Electronic ink mimics the appearance of ordinary ink on paper. It is currently used in cell phones, signs, and e-readers like the Amazon Kindle. There are many ways to imitate natural ink displays, but the most commonly used method is electrophoretic ink. This ink takes advantage of interactions between computer processors and charged black and white particles. The benefits of electronic ink displays over traditional LCD displays include improved readability, low power use, and flexibility. However, the devices are usually quite specialized, have little touch screen capability, and are less responsive than comparable LCD screen devices. These limitations are areas of current development for electronic ink manufacturers. Electronic ink devices have great potential for future applications, including conservation efforts. They could significantly reduce paper waste and tree consumption by replacing much of the current need for paper. As the field of electronic ink displays evolves, it is important to consider their current uses, the engineering behind the technology, their advantages and limitations, sustainability of the technology, and future development.

Introduction

““‘But in, you know, the Muggle world, people just stay put in photos.’

‘Do they. What, they don’t move at all?’ Ron sounded amazed. ‘Weird!’

Harry stared as Dumbledore sidled back into the picture on his card and gave him a small smile” [1]

Boarding the train to Hogwarts School of Witchcraft and Wizardry, Harry Potter discovers that photos in the wizarding world are not static like they are in the Muggle world. Images move, stirred by magic. Portraits smile and wave; landscapes shift and change over time. For us common Muggles, unfortunately, magic remains an elusive goal. The moving photos described above, however, may in fact be within reach with a relatively new technology called electronic ink. Thanks to this new development, we may soon be able to enjoy animated magazines, newspapers, and other printed material.

In fact, some publications using electronic ink have already hit the shelves. Esquire’s 75th anniversary edition featured the first-ever electronic ink cover in October 2008. Its headline blinked and flashed the words “The 21st century begins now” [2]. The issue is only the first of many that may possibly eliminate much of the current need for paper. Modern e-readers, such as the popular Amazon Kindle, already utilize electronic ink technology. This article dives into the technology that powers the Kindle: the engineering behind electronic ink, its benefits and limitations, its role in sustainability, and future applications.

Current Uses of Electronic Ink

Electronic ink is a technology that mimics the appearance and qualities of ordinary ink on paper, retaining images until electronically changed. It is manufactured by many companies in a variety of ways. The most notable are Xerox and E-Ink, which began developing electronic ink in the mid-1990s. By the early 2000s, products using electronic ink began to enter the market [3].

Electronic ink can now be found daily in various technologies. It has been used in the screens and keypads of mobile phones such as the Motorola F3 and Samsung Alias 2. It can be seen in various signs, billboards, and retail store pricing labels [4]. The most well-known current use of electronic ink, however, is in the screens of e-readers like the Amazon Kindle or Barnes & Noble Nook (Fig. 1). Amazon has sold an estimated 3 million Kindles, first released in 2007, demonstrating the commercial success of electronic ink [5].

How Does Electronic Ink Work?

There are many ways to make electronic paper displays that mimic the natural appearance of ink on paper, with each method varying by the manufacturing company. Currently, the most commonly used type of electronic ink works through electrophoretic technology. E-Ink, Gyricon, SiPix, and Bridgestone are among the companies that successfully use this method [4].

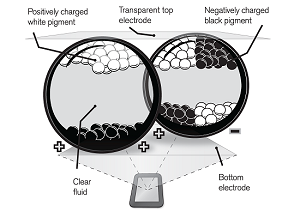

Electrophoretic ink takes advantage of different colored, oppositely charged particles moving into view to form patterns. Electrophoresis separates particles by their charge by applying voltage via electrodes; positively charged molecules are attracted to negative voltages, and negatively charged molecules are attracted to positive voltages.The ink itself consists of countless solid microcapsules that have three main components (Fig. 2) [6]:

• Negatively charged black particles

• Positively charged white particles

• Transparent liquid

Making the Ink

Electronic ink is engineered through a series of careful reactions. Production starts by coating black and white titanium dioxide particles with silicon dioxide. Appropriate polymers are added to the particles to give them their charge and to prevent them from sticking together. Next, the particles (less than 1 micron in size – that’s one 300th the diameter of a human hair!) are mixed with an oily liquid and chemicals that cause the particles to disperse evenly throughout the mixture. Finally, this mixture is emulsified into tiny droplets by adding water. Through chemical reactions, solid polymers materialize around the oil droplets, forming many 100 micron-long microcapsules [7]. The end result is displayed below (Fig. 3), which shows three examples of the microcapsules in different configurations.

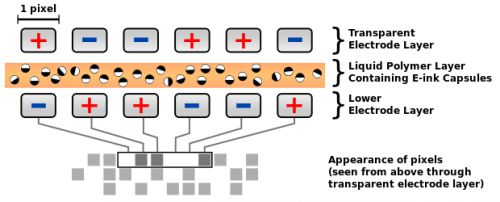

Printing the Ink and Making It Write

To make an electronic paper display, the electrophoretic ink can be printed on a variety of substances: glass, paper, plastic, and even fabric. In most current devices, the ink is bound to a sheet of plastic, forming an evenly distributed film of ink microcapsules. The plastic sheet is laminated to a layer of circuitry, which can apply different electric charges as directed by a processor [4]. Another transparent plastic layer is then applied on top, sandwiching the microcapsules between the two sheets of plastic (Fig. 3).

