Abstract

Wood has played a central role in construction for centuries, offering strength, durability, and a natural aesthetic. However, while it has been primarily a structural material, a new approach could revolutionize the ways wood can be used. Transparent wood is a new variation formed by chemically removing the darker color component called lignin. The removal of only lignin allows transparent wood to retain most of the wood’s strength and durability with the added benefit of light transparency. Transparent wood’s inherent physical properties make it a compelling candidate to replace glass as a stronger and more thermal-insulating transparent material. As architects and builders seek eco-friendly solutions, the integration of transparent wood into buildings opens new avenues for energy-efficient designs and visually captivating structures, ushering in a new era in construction technology.

Introduction

Wood as a building material has been used since the time of our earliest ancestors. Some advantages of wood that have made it a favorable construction material over the years include its natural abundance and renewability, as well as its strength, durability, and insulating properties. One recent innovation to this material is transparent wood, which retains the traditional benefits of wood along with the new advantage of being see-through. While the construction process of transparent wood is still being researched and optimized, by understanding the science behind the material and the manufacturing steps, we can better understand its potential and future applications.

The Concept

The idea to strip wood’s natural brown color and make it transparent started with German botanist Siegfried Fink in 1992. Fink’s motivation for exploring transparent wood was to gain a clearer view of the internal structure of wood [1]. Transparency can be defined as the extent to which an object allows light to pass through it. A non-transparent object such as traditional wood does not let light pass through it, as the light is mostly absorbed or scattered. The absorption and scattering of light gives wood its brown color [2, 3].

Wood is composed of cellulose, hemicellulose, and lignin [4]. While all three are important to the structure of wood, lignin is responsible for its brown coloration. Removing lignin solves the light absorption problem. The light scattering in the now white-colored wood is due to the difference in refractive index, which measures how much light bends as it enters a material, between the wood cells and the air pockets inside them. By filling these air pockets with a material that has a similar refractive index as the cell walls, the wood will have a uniform refractive index and light will be able to pass through, allowing it to be transparent (see Figure 1 for an example of it being used).

Figure 1: A square piece of transparent wood over a green leaf. [1]

Manufacturing Process

The current manufacturing procedure can be summarized in three major steps: wood selection and processing, lignin removal and decolorization, and inserting a transparent polymer into the air spaces left in the wood. Understanding these processes is crucial for evaluating the feasibility and scalability of transparent wood as a mainstream building material.

1. Extraction and Preparation of Wood

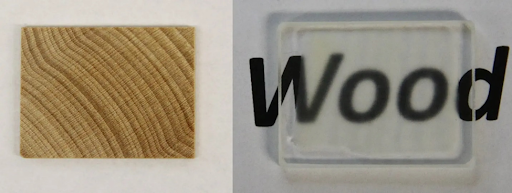

The manufacturing process begins with selecting and extracting suitable wood species. Certain wood species are more conducive to transparency, making the selection process a critical factor in achieving the desired optical and structural properties. Denser wood allows for stronger pieces of transparent wood and better optical clarity. However, denser wood will be heavier, which may be undesirable, as it could introduce logistical challenges if transparent wood becomes a widely used product. The extra weight when transporting both raw and transparent wood would affect its accessibility. After the type of wood is selected, it is cut against the grain, perpendicular to the microscopic tubes that once transported nutrients and water when the wood was part of a tree. Cutting against the grain is key to allow the transparent material added later to be uniformly distributed in the wood [8]. While it is possible to cut the wood along the grain, this orientation creates very long transport tubes, requiring the filler to travel a longer path. With current techniques of embedding this filler into the wood, it would be very challenging to completely fill the wood and achieve consistent transparency. Therefore, all sample pieces created during research are small and thin (see Figure 2 below), to ensure the filler can permeate fully through the wood.

Figure 2: Piece of transparent wood over text that reads “Wood” [7].

2. Chemical Treatments

Chemical treatments play a pivotal role in making wood transparent by removing the lignin that gives wood its color. This process, known as delignification, is essential for achieving the desired level of transparency. Delignification typically involves submerging the wood in a solution that completely breaks down the lignin, stripping the wood of the molecule. While this process removes the wood’s color, it also makes the wood more flexible due to loss of some structural rigidity. Additionally, using such chemicals just to make wood transparent can be environmentally harmful and counterproductive, as it is difficult to dispose or reuse the solution. As a result, another delignification method is to use the sun’s UV radiation to remove the lignin, which results in a less resource-intensive process and a clearer, more light-transmitting product[8]. This process involves brushing a weak acid on the surface of the wood. With assistance from the sun, the color-producing components of lignin are broken down, causing the wood to lose its brown color while maintaining the structural benefits of lignin. The end product of this treatment is milky-white wood, which appears this way due to light scattering between its cell walls and the air pockets left by lignin removal.

