The history of the harp goes back thousands of years. The harp is regarded as the world’s oldest string instrument. It influenced the evolution of the piano, guitar, and violin. Engineering is the application of science to the art of problem solving; the harp has encompassed the ideals of engineering. Through many centuries, harp makers have been committed to satisfying the evolving demands of musicians by devoting themselves to improving the instrument’s sound quality. Engineering developments in the harp’s structural, mechanical, and ergonomic aspects have improved its sound and led to the creation of the single action harp, double action harp and electronic harps. Good engineering has helped create beautiful, soothing music that brings peace and tranquility to the people worn out by the demands of daily life.

Introduction

Many do not consider the harp as an example of engineering advancement because it is not a typical technological development. Engineering is defined as the application of science to problem solving in practical scenarios. It is fascinating to note that the development of the harp has encompassed the ideals of good engineering. For many centuries, harp makers have been committed to satisfying the evolving demands of musicians through improvement in the instrument’s sound quality.

Engineering developments in the harp’s structure, mechanics, and ergonomics have improved the sound of the world’s oldest string instrument (see Fig. 1); these changes were reflected in three major modifications of the harp since its inception. The first change occurred in the 1700s when pedals were added to the harp. This addition introduced the single action harp, which allowed the pitch of the instrument to be raised half a step. In the late 1700s, the harp was modified further and it was then possible not only to raise the pitch but also to lower it by half a step. The double action harp was invented in 1801 as a result of the need for a broader range of pitch. With the dawn of the computer age, the instrument was computerized in the 1980s leading to the creation of the pneumatic computerized harp. Figures 2 and 4 are examples of songs played on a harp (see Fig. 2 and Fig. 4).

Anatomy of the Harp

The harp consists of three basic structural components: the strings, the resonator (also known as the soundboard) and the neck [1]. Principles behind the musical string are simply an “ageless phenomenon of physics” [2]. When a string is plucked, it will continue to vibrate until its energy is depleted. As the string vibrates, it causes the air around it to move. The soundboard acts as a wall and causes a mass of air to move and translate the massive waves of sound pressure into the beautiful sounds of the instrument.

While all the strings have the same function, different types of strings produce varying frequencies just as the different types of reed in woodwind instruments produce different sounds. Thinner and lighter strings, which vibrate more rapidly and produce higher tones, are located near the shoulder of the harp while the thicker and heavier strings, which vibrate slower and produce lower tones, are located near the forepillar of the harp [2]. The strings are made out of gut, except for the heaviest of the bass strings, which contain copper wound over a silk core. The strings must be tensioned in order to produce music and the soundboard and neck are the mechanisms that achieve this. One end of the string is attached to the soundboard and the other end is attached to the neck directly with special knots or indirectly to fixed plugs, movable tuning-pegs, or tuning rings.

Stepping It Up

Those who are familiar with the harp may be surprised to discover that the pedals are not considered a fundamental component of the harp. The reason for this is that pedals were not added to the harp until the 1700s. The addition of the seven pedals was a result of growing demands from harpists for an instrument that was capable of a broader range of pitch. These seven pedals introduced the single action harp to the music world. This move towards the single action harp, something comparable in its effect to the invention of the MP3 player in our times, was considered a great progression towards improving the sound of the harp. The seven pedals built into the base of the harp could raise the pitch by half a step. For instance, if the harp were tuned to C-flat, then depressing the pedal would raise the C strings to C-natural.

The pedals were connected to metal rods, which passed through the forepillar to the top where the chromatic action was housed inside the curved neck. The action of the pedal moved a long semi-flexible steel strip laterally along the length of the action. Attached to the strip, at each octave, was a crank that pulled the string onto a fret by means of an adjustable crochet, a hook mechanism. The crochet regulated the raising of the pitches by moving horizontally inwards towards the neck where it shortened and tightened the string when the pedal was depressed. A higher pitch was produced as a result of the increased string tension (see flash demo). With the range of pitches the single action harp was now able to achieve, one would think that harpists and music listeners would be satisfied. This, however, was not true.

The introduction of the seven pedals did not solve all the problems and concerns that the harpists had with the instrument. In fact, it caused new problems: The hollow forepillar and neck, now hollowed and straightened to house the metal rods, made the harp extremely weak. The weak neck and the staved body meant that string tension had to be lower, which affected the maximum sound potential. The sonority of the strings became dull and buzzing began to occur due to the lower string tension. Furthermore, harpists were looking for the ability to not only raise the pitch but also lower the pitch half a step. Once again, instrument makers were relied upon to come up with practical solutions to address these concerns.

