made of just one piece, making them lighter than standard air-filled wheels and easier to assemble [18].

Another interesting aspect of nitinol is that the temperature necessary for switching between atomic configurations can be regulated by adjusting its Titanium concentration. This property opens the door for many daily applications for nitinol. The most common of these is in the medical field. Suppose one sets the temperature necessary for transforming nitinol to 37 degrees C ( the average human body temperature). In that case, one could fashion a device that could change its shape when it comes into contact with the human body. This is already being used to fabricate stents made out of nitinol. Stents are tube-like structures used to amplify or fortify the veins/arteries of a patient, preventing clogged arteries and veins, a common cause of heart attacks [19]. Implementing traditional stents can harm the human body by requiring a complicated mechanical process of inserting tubes into the patient’s cardiovascular system.

In contrast, a stent made of nitinol could be inserted without much effort. Before implementation, it retains the shape of a thread. However, once the nitinol contacts the patient’s tissue, it expands into a helix shape, achieving the same results as standard stents without complications.

Nitinol perfectly exemplifies why we should be excited about technology and engineering innovations. It can help us discover and learn more about the mystery of the universe by being a core innovation on a robot on another planet millions of miles away, and humans might also be able to see it soon here on earth. Nitinol-based glasses frames which don’t break or bend when you sit on them or some other imaginative application of the material could help people in their daily lives. That is what engineering innovation is all about, helping to answer the biggest and most daunting enigmas of life and making our ordinary lives just a little better whenever possible.

Nitinol has a bright future in the scientific community and our daily lives. Thanks to its unique properties, it will undoubtedly see varied applications throughout our society.

Keyword list:

Nitinol, space exploration, innovation, shape memory, super elasticity, Mars, Mars rover, Curiosity Rover, Wheels.

References:

[1] D. Ansari, “What does sol mean on Mars, and how long is it compared to a day on Earth?” Republic World, 29-Jul-2020. [Online]. Available: https://www.republicworld.com/technology-news/science/what-does-sol-mean-on-mars.html. [Accessed: 02-Sep-2022].

[2] “Mission Monday: 5 fast facts about NASA’s Curiosity rover,” Space Center Houston, 12-Oct-2020. [Online]. Available: https://spacecenter.org/mission-monday-ahead-of-anniversary-five-fast-facts-about-nasas-curiosity-rover/#:~:text=It%20has%20been%20on%20the,much%20more%20about%20the%20planet. [Accessed: 02-Sep-2022].

[3] N. Smith Kilkenny, “Reinventing the wheel,” NASA, 26-Oct-2017. [Online]. Available: https://www.nasa.gov/specials/wheels/. [Accessed: 02-Sep-2022].

[4] “Mars Science Laboratory curiosity rover – mars missions – NASA Jet Propulsion Laboratory,” NASA. [Online]. Available: https://www.jpl.nasa.gov/missions/mars-science-laboratory-curiosity-rover-msl. [Accessed: 12-Dec-2022].

[5]“Wheels,” NASA, 20-Aug-2019. [Online]. Available: https://mars.nasa.gov/msl/spacecraft/rover/wheels/. [Accessed: 02-Sep-2022].

[6] M. Cutolo, “This is why all credit cards are the same size,” Reader’s Digest, 11-May-2022. [Online]. Available: https://www.rd.com/article/credit-cards-size/. [Accessed: 02-Sep-2022].

[7] The Spaceflight Group Website and Name, “Curiosity wheel issues and solutions: A conversation with JPL’s Jim Erickson,” Space Safety Magazine, 02-Sep-2014. [Online]. Available: http://www.spacesafetymagazine.com/space-exploration/curiosity/curiosity-wheel-issues-solution-conversation-plus-Jim-Ericksonn/. [Accessed: 02-Sep-2022].

[8] T. Sharp and J. Gordon, “What is the temperature on Mars?,” Space.com, 31-Jan-2022. [Online]. Available: https://www.space.com/16907-what-is-the-temperature-of-mars.html. [Accessed: 02-Sep-2022].

[8] “Properties of rubber at low temperatures,” Nature News. [Online]. Available: https://www.nature.com/articles/149645a0#cites. [Accessed: 02-Sep-2022].

[10] About Nitinol, 22-Oct-2018. [Online]. Available: https://www.saesgetters.com/products/about-nitinol#:~:text=Nitinol%20is%20a%20trade%20name,tools%20for%20dismantling%20magnetic%20mines. [Accessed: 02-Sep-2022].

[11] “Elasticity,” Encyclopædia Britannica. [Online]. Available: https://www.britannica.com/science/elasticity-physics. [Accessed: 02-Sep-2022].

[12]“Yield strength – strength ( mechanics ) of materials,” YIELD STRENGTH. [Online]. Available: https://www.engineersedge.com/material_science/yield_strength.htm. [Accessed: 02-Sep-2022].

[13] “The Online Materials Information Resource- Nitinol,” MatWeb, 09-Dec-2022. [Online]. Available: https://www.matweb.com/search/DataSheet.aspx?MatGUID=44afc7d3c6eb4829bc2df27884fd2d6c&ckck=1. [Accessed: 09-Dec-2022].

[14] “Aluminum,” ASM material data sheet, 09-Dec-2022. [Online]. Available: https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=ma6061t6. [Accessed: 09-Dec-2022].

[15] “Everything you need to know about nitinol – product development guide,” Synectic Product Development, 23-Jun-2022. [Online]. Available: https://synectic.net/everything-you-need-to-know-about-nitinol/#:~:text=The%20metal%20enters%20the%20Martensite,and%20recovers%20its%20previous%20shape. [Accessed: 02-Sep-2022].

[16] C. H. Fu, M. P. Sealy, Y. B. Guo, and X. T. Wei, “Austenite–martensite phase transformation of biomedical nitinol by Ball Burnishing,” Journal of Materials Processing Technology, 28-Jul-2014. [Online]. Available: https://www.sciencedirect.com/science/article/pii/S0924013614002787?casa_token=H4doNNwkEf8AAAAA%3A2VSKZAyydqLfhYI7zyHoF77P6-5Pgx13DojB_83u-VnOyRfrKlZ9IU5wgFKFrC_3GbkHkYs2sw0#fig0005. [Accessed: 02-Sep-2022].

[17] J. Folger, “Why curiosity cost $2.5 billion,” Investopedia, 21-Feb-2022. [Online]. Available: https://www.investopedia.com/financial-edge/0912/why-curiosity-cost-2.5-billion.aspx. [Accessed: 02-Sep-2022].

[18] “Superelastic tire,” NASA. [Online]. Available: https://technology.nasa.gov/patent/LEW-TOPS-99. [Accessed: 03-Sep-2022].

[19] “Coronary artery disease,” Mayo Clinic, 25-May-2022. [Online]. Available: https://www.mayoclinic.org/diseases-conditions/coronary-artery-disease/symptoms-causes/syc-20350613. [Accessed: 19-Sep-2022].