The field of chemical engineering has existed since World War I, yet many may have trouble describing what a Chemical Engineer actually does. Chemical Engineering has allowed Americans to enjoy a higher quality of life through the benefits of the products these engineers produce. In fact, industrial processes used by Chemical Engineers are so widespread that we find them in our everyday activities. For example, the distillation process that is employed in the recovery of uranium is the same as that used in making coffee. Through the examination of a typical day in the kitchen, this paper will provide everyday examples of the less widely known industrial applications, including solid-liquid extraction, gas absorption, adsorption, and distillation.

Chemical Engineering is Vital to How We Live

Consider your food intake on a typical day. You may not realize that chemical engineering processes similar to those used in an oil refinery are behind many common food items. You may wake up and make yourself a cup of coffee to start off the day. Then to make sure that your stomach will not start groaning, you have a bowl of cereal – let’s face it, who has time to make anything more elaborate in the morning? Later, when you arrive at a friend’s house for a barbecue, you realize that he has not started the fire yet. To stop your complaining, he offers you a soda. Later on, you return home to get ready for your date, for whom you have promised to make a romantic dinner. In your best attempt, you prepare chicken Marsala, chicken filets sautéed in wine sauce, and serve it over bow-tie pasta. Surprisingly, every one of these meals relies on various chemical engineering processes.

What is Chemical Engineering?

To many, chemical engineering is a vague subject at best. Most Americans might only be able to describe chemical engineering as the science of making chemicals. But what is a chemical? Surely, petroleum and pharmaceutical compounds are chemicals, but can this category be expanded to include cooking? Webster’s Dictionary defines a chemical as “a substance obtained by a chemical process.” A process in this sense is any chemical mechanism that is implemented to transform raw materials into desired products [1]. The two principal chemical mechanisms include, converting the individual molecules contained in the sample or changing the concentration of these compounds in the sample. Food is a chemical in this sense, since one makes the final product by combining and changing various raw materials. Cooking is a form of engineering because it involves the use of materials for the benefit of mankind [2].

Breakfast of Champions: A Cup of Joe

When you roll out of bed and start the coffee maker, you might be too busy trying to keep yourself awake to worry about the science that is about to transpire. Nevertheless, coffee making is a prime example of one fundamental chemical separation process: solid-liquid extraction, which is also known as “leaching” or “washing.” Water is the liquid used to extract coffee particles from the mixture of solids contained in the coffee grounds. When you roll out of bed and start the coffee maker, you might be too busy trying to keep yourself awake to worry about the science that is about to transpire. Consider what happens when you reuse coffee grounds several times: with each brewing, your coffee becomes more dilute due to the decreasing concentration of coffee particles left in the solid mixture.

The filter is a convenient means of separation; it allows solids dissolved in a liquid to pass through, while keeping the undissolved solid behind. For a solid to dissolve in a liquid the two must have similar polarity (polarity is the measure of how unevenly electrons are distributed around a molecule). Fortunately for coffee drinkers, coffee particles will dissolve in water because both the solvent (water) and the solute (coffee) are polar; that is, both have an asymmetrical arrangement of electrons. If coffee were nonpolar, it would require a nonpolar solvent [3], such as vegetable oil–an unpleasant prospect for your morning caffeine rush.

Chemical engineers use solid-liquid extraction for other purposes as well. For example, uranium is separated from low-grade ores in the same manner that coffee particles are separated from coffee grounds. In this application, the water must be acidified with sulfuric acid or sodium carbonate in order to extract the uranium. In order to be soluble in water, a polar substance, the uranium must first be ionized. The most cost-effective means of accomplishing this is the use of an acid, which eagerly accepts electrons from the neutral uranium, polarizing it. Now the positively charged uranium will dissolve in water because ions are simply an extreme form of polar molecules. After the uranium is separated from the ore by the means of a filter, it can be further refined so that it is capable of releasing energy through nuclear fission.

Breakfast of Champions: Cocoa Puffs

Let us return to our morning routine. While your coffee is brewing, you start to make yourself a bowl of cereal. When adding milk to your Cocoa Puffs, you generally do not have to worry about whether the cereal has gone bad. Milk, on the other hand, which is prone to spoiling, is made up primarily of water with lactose sugar and fat globules suspended in it. The lactose will remain dissolved indefinitely, but the fat globules will separate from the mixture over time. This process is commonly known as curdling. The two parts, or phases, separate in this way because molecules tend to attract other molecules of the same polarity. Oil and fat globules are nonpolar, whereas water, vinegar, and lactose are polar. This explains why in both examples the lighter nonpolar molecules will separate and float on the polar water solution.

