Long before the age of computers, light bulbs, automobiles, or locomotives, a revolutionary feat in engineering transformed society. This technology almost singly separates developed countries from their developing counterparts, and many Americans take it for granted. Rarely do we ever think about it when we use it, and when we do, it’s generally because it has broken down. Most of us probably care not to think about it too much. To garner a greater appreciation for this technology, imagine not having access to a toilet, a drain, or portable water. Such reflections highlight the importance of sewage systems and treatment facilities in our lives. They may be the most important engineering development in modern society.

History

Technology for piping away human waste has its origins as far back as 4000 BCE. Archeological evidence suggests that pipes to carry waste existed in the Babylonian empire, as well as in the primitive sewage systems of Scotland. The crowning achievement of water management in ancient times was the Roman sewer system, which employed artificially constructed drains to carry sewage away from major cities [1]. Later, during the dark ages, governments reverted to disposal methods that didn’t control or treat the flow of wastes in any significant way [1]. Widespread mismanagement of waste continued into the middle ages and led to massive plague outbreaks, contaminated water supplies, and numerous deaths [1].

As cities grew progressively larger, conditions became so poor that European royalty set forth decrees requiring people to meet minimum sanitary standards. However, such decrees were largely ineffective in stemming the flow of raw sewage in the streets. It eventually became obvious that cities needed to rid their wastes in a more sanitary manner. Hence, the construction of first modern sewer system in the world began in Hamburg, Germany in 1840 [1. After a fire destroyed much of the town, the residents redesigned the city to their liking. Because of their distaste for waste, they included sanitation in their plans.

After Hamburg’s success with waste management, people began to understand how important sewage systems were to public health. Paris, London, and Berlin created their own sewage systems. However, treatment of sewage was still minimal, as were methods for transporting waste. Thomas Crapper’s invention of the toilet, along with other innovations, necessitated the creation of more advanced waste treatment and conveyance systems. In the early twentieth century, cities began to treat their waste, but more rural areas still had little or no sanitation. The only major treatment program in effect was the conversion of waste into fertilizer for agriculture. The rest of the untreated sewage was flushed in riverbeds and streams, contaminating the water supply.

Since then, many sanitation technologies have been developed to deal with sewage thanks to advances in environmental engineering. Two principal methods are urban sewer systems and septic tanks. Simply put, these solutions provide a centralized (sewer) and decentralized (septic) solution to human sanitation woes.

An introduction to sewer systems

If you live in a community that uses a sewer system, wastewater travels from your house to a main sewer line in the middle of the street. The diameter of the pipe exiting your house is only about three inches, but pipes progressively dilate to channels three feet wide [2]. Due to the force of gravity, sewage flows towards plants that process the waste. The process seems straightforward, but there are many factors an engineer must take into consideration to make a sewer system function properly.

To ensure gravity does its job, all sewer pipes must decrease in elevation with distance from the waste generator. If the pipes do not slope downward enough, the sewage will not flow fast enough and the pipes will clog. If pipes are graded too steeply, solid waste will separate from liquid and remain in the pipe, thus clogging it. Engineers developed special instruments, like the laser stabilizer, to determine the grade of sewer pipes.

Besides grading, maintenance and venting of pipes are critical and necessitate the placement of manholes in the street [2]. If not properly ventilated, gas buildup can restrict water flow through pipes. Moreover, without vents, clogged sewers could not be cleaned [2. To understand why vents are needed, try this simple experiment. First, try blowing through a whole straw. Next, cut several small holes in the straw and blow again. You should find the latter easier to blow through. Similarly, vents help to sustain flow through sewers. The placement of sewer manholes is critical because of the expense incurred with each installation. For this reason, manholes are placed at a set distance away from each other (approx. 100m, but the distance may differ based on pipe diameter) [2], with additional manholes installed at possible clogging points like intersections and curves in the pipe. Sophisticated camera systems, automated overflow devices, and chemical management stations are located throughout sewer mains to ensure proper sewage flow [3].

Treatment systems for sewers

As sewage passes through pipes, it eventually reaches the sewage treatment facility. Treatment of waste requires an incredible amount of engineering. The systems cities use to treat waste must be very reliable to make sure communities and the environment are not adversely affected by the wastewaters in sewers. Every day, Los Angeles alone produces three hundred and fifty million gallons of wastewater [4].

