Introduction

Imagine taking off from the airport and flying across the world in one or two hours instead of twenty. This goal has inspired some of the most tantalizing innovations in the modern age. The thrill of seeing a fighter jet take off and zoom across the sky, disappearing over the horizon in a matter of seconds followed by a thundering sonic boom is not an experience soon forgotten. Still, for others the sight may invoke fear, as the thought occurs that the purpose of these vehicles is not always friendly. The mechanics of crossing the sound barrier into supersonic flight, and then surpassing five times the speed of sound into hypersonic flight are mind-bending but getting to know about these impressive machines can help build an appreciation for the industry, and the feats of engineering that helped will them into existence. This article will help give an insight into these mechanics by comparing what we know about subsonic flight and how supersonic flight is different, as well as some of the special challenges that need to be overcome to achieve these speeds. Finally, we will see what innovations will come next and how they will impact our lives.

Fig. 1 Counterclockwise from left to right: X-31, F-15, SR-71 Blackbird, F-106, F-16XL, X-38. In the middle: X-36, Radio Controlled Mothership.

Source: Adapted from [4]

Subsonic vs. Supersonic Mechanics

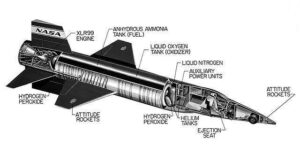

Before we talk about supersonic flight, there are some things that are important to understand about subsonic flight. Passenger jets typically have a “tube and wing” design, with a long passenger section, large wings that carry the engines and fuel, and a tail section that offers passive flight stability which may include additional jet engines and fuel [1]. This design scheme is significantly different from supersonic aircrafts, such as the X-15. This jet features a main body fuselage entirely composed of a massive engine and fuel tanks, with a small cockpit for the pilot at the front; a diagram of this is shown in figure 2. Many aircrafts have been designed that are capable of surpassing the sound barrier, some of which can be seen in Figure 1. However, the Bell model was one of the first successful designs that broke the speed barrier.

Fig. 2 X-15 interior design scheme

Source: Adapted from [5]

A striking difference between subsonic and supersonic flight models is the wing area and orientation. In order to achieve stable takeoff and landing, a passenger aircraft’s wings need to provide enough lift so that it can operate at lower speeds. This requires a fine balance between its frontal wing area and sweep angle. The backwards swept wing angle provides this lift while minimizing the frontal surface area. Keeping this area minimized helps reduce drag, and increases both the engine efficiency, and maximum cruising speed [1]. As the aircraft reaches higher speeds, the wings produce more lift and thus require less frontal surface area to maintain flight and control, but, as the speed increases, so does drag, which takes a toll on fuel efficiency. This is why we see slower moving aircraft with more of a perpendicular wing angle, such as with typical propeller driven aircraft, and supersonic jets with a much more acute wing angle.

Airliner jets have a backwards swept angle that’s carefully designed to allow for efficient operation just below the speed of sound, also known as Mach 1. They travel efficiently at speeds of around 500-650 miles per hour, which translates to about Mach 0.80 to 0.88, meaning 80 to 88 percent the speed of sound. This sweep angle lowers the drag at cruising altitude and speed, but requires more energy to take off, as well as increasing the aircraft’s critical Mach number, which is the speed at which supersonic air flow first appears around the wing. This happens before the plane itself achieves supersonic speeds, since air speeds up as it travels across the wings upper surface. This effect is called transonic airflow, and it interferes with control surfaces while drastically increasing drag, as the pressure differentials around the wing become severe and erratic. This is why typical airliners cruise just below this critical Mach number and can’t travel any faster.

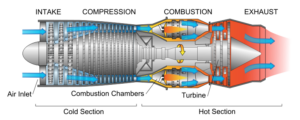

Fig. 3 Basic design structure of a turbojet.

Source: Adapted from [6]

The engines that propel passenger jets, and supersonic aircraft share many similarities. They use air-breathing engines, meaning they take in atmospheric gasses and use them in the combustion process and expel the ignited mixture through a nozzle to produce thrust. These massive engines are a marvel of engineering design, and represent countless hours of research, design, and experimental tests. An example of this is the turbojet engine, (pictured in Figure 3), and there are many variations of these found in commercial airliners and military jets. They are made up of six main components which can be seen in figure 3: The high-bypass intake turbine, compressor, combustor, low-bypass turbine, mixer, and a nozzle [2]. The first component is the high-bass turbine, featuring a large fan which sucks in vast quantities of air at the intake, which then flows around the engine core to help cool the hot end. The compressor takes some of this air and uses several stages of turbines to compress the air from the intake. Next, this compressed air flows through the combustion chamber, which houses an array of fuel injection nozzles that saturates the airstream. This process creates ideal conditions for ignition, which occurs within the combustion chamber. Once combustion occurs, the high temperature mixture expands and is accelerated through the low-bypass turbine, causing the blades to spin up to extreme speeds. The accelerated air then flows through the mixer, which combines the high temperature air from the engine core with the colder air from the high-bypass turbine, which helps make the engine quieter, and more efficient, while at the same time adding thrust. The final component is the nozzle, which funnels the air mixture into a smaller space, increasing the pressure, then expands at the end to let the air escape at higher speeds, thus producing thrust.