To increase the useful lifetime of milk, chemical engineers devised a way efficiently to remove most of the fat globules from the milk before it is distributed. Rather than wait for the two phases to separate on their own, dairy farmers use centrifuges to speed up the process. Centrifuges are machines that spin a sample in circles, taking advantage of centripetal acceleration to separate the phases by their density. When the centrifuge comes to a stop, the milk is almost entirely separated into the two phases. Then the heavier water phase can be simply drained off the bottom of the container. This non-fat milk can be mixed with the desired amount of fat to produce everything from double cream (48 percent) to one percent milk. This separation process increases the useful lifetime of milk and saves you from curdled Cocoa Puffs [4].

The Barbecue: There is Nothing Worse Than Flat Soda

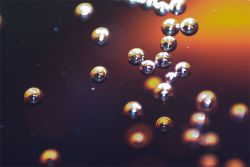

As far as carbonated beverages are concerned, there is nothing worse than a flat soda. Carbonation is an example of gas absorption, where a gas, in this case carbon dioxide, is transferred to a liquid (Fig. 1). This vapor-liquid equilibrium occurs spontaneously when the gas and liquid have the same polarity. However, carbon dioxide is nonpolar and, as mentioned earlier, water is polar. This instability is what causes the bubbles to come out of solution rapidly once the can is opened.

As far as carbonated beverages are concerned, there is nothing worse than a flat soda. Carbonation is an example of gas absorption, where a gas, in this case carbon dioxide, is transferred to a liquid (Fig. 1). This vapor-liquid equilibrium occurs spontaneously when the gas and liquid have the same polarity. However, carbon dioxide is nonpolar and, as mentioned earlier, water is polar. This instability is what causes the bubbles to come out of solution rapidly once the can is opened.To overcome this instability during packaging, chemical engineers determined that the application of higher pressure would force the carbon dioxide into the soda. At higher pressures, carbon dioxide dissolves because liquids occupy much less volume than gases. To lessen the strain of the pressure, the carbon dioxide gas dissolves and becomes part of the liquid. The carbon dioxide remains in the soda until the pressure is released, which occurs when the can is opened. Once you open the can, much of the carbon dioxide escapes immediately, leaving the rest to come out of solution at a decreasing rate until the soda is flat [5].

The Barbecue: What Goes Into the Coals

While you are drinking your soda, your friend drops a match into the self-lighting charcoal to ignite it. This charcoal has had combustible organic vapors similar to those found in lighter fluid adsorbed onto it. These nonpolar vapors dissolve spontaneously into the nonpolar charcoal due to their similar polarity. This ability to adsorb is enhanced by the fact that charcoal has an enormous surface area to volume ratio. An important characteristic of any adsorbent, the large area creates more locations for the other substance to attach [4]. As a result, self-lighting charcoal is relatively easy to produce, which keeps this luxury item within your budget and aids you in making the perfect hamburger.

Adsorbent polar vapors dissolve spontaneously into the nonpolar charcoal due to their similar polarity. This ability to adsorb is enhanced by the fact that charcoal has an enormous surface area to volume ratio. An important characteristic of any adsorbent, the large area creates more locations for the other substance to attach [4]. As a result, self-lighting charcoal is relatively easy to produce, which keeps this luxury item within your budget and aids you in making the perfect hamburger.

Adsorption is also implemented in a machine called a chromatographer, which separates the different components contained in a liquid or gas sample. As the fluid passes over the adsorbent, the components are retained for different amounts of time depending on their affinity towards that adsorbent. This affinity is related to many factors including polarity, size, and specific groups of atoms contained in the molecules. Then as the fluid exits the machine, the compounds with the least affinity to the adsorbent exit first while the compounds that are most similar to the adsorbent exit last.