When the electrode below the layer of ink applies a positive voltage to the microcapsules, the negative black particles within the capsules are attracted to the positive charge, migrate to the bottom, and remain there until another charge is applied. Meanwhile, the positive white particles are repelled to the top. This is the ‘white’ state. When the electrode applies a negative charge, the opposite happens, leading to the ‘black’ state (in which we see the ink) (Fig. 3). The combined effect of the microcapsules’ visible colors forms text and images [4].

Adding Color to the Ink

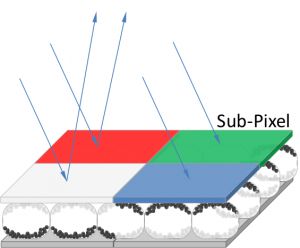

In late 2010, E-Ink announced that it had achieved color capability in its electronic paper displays through the addition of a color filter [8]. This filter, placed between the ink microcapsules and the transparent screen, has red, green, and blue components to create a full range of colors (Fig. 4). The desired colors are produced by arranging the microcapsules in appropriate patterns as directed by processors.

Use of Electronic Ink Displays Versus Traditional LCD Screens

One of the most cited benefits of electronic ink displays over traditional LCD screens is improved readability, since electronic ink is designed to mimic normal ink on paper. Some even claim that electronic ink displays reduce eye strain and are medically better for extended reading. This is untested and should not be the primary factor in deciding between ordinary LCD and electronic ink displays [9]. Electronic ink does, however, incorporate several features that make displays suited for comfortable reading. First, the surface of the electronic ink display is matte rather than glossy, eliminating glare. Furthermore, whereas LCD screens are backlit (emit light), electronic ink devices reflect ambient light. There is no backlighting, so electronic ink is easy to read in well-lit places. Due to the high contrast of the display, the ink can still be read in moderate to low lighting [10]. However, there may be a need for additional light in poorly lit areas.

An additional advantage of the lack of backlighting is improved battery life. Many e-readers can last for weeks on a single four-hour charge, which is also partially due to the fact that the devices draw power only when the text or image is changed [10]. Only when the image needs to be changed do the appropriate electrodes apply charge, drawing electricity. No energy input is needed to maintain an image on the screen because the particles in the microcapsules remain where they were last moved.

Electronic ink is capable of flexible and thin displays. Since the ink is generally printed on a thin sheet of plastic rather than on glass, the display can be much thinner and thus lighter. Plastic is also more durable and can withstand force without breaking like glass [11].

Sustainability of Electronic Ink

According to the Green Press Initiative, the U.S. uses more than 20 million trees to make paper for books and almost 95 million for newsprint each year. Approximately one-fourth of landfill content is paper products, which produce harmful methane gas as they decompose. The cost for the Harry Potter book series alone is estimated at 5.8 million trees, which could have been conserved through the widespread use of e-readers [12].

Electronic ink may help in sustainability efforts by replacing books and other paper products. Electronic ink price labels in retail stores can be reset at any time and reused, saving countless paper slips. One small e-reader can display many different books to a user, saving both landfill space and trees. A study performed by the University of Michigan estimated that the use of paper books led to four times more greenhouse gas emissions, three times more water usage, and thirty times more water consumption per person than the use of one e-book reader [13]. Another study at the University of California, Berkeley, showed that “reading a newspaper electronically released 32-140 times less CO2 and used 27 times less water” [14]. In addition to producing less waste and using fewer resources, electronic ink devices use little power, making them a viable replacement for paper products that produce waste and consume valuable trees.

Reading Into the Future of Electronic Ink

Several criticisms have been made about the current state of electronic ink displays and devices. They are less responsive to user input than LCD screens, and the refresh rate—the time it takes for an image to update—is slower. Touch screen and color capabilities have been largely unimplemented [10]. Also, the main devices that use electronic ink, e-readers, have limited functions because they are so specialized.

For future electronic ink devices, researchers and engineers are looking to develop thinner, more flexible, and more durable displays. They seek to increase responsiveness, refresh rate, and touch-screen and animation capability of the displays. Another constant area of concern is improving contrast to increase readability in all levels of light [11].

Electronic ink makers are taking several approaches to meet these goals. Some seek to improve upon existing electrophoretic ink technology. Others focus on developing newer types of electronic ink that have demonstrated potential. Like electrophoretic ink, these other inks imitate the appearance of ordinary ink on paper, but through different mechanisms. Electrowetting technology, for example, applies voltage to control the shape of an oil-water interface, which moves quickly allowing for a high refresh rate. Electrofluidic technology uses electricity to control the movement of liquids through tiny cavities, producing vivid colors and highly reflective screens. Cholesteric liquid crystals use stable liquid crystals that reflect light and can be made into thin and flexible sheets [4]. These different types of electronic ink have yet to be released on the market but have great potential for future applications in all kinds of displays and screens (Fig. 5).

Conclusion

Electronic ink is a fascinating technology that bridges the gap between the digital society of brightly lit computer screens and the traditional world of pen and paper. Since its introduction in the early 2000s, electronic ink technology has improved rapidly through advancements in engineering and is still in rapid development. The most recent e-readers have yielded dramatically improved contrast and increased responsiveness compared to their predecessors. In addition, many electronic ink technologies beyond electrophoretic ink are in development and will likely reach the market within the next decade. Regardless of whether you want to conveniently download and read college textbooks or save the planet by conserving trees, look forward to seeing more and more electronic ink options in the future.