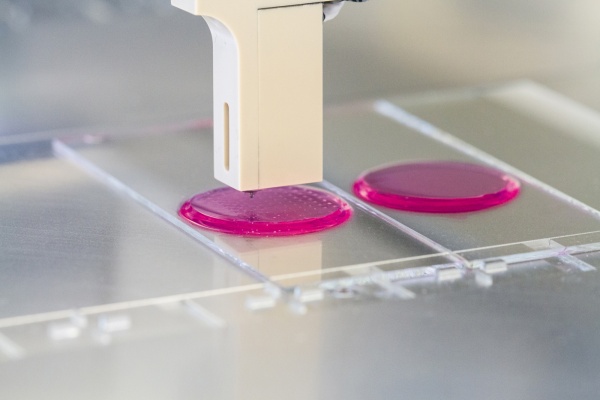

3. Filling the Gaps

After the wood is stripped of its color, it is immersed in a solution of transparent polymers, such as epoxy resin. The polymer solution fills any empty gaps in the wood,including the empty transport tubes and the areas where lignin has been broken down. By filling these empty spaces, the wood achieves a relatively uniform refractive index that allows light to pass through, making it transparent! Before the wood can be used and tested, it should be allowed to rest sothe polymer solution can harden and bond with the structure of the wood.

Applications in Construction

Transparent wood has a range of applications in construction, from windows and facades to interior design elements. Understanding these applications is crucial for architects and builders looking to incorporate this innovative material into their projects. The significance of transparent wood lies in its potential to address key challenges faced by the construction industry, particularly regarding sustainability. As societies worldwide focus on reducing environmental impact and embracing eco-friendly practices, transparent wood emerges as a promising solution.

One of the primary applications of transparent wood is in windows and facades. The material allows for the entry of natural light while providing thermal insulation, contributing to energy efficiency in buildings. In one study, a group created a model house to simulate the impact of using transparent wood windows compared to soda-lime glass, most commonly produced glass. The wooden windows performed just as well as the glass windows in allowing light through and offered superior thermal insulation for the structure. Transparent wood exhibits noteworthy thermal insulation properties, making it a versatile material for construction applications. Unlike traditional transparent materials, such as glass, transparent wood provides a natural barrier to heat transfer. Its unique cellular structure, combined with the absence of lignin and the presence of air-filled lumens, contributes to its thermal insulation capabilities. This property allows transparent wood to regulate temperature effectively, reducing heat loss in colder climates and minimizing heat gain in warmer environments. The material’s ability to control thermal conductivity enhances its energy efficiency, providing a sustainable solution for indoor temperature control. As architects and builders increasingly prioritize energy-efficient designs, transparent wood emerges as a promising choice, offering a harmonious blend of optical transparency and thermal performance.

Environmental Impact

Assessing the environmental impact of building materials is crucial as awareness of sustainability grows. Transparent wood presents an eco-friendly alternative, and a comparative analysis with traditional materials shows its potential to be both versatile and eco-friendly. It surpasses glass in terms of strength, durability, and heat retention. Compared to plastic, transparent wood is more biodegradable, making it better for the environment. Additionally, transparent wood is derived from trees, and planting trees for its production would contribute to carbon sequestration efforts. Transparent wood can also be a more sustainable replacement for glass in applications such as solar panels, as it is low-cost, renewable, and readily available [9, 10].

Challenges and Limitations

While transparent wood holds great promise, it is essential to address the challenges and limitations associated with its use in construction. Despite its high potential, transparent wood is still far from being scalable enough to replace glass or plastic as transparent materials.

The production of transparent wood involves intricate processes and treatments, which may contribute to higher costs compared to traditional materials. Additionally, questions arise regarding the thickness of transparent wood materials since the more cell walls present in the composite, the more likely light will be dispersed, making the material essentially opaque. This translates into more costly chemical treatments to strip away impurities in the material.

Scaling up the production of transparent wood poses challenges related to efficiency, consistency, and volume. To maintain consistent quality in transparent wood, a specific species of wood and an associated chemical treatment process may need to be selected. However, trees do not grow year-round, nor do they grow all across the world (one species that is). This raises logistical challenges to transitioning to transparent wood. Additionally, as mentioned earlier regarding wood selection for manufacturing, wood density and weight would need to be considered when transporting wood before and after manufacturing.

