Microbial Fuel Cells (MFCs) use bacteria to convert organic waste material into electrical energy. This environmentally-friendly process produces electricity without the combustion of fossil fuels. MFCs have various practical applications such as in breweries, domestic wastewater treatment, desalination plants, hydrogen production, remote sensing, and pollution remediation, and they can be used as a remote power source. Widespread use of MFCs in these areas can take our waste products and transform them into energy.

Introduction

Washing one’s hands with soap is usually accompanied with the satisfaction of killing harmful germs. However, scientists in many research labs around the world seek to put those pesky germs to work generating electricity. Microbial Fuel Cells (MFCs) are an emerging technology that uses bacteria to generate electricity from waste. Bacteria in a Microbial Fuel Cell break down our food and bodily wastes, effectively generating power from the materials that are usually thrown away. By tapping into this previously unharnessed source of power, clean, sustainable energy can be produced at low cost.

MFCs are especially valuable in that there are many applications of their use help to reduce pollution and cut water treatment costs in a sustainable and environmentally-friendly way. Currently, Microbial Fuel Cells are used to produce electricity while simultaneously cleaning wastewater. With future development, MFCs have the potential to produce hydrogen for fuel cells, desalinate sea water, and provide sustainable energy sources for remote areas. The Microbial Fuel Cell, which has historically been used only as a novelty in science fairs, is now a developing reality with great potential for improvements in cleaning techniques and power-generating processes.

What is a microbial fuel cell?

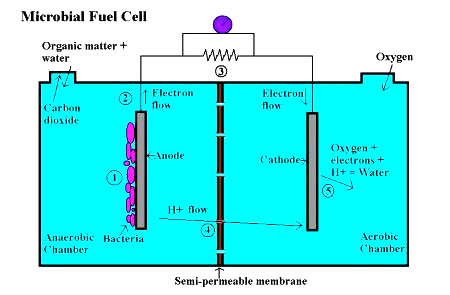

Microbial fuel cells harness the power of bacteria and convert energy released in metabolic reactions into electrical energy. The actual cell consists of two electrodes separated by a semi-permeable membrane submersed in an electrolyte solution.

Fig. 1 depicts a typical MFC set-up in a research laboratory. The electrodes are connected by a wire and the anode (negative electrode) has bacteria growing on it. These bacteria break down food wastes and sewage to generate an electric current. Using microbes to generate electricity implies that the processes in an MFC are self-sustaining; the bacteria replicate and continue to produce power indefinitely as long as there is a food source to nourish the bacteria. Moreover, MFCs are very efficient, do not rely on fossil fuels for energy, and can run effectively on sources like food waste and sewage.

How Does a Microbial Fuel Cell Work?

As shown in Fig. 2, the Microbial Fuel Cell is divided into two halves: aerobic and anaerobic. The aerobic half has a positively charged electrode and is bubbled with oxygen, much like a fish tank. The anaerobic half does not have oxygen, allowing a negatively charged electrode to act as the electron receptor for the bacterial processes. The chambers are separated by a semi-permeable membrane to keep oxygen out of the anaerobic chamber while still allowing hydrogen ions (H+) pass through.

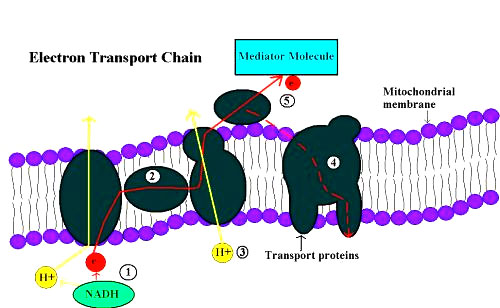

In the anaerobic chamber, a solution containing food for the bacteria is circulated. This food consists of glucose or acetate, compounds commonly found in food waste and sewage. The bacteria metabolize food by first breaking apart the food molecules into hydrogen ions, carbon dioxide, and electrons. As shown in Fig. 3, bacteria use the electrons to produce energy by way of the electron transport chain. The microbial fuel cell disrupts the electron transport chain using a mediator molecule to shuttle electrons to the anode. In many ways, a microbial fuel cell is an extension of the electron transport chain where the final step of the process (the combination of oxygen, electrons, and H+ to form water) is transferred outside of the bacterial cell from which energy can be harvested.

A Brief History of the Microbial Fuel Cell

The idea of obtaining energy from bacteria began in 1911 with M. C. Potter, a professor of botany at the University of Durham [1]. In his studies of how microorganisms degrade organic compounds, he discovered that electrical energy was also produced. Potter had the idea of trying to harvest this newfound source of energy for human use. He was able to construct a primitive microbial fuel cell, but not enough was known about the metabolism of bacteria for the design to be improved upon.

In fact, little development occurred on his primitive designs until the 1980s. M. J. Allen and H. Peter Bennetto from Kings College in London revolutionized the original microbial fuel cell design. Spurred by their desire to provide cheap and reliable power to third world countries, Allen and Bennetto combined advancements in the understanding of the electron transport chain and significant advancements in technology to produce the basic design that is still used in MFCs today. However, use of MFCs in third world countries is still in the pilot stages because of the complexities of simplifying the design enough to allow poor rural farmers to build them. The advancements by the Kings College team have shown the scientific community that the microbial fuel cell can be useful technology and generate increased interest in its development.

As scientists all over the world began researching the microbial fuel cell, one major question still remained: how do the electrons get from the electron transport chain to the anode? While researching this problem in the 1990s, B-H. Kim, a researcher from the Korean Institute of Science and Technology, discovered that certain species of bacteria were electrochemically active and didn’t require the use of a mediator molecule to transport electrons to the electrodes. Thus, a new type of microbial fuel cell was born that eliminated the use of the expensive and sometimes toxic mediators.