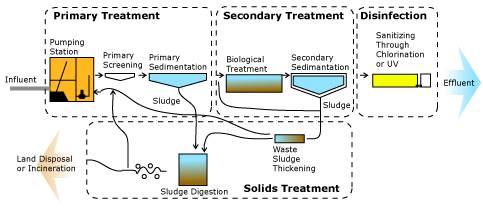

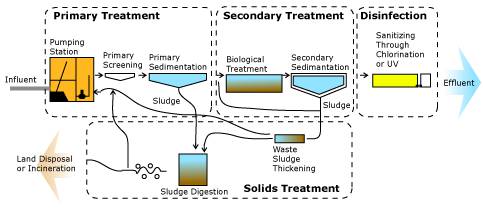

The basic treatment of water from sewers is divided up into three stages: primary treatment, secondary treatment and disinfection (Fig. 1).

Primary treatment

Primary treatment involves the screening and shredding of heavy materials in wastewater [5].

This allows solids to separate from the wastewater through sedimentation. After the solid material, or sludge, settles to the bottom, it is pumped away to be dewatered and either incinerated or disposed of in a landfill. The segregated wastewater is then pumped to the secondary treatment system.

Secondary treatment

The next stage in wastewater treatment, known as secondary treatment, exposes the wastewater to bacteria and other organisms that will consume and break apart organic material in the water and convert it to gases like methane and sulfur [2]. The process also reduces the amount of oxygen the effluent, or treated water, will need to finish biodegrading when it is transferred to a receiving body of water [5].

Two major techniques are used in biological treatment: the fixed film process and aeration. The fixed film process distributes wastewater over a large area where the waste percolates through a “film” of microbes that grow on the surface of the ground, breaking down any matter that floated through the sedimentation process [5]. The water percolates through the filter and eventually ends up in a drain at the base of the filter. It is then pumped to another sedimentation tank to allow any remaining sludge to separate from the water.

Aeration is significantly different from the fixed film process. Water is pumped through a tank foaming with bubbles generated by pumping air through perforated pipes beneath the tanks. This excess air promotes rapid bacterial growth on the organic material in the water to digest the material quickly [5]. The water is then pumped to another sedimentation tank, which allows any solid waste to fall out of the water and be pumped out as sludge.

Sterilization

After biological treatment is completed, the wastewater is filled with bacteria and microorganisms that could damage the environment and ecosystem in the vicinity of the water where the treated wastewater is dumped. Steps to sterilize or sanitize the water must be implemented to prevent these harmful organisms from leaving the treatment plant.

Two types of sterilization methods are commonly practiced at treatment plants. The conventional method is to chlorinate the water in large tanks called “contact basins.” However, chlorine has devastating effects when released in the surrounding environment. The other method is the rather new technology of ultraviolet sterilization [6]. This is much safer since no chemicals are released into the environment, but requires much more energy. After sterilization of the wastewater is completed, the effluent is released into a nearby waterway like a river or ocean, where it can safely reenter the natural water cycle.

Challenges facing centralized sewer systems, and engineering solutions

Despite its widespread use, generic sewer technology has difficulty conforming to every contour of the United States’ topography. Because sewers use gravity to pull the waste down the pipes, a sewer must be constructed in such a way as to ensure the flow of sewage towards a treatment facility. For this reason, sewer easements are generally located near rivers, creeks, or streams. However, many locations cannot rely upon gravity as the sole driver for the flow of the sewer system. Sometimes there are unavoidable changes in elevation that impede the flow of waste. Even flat elevations can make it difficult to construct a sewer that continuously decreases in elevation. To resolve this problem, engineers have created several different systems.

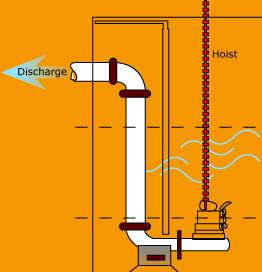

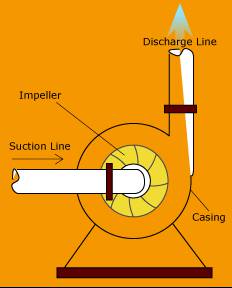

One such system is a grinder pump (Fig. 2). This pump grinds the material received from a dwelling and pumps the sewage up 150 feet or more through a pipe no more than a third of the diameter of the influent pipe [7]. Generally, these pumps are used in hilly areas away from large cities, making it possible for dense housing developments to be built on hills. Houses would have to be farther apart if septic tanks were used to treat waste. Another system used to move waste to a higher elevation is called a centrifugal lift station (Fig. 3). This system operates by pulling sewage to the center of a large fanlike apparatus. The spinning fan quickly separates the waste into compartments and accelerates it out the discharge line.

