Introduction

Most people are familiar with tofu and the fact that it is a soy-based product; however, very few actually know what goes into the process of turning soybeans into the white blocks of tofu that are available at the grocery store. While people have been making tofu for hundreds of years, the once traditional methods that utilized wooden presses and nigari, a coagulant derived from deep sea water that is primarily magnesium chloride [3], are becoming increasingly mechanized assembly lines, engineered to produce tons of tofu everyday.

The Beginnings of Tofu

Following World War II, there was a brief surge of American interest in tofu due our increased interactions with East Asia; however, this quickly diminished and it was not until 1975 and the publication of The Book of Tofu [3], that the popularity of tofu was here to stay in the United States. The Book of Tofu provided descriptions of various tofu types, nutritional information, and other facts about tofu that the American public simply did not know at the time.

In all tofu processes, the first step is making the soymilk; in which the key to success is selecting soybeans of optimal ripeness. While most people are familiar with the edamame stage of the soybean that holds a bright green color, this is still an early stage in soybean development. The soybean reaches full ripeness weeks later when it has developed an off-white color, as shown in Fig. 1. Once beans of proper ripeness are allocated, it is best to husk the beans before placing them in cold water, where they soak for 10 to 13 hours [7]. The soaked beans are then ground and heated to make the extraction of protein easier. The finer the grind, the better the yields. Once ground, the slurry is filtered to dispose of the pulp and course material from the grinding stage, resulting in soymilk [7].

Once soymilk is obtained, a coagulant is added to the batch, either traditional nigari or calcium sulfate, which is primarily used in modern tofu processing. Calcium sulfate results in a faster process and higher yields, although some prefer the taste created by the use of nigari [5]. The coagulant allows soybean curds to form in the soymilk batch. These curds are then collected and placed into forming boxes that press out excess water and give tofu its cubic shape. Since World War II, a pasteurization step concludes the process after packaging, in which the packaged tofu is set in water, boiled to kill bacteria, and then cooled right after [5]. This step has allowed the shelf life of tofu to increase by weeks and has made it conventional to distribute the tofu over long distances that in the past took too long and resulted in decreased freshness.

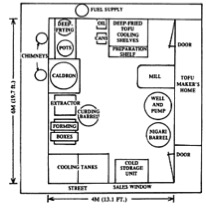

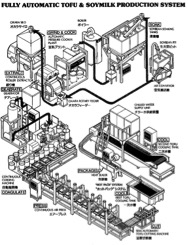

Tofu comes in many forms that include firm, silken, and fried, and with these many types come many different methods of preparation. The main styles of tofu making facilities include: the traditional cauldron shop, the steam cooker plant, the pressure cooker plant, and the automatic steam cooker plant which is the precursor for the modern factory [5]. While the general methods of preparation have remained the same, recent innovations in sanitation and pasteurization, as well as the overall mechanization of the food-processing industry, have led to increased production and distribution of tofu across the world [5]. While traditional cauldron shops have the capacity to process about 55 pounds of dry soybeans a day, modern factories have the ability to process 390 pounds of dry soybeans every hour [5].

The Traditional Cauldron Shop

First, stone mills are used to grind the soybeans after they have gone through the soaking process. These stone mills utilize a vertical axis that is rotated by hand [5]. Cauldrons are mostly made of iron or steel and are used to cook the soy slurry created by the stone mill. Lastly, the press is used to separate the liquid from the soy slurry after heating in the cauldron. The most simple and utilized style of lever is called the simple lever press, where a plank of wood is inserted into a hole in a wall

and rested atop a pressing sack placed on a curding barrel [5], as shown in Fig. 3. The pressing sack resembles a bag made of cheesecloth and contains the heated soy slurry. Upon pressing the lever on the sack, the liquid contents drip into the curding barrel where the tofu curds are collected and then pressed into tofu blocks [5].

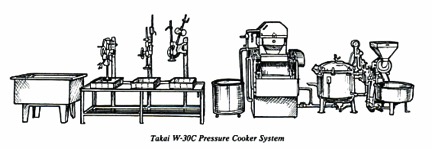

The Pressure Cooker Plant

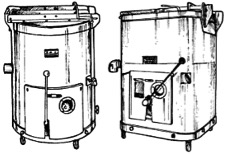

While the techniques of the pressure cooker plant are rather similar to traditional cauldron shop styles, differences in equipment include the boiler, the pressure cooker, the extractor, and the packaging system [5], all of which can be seen in Fig. 4. Another difference is that unlike the wooden equipment used in cauldron shops, most modern facilities use stainless steel equipment that increases the hygiene of the process, as bacteria can accumulate in the grains of wood quite easily [5]. While boilers vary in size, capacity, and material, most are steel or cast iron. Boilers work by creating reservoirs of pressurized steam that are used for quick and efficient cooking of the soybean slurry that results from the mashing of soaked soybeans [5]. Likewise, the heat generated by the boiler can be used in other processes and cleaning that in the past have taken longer due to the need to create heat using a flame.