Achieving Perfection: the Double Action Harp

Sebastian Erard, an ingenious instrument maker and businessman, presented practical solutions that “represented a radical change in the construction of the single action harp” [1]. A new body design was introduced. The soundboard was made stronger by building it in two parts: a rounded back reinforced by internal ribs [1].

Secondly, a new neck design also improved strength and stability. The action that was originally in the neck was now housed in a pair of brass plates and mounted to the neck. Moreover, the use of laminated wood added strength to allow for a longer string life and an improvement in the evenness of string tension. The really revolutionary feature of Erard’s modifications was his design of the “fork” system. He replaced the crochet with two brass prongs mounted on rotary discs, which produced a smaller displacement and reduced string breakage. Under this mechanism, when the pedal is depressed, the axis rotates to bring the prongs into firm contact with the string, thus tightening it. This modification also solved the problem of buzzing strings.

Even with the great modifications of the harp, musicians were not happy with it. “In spite of mechanical and constructional improvements, musicians and harp makers alike were dissatisfied with the tonal and modulatory limitations’ of the single action harp” [1]. A complicated design of fourteen pedals that could play in all keys was briefly examined to solve the tonal limitations. The design, however, was too complicated and inefficient to satisfy harp makers and harpists. It involved placing another set of seven pedals below the existing set, something very inconvenient for a harpist trying to operate fourteen pedals with two feet.

The Double Action Harp

The changes Erard implemented on the single action harp paved the way for his invention of the double action harp in 1801. Erard’s double action harp was an example of using very simple mechanics to produce a complicated motion. The result was simple, elegant and mechanically logical. Based on his “fork” system, Erard’s double action harp consisted of seven pedals where each could be depressed twice. Each string passed between two fork-bearing discs that were placed one above the other.

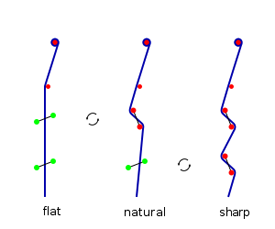

When the pedal is depressed into its first notch, the upper disc turns so that the prongs grip the string and raise the pitch by half a step, while the lower disc turns about 45 degrees but does not touch the string. When the pedal is depressed into the second notch, the lower prongs turn an additional 35 degrees, grip the string and raise the pitch by another half step. The addition of the second set of rotary discs, allowed the harp to be sharpened to two semitones, from flat to natural to sharp, making the harp capable of producing any key (see Fig. 3).

The double action harp became the standard for harp players and orchestras. Harp makers implemented ergonomic modernizations to the double action harp that made it even easier for harpists to play. While the traditional length of the strings and overall height of the forepillar were retained, the height of the harp at the neck near the highest strings was lowered.

This permitted the harpist’s arms and hands to be held in a more comfortable lower position while playing the uppermost strings [1]. Harp makers also introduced a progressive gradation for the angle of the strings to one another in a manner that made the angle between the harpist’s fingers and the strings remain the same from the middle to the highest range of the harp [1].

The Computer Age

As computers started to dominate all aspects of life, musical instruments, including the harp, were not left untouched. A “memory” harp moved the oldest string instrument into the computer age in the 1980s. The “memory” harp was a pneumatic, computerized harp that had a laser-made, pinch-type mechanism. This mechanism allowed a small computer to organize the function of the pedals by allowing the harpist to record the pedal moves needed in order to perform a particular piece of music and program this information onto a card about the size of a credit card. Later on, the touching of only one pedal would cause one or several pedals, as they were needed, to be moved.

In addition, the electronic MIDI (Musical Instrument Digital Interface) Harp was developed in the late 1980s and early 1990s. Like a keyboard, the MIDI harp could be programmed to sound like any instrument; a musician could pluck a string and make it sound like a flute or even like the harp. The MIDI harp however had a disadvantage; the sound was too “electronic”. It did not have the acoustics of a real harp. As a result of the poor sound, the GigaHarp was developed in 1999. The GigaHarp allowed the electronic harp to replicate high quality harp sounds through any MIDI keyboard. These technological developments transform the harp, “one of the oldest of musical instruments, into one of the newest of the twenty-first century” [3].

Conclusion

The harp has gone through many modifications and advancements to perfect the sound quality and to satisfy harpists. These improvements are examples of applying the principles of engineering to solve problems related to sound quality, structural stability, mechanical efficiency, and ergonomics. In thinking of the scope of engineering being limited to just inventing sophisticated gadgets to perform astonishing feats, we may often overlook the fact that good engineering appears in even the most artistic endeavors such as music. The harp is a prime example of scientific applications used to improve and produce the beautiful and soothing music of a musical instrument that for 5000 years has been able to bring serenity to those who are frazzled by the demands of daily life.