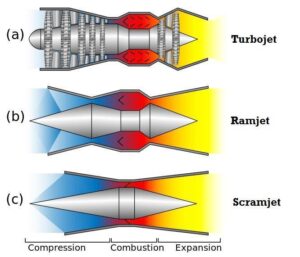

Fig. 4 Comparison of Turbojet, Ramjet and Scramjet designs

Source: Adapted from [7]

One major difference between supersonic and subsonic engine design comes from a phenomenon that occurs at supersonic speeds. After the aircraft crosses the sound barrier, air becomes compressed by the shockwaves produced around a cone called the aerospike, which is situated at the intake of the engines [1]. This is the idea behind ramjet engines, which also use shock cones to decelerate the air to subsonic speeds before combustion. Another type of engine called the supersonic combustion ramjet, or scramjet, doesn’t use a shock cone. Instead, the scramjet slows the airflow intake by shockwaves produced within its ignition chamber. Another key difference you may notice between these engines is that the ramjet and scramjet use no rotating parts (figure 4). These mechanics allow the designs of ramjet and scramjet engines to be comparatively much simpler, however, the drawback is that they don’t become efficient for flight until about Mach 2, and around Mach 3 for scramjet engines. This means that different launch techniques were required for these aircraft to work properly. Similar to how the first aircrafts broke the sound barrier, the Bell X1, or the X-15, these aircrafts were typically drop-launched from a B-52 which was traveling at maximum speed.

Apart from engine mechanics, there are also key differences in the aircraft’s outer aerodynamic design. The transonic Area Rule is an important rule that supersonic aircraft must follow to help ensure stability at higher Mach numbers. This rule states that the cross-sectional area must be smoothly distributed across the body of the aircraft in a steady bell curve, meaning most of the mass is situated in the center of the vehicle, and evenly tapers off towards each end [2]. Aircraft that follow this rule break with the typical tube-and-wing design, and feature wing geometry with a backwards swept angle that blends smoothly into the body, giving them a distinct aesthetic. A good example of this is the SR-71 Blackbird, pictured below in figure 5.

Fig. 5 SR-71 Blackbird

Source: Adapted from [8]

Engineering Challenges

We know that the wing and engine designs can help these aircraft overcome the extreme conditions while soaring through the atmosphere at hypersonic speeds, but these are just a few of the challenges that need to be overcome to make these impressive machines work. For example, selecting appropriate materials that can withstand extreme conditions, choosing the right type of fuel, and ensuring that the engines can operate effectively without overheating all add to the engineering design challenge. Specialized fuel injectors need to supply the combustion chamber with fuel fast enough to keep up with the engine’s consumption; around 5000 kilograms of fuel per minute [2]. These pumps are also responsible for regenerative cooling, where the chilled fuel, which is stored in cryogenic tanks, is pumped around the engine’s hot end to help cool the surfaces while simultaneously heating the fuel to a temperature more easily combustible in the engine.

This is why fuel choice and formulation are important challenges. There have been tests where the kerosene used for fuel would polymerize around impurities and clog up these chambers, leading to catastrophic overheating in the engine. Popular rocket propellent fuels such as hydrazine were also tested, which was found to spontaneously combust at temperatures low enough to ignite inside the regenerative cooling ducts. Other major problems are encountered due to thermal expansion. Thermodynamic heating does not scale linearly with speed since the drag of an aircraft increases with the square of its velocity. The friction due to interactions with air molecules and the pressure differentials around the aircraft transmit heat to the surfaces. The thermal expansion due to this heating is not only extreme but happens unevenly across the plane’s surface. To compensate for this, engineers must anticipate the materials expansion, and in some cases leave gaps in the structure, as in the case of the SR-71. The gaps in the structure were large enough that fuel leakage was common and could be seen dripping down in substantial quantities on the runway. This was an acceptable problem at the time since the fuel was relatively inert.