Ensuring the long-term durability of transparent wood structures requires addressing issues such as decay, weathering, and maintenance. Understanding the material’s performance over time is crucial for building resilient and reliable structures, a significant concern not as prevalent with materials like glass and plastic. Additionally, as a wood composite, transparent wood is susceptible to fire. Given the added chemicals and polymers to make it transparent, transparent wood is a notable fire hazard that must be carefully considered, especially if used as a building material. Possible solutions include adding a non-flammable transparent polymer or coating the transparent wood with a flame retardant [11].

The future prospects of transparent wood in construction are promising, with ongoing research and development paving the way for new innovations. “Possibilities include smart windows, wood for heat storage, and wood with a built-in lighting function – even a wooden laser” [12]. With each new discovery about the applications of transparent wood, we can reduce our reliance on costly and fossil-fuel-based materials and move towards a more sustainable future.

Conclusion

Transparent wood represents a groundbreaking development in building materials. Its unique combination of structural strength and optical transparency opens up new possibilities for sustainable and visually appealing architecture. As research continues to enhance its properties and address challenges, the future of transparent wood in construction looks promising. Architects, builders, and researchers can contribute to this transformative journey by embracing and advancing the use of transparent wood in their projects.

Links for Further Reading/Research

- https://knowablemagazine.org/content/article/technology/2023/why-scientists-are-making-transparent-wood

- https://www.optica-opn.org/home/newsroom/2016/august/your_next_windowpane_transparent_wood/

- https://www.youtube.com/watch?v=uUU3jW7Y9Ak

- Video of the transparent wood-making process

References

[1] K. M.-D. 10 Jude Coleman, “Why scientists are making Transparent Wood,” Ars Technica, https://arstechnica.com/science/2023/12/why-scientists-are-making-transparent-wood/ (accessed Jan. 24, 2024).

[2] S. Fink, “Transparent wood – a new approach in the functional study of wood structure,” Holzforschung, vol. 46, no. 5, pp. 403–408, Jan. 1992. doi:10.1515/hfsg.1992.46.5.403

[3] M. Tavel, “What determines whether a substance is transparent? For instance, why is silicon transparent when it is glass but not when it is sand or a computer chip?,” Scientific American, https://www.scientificamerican.com/article/what-determines-whether-a/ (accessed Feb. 24, 2024).

[4] Eero Sjöström, Wood Chemistry: Fundamentals and Applications. San Diego: Academic Press, 1993.

[5] S. Wills, “Your next windowpane: Transparent wood?,” Optics and Photonics News, https://www.optica-opn.org/home/newsroom/2016/august/your_next_windowpane_transparent_wood/ (accessed Jan. 24, 2024).

[6] C. Montanari, Y. Ogawa, P. Olsén, and L. A. Berglund, “High performance, fully bio‐based, and Optically Transparent Wood Biocomposites,” Advanced Science, vol. 8, no. 12, May 2021. doi:10.1002/advs.202100559

[7] N. St, “Wood that could be mistaken for Glass,” The New York Times, https://www.nytimes.com/2016/05/12/science/see-through-wood.html (accessed Feb. 24, 2024).

[8] Q. Xia et al., “Solar-assisted fabrication of large-scale, patternable transparent wood,” ScienceAdvances, Jan. 27, 2021

[9] S. Liverani, “Transparent wood windows could be key to better energy efficiency,” The American Ceramic Society, https://ceramics.org/ceramic-tech-today/transparent-wood-windows-could-be-key-to-better-energy-efficiency/ (accessed Jan. 24, 2024).

[10] P. by A. Androff, “Transparent wood could be the window of the future,” USDA, https://www.usda.gov/media/blog/2020/10/01/transparent-wood-could-be-window-future (accessed Jan. 24, 2024).

[11] I. Wachter, T. Štefko, and P. Rantuch, Transparent Wood Materials Properties, Applications, and Fire Behaviour, 1st ed. 2023. Cham: Springer Nature Switzerland, 2023. doi: 10.1007/978-3-031-23405-7.

[12] “Orange Peel makes transparent wood more sustainable,” Materials Today, https://www.materialstoday.com/biomaterials/news/orange-peel-transparent-wood-sustainable/ (accessed Jan. 24, 2024).