While increasing sewer versatility, pumps carry high maintenance and installation costs. In a good example of the expense of constructing lift stations for a major sewer system, the city of Boston spent $24 million for just one of eleven lift stations for its sewer mains [8]. This is a reminder of one of the most important factors affecting sewer systems: cost.

The majority of the costs involved in a centralized sewer system are associated with the maintenance of pipes and the energy used at wastewater treatment plants, although innovative engineering has allowed utilities to cut these costs. Many treatment plants attempt to recapture methane gas produced from the bacterial treatment of waste. This gas can be used to turn turbines that generate power for the treatment facility [9].

Although efforts have been made to survey pipes with closed circuit television cameras in manholes and stations that monitor the chemical properties of the sewage, the most effective advancement in managing sewers was the move to segregate domestic wastewaters from storm sewers. The construction of a separate set of sewers to handle storm runoff has proven expensive but has cut the cost on labor needed to replace and unclog pipes not designed to carry great amounts of large materials at once.

Other advances in sewer pipe technology exist besides relieving sewage pipes from the wear and tear of storm water. Materials engineers have developed new pipe materials to improve water transport efficiency and make pipes last longer. Today, construction of new sewers is carried out with poly-vinyl-chloride (PVC) material [2]. PVC is strong and non-reactive, allowing it to resist degradation from harsh minerals and chemicals. Unlike metal pipes, PVC does not oxidize, so the pipes’ interiors remain smooth and their integrity is maintained even after large amounts of water (an oxidizer) pass through it.

An introduction to septic systems

It is often impractical and costly to install sewer lines where there is either a great distance between residences or rugged terrain. In such cases, septic systems are a popular alternative to sewer systems. If you live far from an urban area, your house probably uses a septic tank. An astonishing twenty-five percent of United States residents use septic systems for their wastewater treatment.

A conventional septic system has three stages: wastewater collection, primary treatment (septic tank), and secondary treatment (soil treatment). After soil treatment, the water is considered free of potential materials (living and non-living) that could harm the environment.

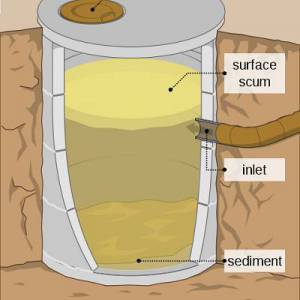

The septic tank

If you flush something down the toilet in your country home, it would travel through waste pipes just as if it were connected to a sewer. However, it will instead end up in a device known as a septic tank [10] where the waste will segregate. When entering a septic tank, the waste will pass through a baffle, a device that forces water and waste contents to be mixed in order to begin bacterial decomposition of the matter inside the tank. Inside the septic tank, the sewage will naturally separate into three layers [11]. The sludge will settle to the bottom, where it must be periodically pumped out. Water and liquids will remain in the middle, and a scum layer containing floating material such as oils and toilet paper will drift towards the top (Fig. 4).

After segregation in the septic tank, the segregated wastewaters exit through an outlet baffle near the top of the tank. The baffle prevents the scum layer from clogging the next stage of the septic system: filtration. This stage is commonly referred to as the “leach field” or “absorption field.” Two major conventional ways exist to filter wastewater: mounds and trenches [11].

A mound system works by elevating the wastewater with a lift station and then letting gravity pull the wastewater down through a series of perforated pipes branching out in a mound. To create a mound filter, a pit must be dug at least three feet into the ground and filled with an organic material that allows water to pass through easily, while ensuring adequate time for microbial digestion. A layer of sand is placed on top of the organic material which is then covered with a layer of rock containing the buried perforated pipes. Another layer of sand is then placed on top of the rock. Finally, the structure is covered with topsoil and sod grass. The water will percolate down from the pipe into the ground, where a natural “biomat” will form. The biomat is filled with organisms that consume harmful bacteria and anything else that did not decompose in the septic tank [11].

Trench systems are generally built in hilly terrain. They are laid out similarly to mound systems, but lack a mound. Initial construction of the trench system involves digging trenches up to several hundred feet long. Perforated pipes, surrounded by a layer of rock, are installed. A biomat forms around the layer of rock to dissolve the organic matter in the wastewater. Several terraces of pipes exist in this system. To maintain constant pressure on each of the pipe terraces, drop boxes are installed. These devices are filled through a pipe connected near the top of the box and drain to the perforated pipes located at the bottom of the box. As a drop box is filled, it spills into the next drop box. After filtration, the wastewater is considered treated and safe to enter groundwater reserves.