Considering all of these challenges, and many others, the biggest challenge for engineers comes down to keeping the engines running at these insane speeds. The problem of maintaining stable combustion in supersonic and hypersonic jet engines is analogous to lighting a match in a hurricane. Maintaining stable supersonic combustion in the scramjet is essential in order to produce continuous and sufficient thrust to overcome all drag forces. The failure of maintaining stable combustion has been termed “unstart” and continues to represent an important technical barrier in the development of scramjets. Unstart refers to a phenomenon in which the internal system of shocks inside the engine is unexpectedly expelled outside the engine in a short amount of time, preventing prompt corrective action on control surfaces or engine power and that can eventually cause loss of aircraft control. In scramjets, a full unstart causes the flow in the entire engine to become subsonic. As a result, the dynamic compression of the airflow occurs solely through external shock waves that create a large spillage of air around the inlet and a large increase in drag [2].

The good news is that needing specially designed hypersonic wind tunnels is no longer the only way to test equipment. Using sophisticated computer aided simulations and analysis programs have allowed engineers to test designs before spending millions to manufacture them. With these programs, the innovations needed to make supersonic air travel sustainable, efficient, and economical is much more accessible. The use of additive manufacturing methods like 3D printing, and AI generated models also opens the doors to better solutions such as fuel injectors, where in the past we have had to rely on metallurgists and entire construction teams. New modeling software has been developed such as Ansys which offers generic multidisciplinary analysis (MDA) and optimization frameworks for aeronautical products [3]. These systems have and will continue to play a crucial role in designing the next generation of transonic aircraft.

The Importance of Supersonic Travel & Next Steps

So, what can we hope to see in the near future for supersonic aircrafts? It is now agreed that small-size supersonic transport aircraft is likely to be the next supersonic aircraft on the market [3]. This means that passenger jets may not accommodate supersonic speeds for several years, as engineers continue to work out ways to increase the flight efficiency and reduce fuel consumption to a point where the flights are affordable. The sonic boom created by supersonic aircraft is a larger concern than just noise; there were reports of structural damages to buildings during tests, as the compression waves that reached the ground were strong enough to break glass [2]. The US actually used to fly the SR-71 Blackbird over Soviet and Nazi territory during important public addresses just to bother them.

Access to high-fidelity modeling and analysis software allows issues such as fuel economy and even sonic boom mitigation are now being addressed much more rapidly. There are several designs that are already in production that we will see hit the market by the end of 2023, such as the Hermeus Moonshot program which is in production on an aircraft called “Quarterhorse”, will be capable of taking off and landing from the ground, and can cruise speeds exceeding Mach 5. Weaponized applications also rely on the fact that aircraft can travel faster than defense systems’ detection. For example, the SR-71 was successful because it was able to travel fast enough so that missiles never caught up to them. Today we have a different issue, that is, missiles that travel so fast that nothing can stop them, as these engines are not merely limited to planes. However, as more companies are competing to produce the next generation of aircraft, the focus is shifting more towards passenger travel.

What we know about these mechanics, and the innovations which allow us to better solve the challenges surrounding hypersonic travel is bringing us ever closer to making these vehicles a reality. The innovations we can hope to see in the future are sure to be awe inspiring. After all, as Cave Johnson said: “Science isn’t about ‘why’, it’s about ‘why not!’.”

References

- E. Torenbeek, Essentials of supersonic commercial aircraft conceptual design, First edition. Hoboken, NJ: John Wiley & Sons, Inc., 2020.

- J. Urzay, “Supersonic Combustion in Air-Breathing Propulsion Systems for Hypersonic Flight,” in Annual Review of Fluid Mechanics, Annual Reviews, 2018.

- Joel Brezillon, et al. “Multidisciplinary Optimization of Supersonic Aircraft including Low-Boom Considerations,” in Journal of Mechanical Design, ASME, 2011.

- NASA. Research Aircraft Fleet. (16 July 1997). Accessed: Feb 07, 2023. Available: https://commons.wikimedia.org/wiki/File:EC97-44165-149.jpg

- NASA. X-15 RCS Rockets. (Dec 30, 2009). Accessed: Feb 07, 2023. Available: https://commons.wikimedia.org/wiki/File:X-15_RCS_rockets.jpg

- Jeff Dahl. Jet engine. (Dec 16, 2007). Accessed: Feb 07, 2023. Available: https://commons.wikimedia.org/wiki/File:Jet_engine.svg

- Grey Trafalgar.Turbo Ram Scramjet Comparative Diagram. (July 2, 2010). Accessed: Feb 07, 2023. Available: https://commons.wikimedia.org/wiki/File:Turbo_ram_scramjet_comparative_diagram.svg

- US Air Force. Blackbird soars above northern California. (June 1, 1988). Accessed: Feb 07, 2023. Available: https://commons.wikimedia.org/wiki/File:SR-71_Blackbird_soars_above_northern_California.jpg