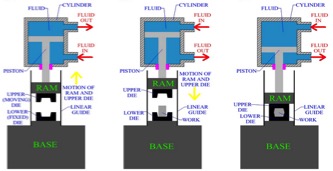

The third piece of machinery used is an extractor, which is primarily a hydraulic press. The cooked soybean slurry is placed into a pressing sack rested upon a perforated platform in the press [5]. The hydraulic press utilizes the differences in two fluids’ pressures to move a piston up or down [9], as shown in Fig. 6. When a lever is pulled, either the fluid chamber above the piston is filled with more fluid, typically an oil, to move the piston down, or the bottom chamber is filled to move the piston up. This utilization of fluid pressures makes this process much less strenuous than traditional press levers that relied primarily on the exertion of human strength. While there are other types of extractors such as screw and jack extractors, the hydraulic press is by far the most utilized extractor today due to its efficiency and ease [5].

The final step of production is packaging the resulting tofu product. In the past, a lack of packaging technology led to an inability to produce and distribute tofu on a large-scale. The two primary methods of packaging used are vacuum sealing, which leaves the product free of water and air, and a method where heat is utilized to seal a container of tofu submerged in water with a plastic film.

Conclusion

References

-

- [1] (2012, April). Sustainable Soy [Online]. Available: https://www.house-foods.com/uploads/sanasustainabilitydeck.pdf

- [2] (2013, September 26). Major Cuts of Greenhouse Gas Emissions from Livestock Within Reach [Online]. Available: http://www.fao.org/news/story/en/item/197608/icode/

- [3] W. Shurtleff. (2007). History of Tofu [Online]. Available: http://www.soyinfocenter.com/HSS/tofu3.php

- [4] T. Watanabe. Science of Tofu. Kyoto, Japan: Food Journal Co. 1997. Available: https://dlmarket-jp.s3.amazonaws.com/download/44/4436/Science_of_tofu_sample.pdf

- [5] W. Shurtleff and A. Aoygi. The Book of Tofu Volume II. Lafayette, CA: Soyfoods Center, 1979. Available: http://books.google.com/books?id=sYUq27wYcKMC&pg=PA35&lpg=PA35&dq=traditional+tofu+methods+vs+present+methods&source=bl&ots=P_tdVo7fdB&sig=3YF6BIVHMwOGvJN5vVGDzOhBiTc&hl=en&sa=X&ei=ayX7UtqSI6TL2QX_-oCwBw&ved=0CFYQ6AEwBg#v=onepage&q=traditional%20tofu%20methods%20vs%20present%20methods&f=false

- [6] Marybeth. (2013, October 9). What Do Soybeans Look Like [Online]. Available:

- https://www.google.com/search?q=historical+tofu&source=lnms&tbm=isch&sa=X&ei=tOL7UurPMeTr2QX-jYHYAw&ved=0CAcQ_AUoAQ&biw=1163&bih=530#q=soybean+ripe+stages&tbm=isch&facrc=_&imgdii=_&imgrc=WCx4X7GSQ8zTLM%253A%3Brf4C9__0pCz10M%3Bhttp%253A%252F%252Fwww.agricultured.org%252Fwp-content%252Fuploads%252F2013%252F10%252Fsoybean-pods_thumb.jpg%3Bhttp%253A%252F%252Fwww.agricultured.org%252F2013%252F10%252F09%252Fwhat-do-soybeans-look-like%252F%3B602%3B482

- [7] Tofupedia. Available: http://www.house-foods.com/tofupedia/

- [8] Nathan. (2013, February 5). How Pressure Cookers Work [Online]. Available: http://modernistcuisine.com/2013/02/how-pressure-cookers-work/

- [9] Hydraulic and Mechanical Presses [Online]. Available: http://thelibraryofmanufacturing.com/presses.html

- [10] How Chamber-Style Vacuum Sealers Work [Online]. Available: http://www.chefsteps.com/activities/how-chamber-style-vacuum-sealers-work

- [11] System Flow [Online]. Available: http://www.takaitofu.com/english/home/hm05.html