Engineering solutions to septic system challenges

While less costly than sewers, septic systems have their own set of problems. The United States Environmental Protection Agency reports that ill-managed and poorly engineered septic systems are the third largest source of groundwater contamination in the country [12]. Septic systems have also been linked to the destruction of coastal and lake ecosystems through shellfish contamination and overgrowth of algae in ponds. Poor filtration is mostly to blame for such problems. Successful filtering can only take place in optimal soil conditions, which are determined by several factors, principally soil permeability, saturation, temperature, and proximity to fresh water and bedrock [13].

Although septic systems can be managed by homeowners, a trained expert must evaluate whether the soil can support a filtration system. If the soil is already saturated, lacks adequate bacteria to kill harmful pathogens, is too cold to promote microbial growth, or is too close to groundwater (generally located above bedrock), then a conventional mound or trench system cannot be used.

For these reasons, environmental engineers have sought alternatives to the standard septic system that allow septic technology to work under these conditions. For instance, if the soil you wish to put your filtration system in is too poor or too cold to sustain adequate microbial growth for the breakdown of organic materials in the waste stream, then aerobic treatment units [13] may solve the problem. Septic tanks are generally sealed, so only anaerobic bacteria can survive in the wastewater. Aerobic treatment units pump air through bubbler jets into a special pretreatment tank that aerates and agitates the water, promoting rapid decomposition of any organic materials in the water just as the aeration process of centralized treatment plants does.

Peat pre-treatment filters [13] are another modification to the normal septic system that allow for the rapid digestion of material in the wastewater stream when adequate digestion through normal ground filters cannot be assured. Sphagnum peat is a material that “has an incredible water capacity, large surface area and chemical properties that make it very effective in treating wastewater [13].” A peat filter is constructed by digging large trenches and lining them with plastic material to prevent wastewater leakage into the surrounding area. After segregation in the septic tank, water is carried through a series of perforated pipes and permeates through a thick layer of peat, ending up at the bottom of a trough where the water collects into an underdrain pipe. It is then pumped into a normal mound or trench distribution filter. The peat creates an environment where microorganisms that aid in the decomposition of waste thrive. Adequate digestion in the peat filter may result in the final filter not having to produce many bacteria in order to filter the remaining wastewater.

Engineers have created numerous other methods for micro-wastewater filtration to compensate for poor conventional filtering. These include the creation of artificial wetlands, re-circulating media filters, and drip distribution systems. Also, environmental engineers have discovered that materials other than rock can be set around perforated filtering pipes; such materials can include things that would otherwise be thrown away, like used tires [14].

The bottom line on sanitation systems

It is unlikely that current owners of septic systems will continue to use them as decades pass. Despite the many improvements to septic systems, critics argue that due to the increasing densities of housing developments, septic systems will not be a viable alternative to sewers in new developments because there will not be enough land available to continue installing or using septic systems. Eventually, septic systems may likely be phased out in most areas [9] if engineers cannot make current septic technology compatible with denser populations.

Generally, sewer systems last much longer and are a safer, more manageable technology, despite their initial financial burden on the community. Owning a septic system demands proper maintenance from the owner, who must learn how and when to clean the septic tank and monitor the filtration system. The decentralized nature of septic systems leads to the problem of monitoring vast areas of soil to ensure proper filtration. Centralized treatment systems are easier to account for, and employ a staff of experienced professionals around the clock. However, high costs have created strong opposition to sewer installation in developing areas, which is unlikely to change anytime soon.

While the battle still rages on between septic system and sewer system supporters, engineers continue to formulate solutions to satisfy both sides, making centralized sewer systems more versatile and less expensive to build and maintain, while making septic systems more effective at treating waste.

Recently, engineers have even come up with a new hybrid mini sewer-septic system. This “cluster system” may be a solution for future developments [15]. Instead of having a septic tank for each home, several homes utilize one large tank and one large filtration system. This puts the responsibility for management of the system into the hands of professionals, yet cuts the cost of sanitation systems significantly. Currently, cities such as Mobile, Alabama have implemented the technology in a pilot program.

Engineers have played an integral role in maintaining our health and our environment by not only creating new technologies to treat wastewater from our homes, but also tackling ongoing problems that arise with the use of existing technologies.