Getting enough water is one of the greatest challenges in human spaceflight. As its mission objectives have become increasingly more ambitious, NASA has been at the forefront of water purification technology. Designers of water purification systems for space travel face many of the same challenges as designers of systems for use in developing nations, and many of the purification systems developed by NASA have been adapted for use here on Earth. Water purification technology from the Apollo lunar missions has been successfully commercialized, and a system based on the Space Shuttle’s water purifier is widely in use in developing nations today. Currently, NASA is developing even more advanced water purification systems for use on the International Space Station and future outposts on the Moon and Mars. While this most recent technology is more advanced than necessary for most current applications, it may still eventually contribute to making people’s everyday lives better right here on Earth.

Introduction

What has NASA done for you lately? While the name of the U.S. space agency may evoke images of rockets soaring out of the atmosphere on pillars of flame (see Fig. 1), many technologies developed for the space program have been adapted for everyday use here on Earth. NASA calls these commercialized technologies “spinoffs,” and there are thousands of them affecting our lives today, improving everything from medicine to computer technology . The classic example that comes to mind for most people is the orange-flavored breakfast drink Tang, although it is not a true spinoff. Tang was actually developed before human spaceflight began, but it did gain popularity after NASA used it on the Gemini missions [1]. For people in disaster areas or developing nations, though, NASA spinoffs can mean improved access to a far more essential drink: pure water. Technology developed by NASA to provide clean water to astronauts on long-duration space missions is being adapted and implemented for better water purification on Earth.

The Need for Water Purification

Getting enough water is one of the greatest challenges in human spaceflight. Human beings cannot survive without water, but water is heavy and it occupies a large storage volume. In the early days of human spaceflight, when missions lasted only a few hours or at most several days, it was possible to launch space travelers from Earth with all of the water they needed. However, as mission plans lengthened, bringing water from Earth to sustain human life for extended periods became less feasible. Instead, researchers began to develop water purification technology to recycle the limited water supply that could be provided.

While astronauts face challenges in getting enough water to survive in space, many more people have the same problem in developing nations down here on Earth. According to the World Health Organization, 1.1 billion people, or 17% of the global population, lacked access to a safe water source in 2002. Interestingly, designers of water purification systems for space travel face many of the same challenges as designers of systems for use in developing nations. The key features of equipment suitable for both settings are durability, simple design, and low maintenance requirements. Obtaining specialized parts or personnel experienced in water system repair can be equally difficult in space and in developing nations. Given these similarities, water purification technology designed for NASA can be very useful to developing nations if the right adaptations are made to it [12].

Proven NASA Water Technology

NASA began developing spacecraft water purification systems for the Gemini program in the 1960s to back up water supplies brought from Earth [2]. Its first successful spinoffs in this area came from Apollo-era technology, though. For the lunar missions, NASA developed a lightweight water purifier the size of a cigarette pack that was designed for minimal power consumption and monitoring. Later, a private company obtained NASA’s permission to modify the purifier for commercial and industrial use. The commercial system passes a small electrical current through copper and silver electrodes, releasing ions into the water being purified. The ions kill bacteria and algae in the water by breaking down their enzymes, and the ions and dead organisms are then filtered out of the water. This is similar to the way that chlorine is used in swimming pools, but metallic ions are more stable and less irritating to the human body than chlorine ions. This water purification system is now used in swimming pools, fountains, and cooling towers [3].

Commercial technology geared more toward drinking water purification came from NASA’s Space Shuttle program. The Apollo spacecraft were designed for one trip, but the Space Shuttle is reusable, so it requires a longer-lasting water purification system. In the Space Shuttle, water is passed through a bed of tiny resin beads containing iodine; this process introduces iodine ions into the water supply that work in the same way as chlorine or metallic ions. The resin bed does become depleted over time, so to lengthen the interval between replacements, the bed is recharged with iodine by periodically flowing the water over iodine crystals before passing it through the resin beads [4]. This technology has been successfully adapted into commercial units that purify approximately 5 gallons (about 20 liters) of water per minute. Because the units do not require electricity, they are ideal for developing countries or emergency situations after natural disasters, when power might not be available [5].

Global Development for Community Drinking Water

Commercialized purifiers using NASA’s Space Shuttle technology have been successfully implemented worldwide. In 1994, for example, the prime minister of Vietnam endorsed an order for 10,000 of these iodine-based purification units [4]; this was estimated to provide clean water to 50 to 70 million people [5]. In 1998, the company that originally adapted the NASA technology reported over $10 million in sales of these purifiers since their introduction [6]. Other companies have continued to improve the technology; in 2006, a non-profit organization called Concern for Kids purchased an upgraded purification unit and installed it in the village of Kendala, Iraq (see Fig. 2) with the help of NASA engineers who were designing the next generation of water purification systems for space travel[7].

Current Developments

Although astronauts sometimes spend weeks in orbit aboard the Space Shuttle (see Fig. 3), they can still carry all the water they need with them from Earth. In contrast, on the International Space Station (ISS), which continuously harbors a human crew, the demand for water is much greater. Although a Russian-built device currently recycles some water on the ISS by condensing humidity from the air, about 580 gallons (2200 liters) of water must still be brought up from Earth to support a crew of three each year, at a cost of about $24 million [8]. Taking water farther from Earth would be even more expensive, creating a tremendous roadblock to establishing the permanent bases on the Moon or Mars that are central to NASA’s plan for meeting President Bush’s 2004 “Vision for U.S. Space Exploration” [9]. Currently, the most viable option is to launch with a limited water supply and recycle nearly all of it to minimize the cost of refilling. To this end, there are several projects underway at NASA to develop improved water purification systems for the ISS and future space settlements.