Dinner for Two

After your long day of cooking with chemical engineering processes, you should be able to prepare the pasta and chicken Marsala simultaneously. In fact, you have to because you ran late getting ready for your date, when you stopped to compare your lunch to the work of a chromatographer. You set the water for the pasta to boil and start to prepare the chicken. Then after cooking the pasta to the desired firmness, it can be physically separated from the water by use of another filter, the strainer. This device is similar to the coffee filter used at breakfast; it is a physical barrier used to separate the solid and liquid phases. Also notice that the waton is also implemented in a machine called a chromatographer, which separates the different components contained in a liquid or gas sample. As the fluid passes over the adsorbent, the components are retained for different amounts of time depending on their affinity towards that adsorbent. This affinity is related to many factors including polarity, size, and specific groups of atoms contained in the molecules. Then as the fluid exits the machine, the compounds with the least affinity to the adsorbent exit first while the compounds that are most similar to the adsorbent exit last.

Now to sautée, you warm a mixture of white wine, flour, various seasonings, and the chicken until the sauce is relatively thick. This setup is a crude distillation device, which concentrates the higher boiling compounds by first boiling off a disproportionately large amount of the lower boiling compounds [5]. Everything except the wine has a very high boiling point that is simply unattainable on your stove; if this were not the case, you would have gaseous chicken. The wine, however, contains alcohol and water, both of which will boil at a more reasonable temperature. Consequently, the sauce will thicken as the wine is distilled out of the mixture, which still contains all of the flour, seasonings, and chicken. The amount of alcohol and water remaining depends on how long the mixture is heated.

This distillation process is in essence the same as that used in the oil industry. In a given oil refinery, countless distillation towers are used to separate lighter hydrocarbons from heaver hydrocarbons and impurities. This ability is vital to increasing the efficiency of all petroleum fuels, in the same way that it is useful for giving the sauce the perfect thickness. In each tower, the lighter components vaporized and separated off the top, while the higher boiling components are drained off the bottom. These towers allow crude oil, a thick tar-like substance, to be separated and further subdivided into natural gas, butane, propane, jet fuel, gasoline, diesel, naphtha, and asphalt. Without this process, we would have no fuel for the internal combustion engines that make possible the global environment that we live in today. In the same way that cars cannot function without distilled crude oil, people too would be scarce on fuel for their biological combustion engines if palatable food could not be concocted by the chemical processes thined off the bottom. These towers allow crude oil, a thick tar-like substance, to be separated and further subdivided into natural gas, butane, propane, jet fuel, gasoline, diesel, naphtha, and asphalt. Without this process, we would have no fuel for the internal combustion engines that make possible the global environment that we live in today. In the same way that cars cannot function without distilled crude oil, people too would be scarce on fuel for their biological combustion engines if palatable food could not be concocted by the chemical processes that are performed on the stove.

Conclusion

Without chemical engineers, the quality of our lives would surely suffer. The food industry is just one example where chemical engineering processes have made it possible for us to enjoy the luxury that we have become so accustomed to. As we have seen, chemical engineering is involved in everything from obtaining weapons-grade uranium to producing the gasoline that powers your car. By using the familiar processes of cooking to examine chemical engineering principles, we can more easily understand their industrial applications. So the next time you are making a cup of Joe, take pride in the fact that you now know the chemical engineering that makes it work.

References

-

- [1] R. M. Felder and R. W. Rousseau. (2000). Elementary Principles of Chemical Processes. New York: John Wiley & Sons, Inc.

- [2] C. J. Gunn, L. L. Leone, and W. C. Oakes. (2000). Engineering Your Future. St. Louis: Great Lakes Press, Inc.

- [3] C. B. Fryhle and T. W. Graham Solomons. (2000). Organic Chemistry. New York: John Wiley & Sons, Inc.

- [4] M. M. Abbott, J. M. Smith and H. C. Van Ness. (2001). Introduction to Chemical Engineering Thermodynamics. New York: McGraw-Hill.

- [5] L. B. Anderson, C. W. Clump, A. S. Foust, Louis Maus and L. A. Wenzel. (1990). Principles of Unit Operations. Malabar, Florida: Robert E. Krieger Publishing Company.

- [6] D. C. Harris. (1999). Quantitative Chemical Analysis. New York: W. H. Freeman and Company.

- [7] A. M. Webster. (1961). Webster’s New Collegiate Dictionary. Springfield, Massachusetts: G. & C. Merriam Company.