Engineers are putting the finishing touches on a water purification system that will recycle 93 percent of the water used on the ISS. The most intense processing will be applied to astronauts’ urine. When astronauts flush the space toilet, 10 fluid ounces (0.3 liters) of water will be added to every 40 fluid ounces (1.2 liters) of urine, along with some chromium dioxide and sulfuric acid to kill microbes and stop the chemical reactions that cause odors. This mixture will then be pumped into a distillation cylinder, which spins to pull the liquid into a thin film on the walls and prevent it from floating around in the station’s microgravity. The distiller will heat the mixture so that pure water boils off, leaving behind concentrated “brine.” To reduce the power required for heating, the distiller will be kept at low pressure, so the water will evaporate at a lower temperature. This phenomenon is familiar to anyone who has adjusted recipes for cooking in the mountains; atmospheric pressure decreases as altitude increases, so water boils at a lower temperature when at altitudes higher than sea level. On the ISS, the distiller will be kept at barely 5% of sea level atmospheric pressure, so the water in it will evaporate at about 105 degrees Fahrenheit (40 degrees Celsius). A compressor will then condense the water vapor back into liquid form on the outside of the cylinder; the condensation process releases heat, which will travel back through the cylinder walls to help reheat the brine. The process will be repeated until 85 % of the water is recovered from the urine, at which point the remaining brine will be transferred to storage containers, later to be jettisoned to burn up in Earth’s atmosphere (Muir 48-49).

Water distilled from urine will be mixed with waste water from other sources, like washing and tooth brushing, for further purification. First, the water will be filtered to remove particulates. Next, it will flow through activated carbon beds to remove inert organic compounds like benzene as well as ion-exchange resin beds to remove salts. Then, to remove volatile organic compounds like ethanol and acetone, the water will be run through a catalytic oxidizer. This piece of equipment will heat the water to 275 degrees Fahrenheit (130 degrees Celsius) and inject it with oxygen gas. The heat will kill any remaining microorganisms, while the oxidization will convert the volatile organic compounds to carbon dioxide or more stable organic acids. These residuals can then be removed with passes through further ion-exchange beds. Finally, the water will be clean enough to drink; it will be stored with a little iodine to prevent microbe growth. This purification system will be able to produce about 1.5 gallons (6 liters) of drinking water per hour, and astronauts will probably run it 8 to 10 hours every other day to meet their water needs. It is slated to be installed on the ISS in October 2008 [8].

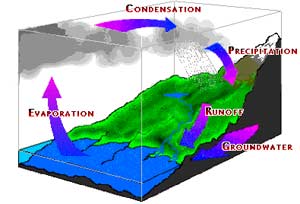

On board the ISS, the primary concern for all systems is low power consumption. As a result, the water purification system that is about to be installed has been designed to remove most impurities with filters, minimizing the amount of energy expended to heat the water. Although the filters become depleted over time, they can be replaced with new ones from Earth on a fairly regular basis. The situation at permanent outposts on the Moon or Mars, however, will be reversed; resupply missions will be infrequent, but more power will be available. With this in mind, engineers are designing a water purification system that relies more heavily on heating than the use of filters. Michael Flynn, principal investigator for the project, says that the system mirrors the natural hydrologic cycle (see Fig. 4):

“The sun heats the water [in Earth’s oceans], which evaporates and forms clouds. Those clouds are exposed to ultraviolet radiation, which destroys organic contaminants, and then rain falls to begin the cycle again. We’ve integrated all of these processes into a single small machine. We take in waste water, vaporize it, oxidize organic contaminants, re-condense it, and the water is ready for use” [10].

Like the ISS system, the water purifier designed for the Moon and Mars includes a catalytic oxidizer. However, before the water reaches the oxidizer, it is heated to high temperatures in an evaporator rather than passing through filters; the evaporator uses more power but has fewer disposable parts. This purifier requires 300 watt hours of electrical power per kilogram of water produced, and it can work for up to three years without replacing any parts. By contrast, the ISS purifier only uses 123 watt hours per kilogram, but it requires new filters every 60 to 90 days [10]. NASA has explored both sides of this design trade-off to meet its water needs.

Potential for Future Commercialization

The water purification technology currently under development at NASA has uncertain prospects for commercialization. Concern for Kids, the organization that brought Space Shuttle purification technology to Iraq, has already expressed interest in purchasing 22 units based on the ISS purifier [11]. However, the level of purification the ISS system can provide is actually higher than necessary for drinking water, and program manager Dave Parker admits, “While you could plug this system into a municipal water system, I suspect that the economics wouldn’t work” [10]. At this point, older water purification technologies are more cost-effective, especially for developing nations.

But the new systems NASA is developing may eventually see use in naval vessels, hospitals in remote locations, or other situations in which very pure water is needed but the local supply is highly contaminated [10]. Furthermore, even if the systems as a whole are not widely implemented, individual components or even lessons learned in developing them may be useful. NASA’s work in water purification has shown that technology developed for the space program can be applied far beyond its original purpose. NASA doesn’t just lift people off this planet; it helps improve everyday life on it.