Currently, researchers are working to optimize electrode materials, types and combinations of bacteria, and electron transfer in microbial fuel cells. Even though the idea of harnessing the energy produced by bacteria has been around for almost 100 years, researchers have just begun to fully understand the MFC and how to bring out its true potential.

Ways the MFC can improve the world

The microbial fuel cell has current and potential uses in brewery and domestic wastewater treatment, desalination, hydrogen production, remote sensing, pollution remediation, and as a remote power source. Many new applications are beginning to be tested and may come into widespread use in the near future.

Brewery Wastewater Treatment

Brewery and food manufacturing wastewater can be treated by microbial fuel cells because their wastewater is rich in organic compounds that can serve as food for the microorganisms. Breweries are ideal for the implementation of microbial fuel cells, as their wastewater composition is always the same; these constant conditions allow bacteria to adapt and become more efficient. Currently, Fosters, an Australian beer company, has begun testing out an MFC to clean its wastewater while generating electricity and clean water [2]. Fosters has installed the first small-scale microbial fuel cell for brewery wastewater treatment, pictured in Fig. 4. Each long tube is one large Microbial Fuel Cell. Twelve MFCs are placed in parallel to clean the large volume of wastewater. Wastewater flows in at the top, is cleaned by bacteria, and comes out the bottom as purified water. Partnered with the University of Queensland, Fosters’ plans to improve the MFC’s cleaning power and electrical output and eventually build a 660 gallon, 2 Kilowatt MFC that cleans all of the company’s wastewater. The power generated from cleaning the brewery wastewater is expected to pay for the initial cost of the Microbial Fuel Cell in ten years.

Sewage Treatment

Sewage wastewater can also be converted via microbial fuel cells to decompose the waste organic material contained within it. Research has shown that MFCs can reduce the amount of organic material present in sewage wastewater up to 80% [3]. The process is very similar to brewery wastewater treatment, with the difference being that the water must first be pretreated to remove toxins and other non-biodegradable materials. This is a challenging step because sewage wastewater often varies in composition and may require extensive treatment before it can be cleaned by the MFC. However, this extensive treatment is justified by the electricity produced while cleaning the wastewater. The electricity production from MFCs will help to offset the high costs of processing wastewater [4]. Wastewater treatment plants could end up dumping fewer pollutants into oceans and rivers if the money saved from the electricity bill is put to work further cleansing the wastewater.

Desalination

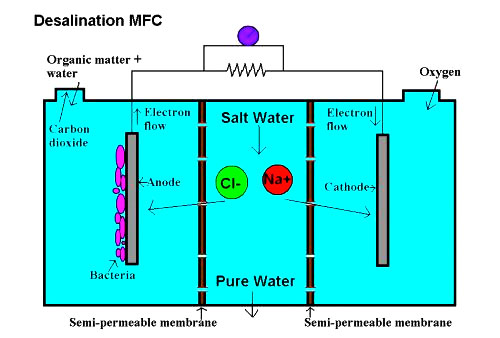

Desalination of sea water and brackish water for use as drinking water has always presented significant problems because of the amount of energy required to remove the dissolved salts from the water. By using an adapted microbial fuel cell, this process could proceed with no external electrical energy input [5]. By adding a third chamber in between the two electrodes of a standard MFC and filling it with sea water, the cell’s positive and negative electrodes attract the positive and negative salt ions in the water and, using semi-permeable membranes, filters out the salt from the sea water, as seen in Fig. 5. Salt removal efficiencies of up to 90% have been recorded in laboratory work, but much higher removal efficiencies are required to produce drinking-quality water [5].

Microbial fuel cells can be used to generate hydrogen for use as an alternative fuel. When used for hydrogen production, the MFC needs to be supplemented by an external power source to get over the energy barrier of turning all of the organic material into carbon dioxide and hydrogen gas [2]. The standard MFC is converted to hydrogen production by keeping both chambers anaerobic and supplementing the MFC with 0.25 volts of electricity [6]. Hydrogen bubbles form at the cathode and are collected for use as fuel source [7]. Although electricity is used instead of generated as in normal MFCs, this method of producing hydrogen is very efficient because more than 90% of the protons and electrons generated by the bacteria at the anode are turned into hydrogen gas [8]. Conventional production of hydrogen requires 10 times the amount of energy as an adapted MFC, making the MFC the most efficient and environmentally-friendly way to generate hydrogen for use as a fuel.

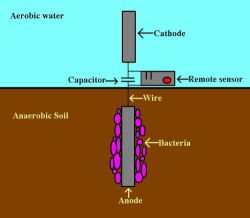

MFCs can run low-power sensors that collect data from remote areas. For example, scientists have replaced a traditional wireless thermometer in the Palouse River in Washington with one powered by a MFC. This microbial fuel cell is integrated into the riverbed, as shown in Fig. 6. A simple microbial fuel cell consisting of a cathode attached to an anode by a metal wire. By placing the anode in the anaerobic sediment of a river or ocean and placing the cathode in the aerobic water right above the sediment, a current is generated. Anaerobic bacteria that naturally grow in the sediment produce the small current that can be used to charge a capacitor to store energy for whenever the sensor needs it. One major advantage of using a microbial fuel cell in remote sensing rather than a traditional battery is that the bacteria reproduce, giving the MFC a significantly longer lifetime than traditional batteries [2]. The sensor can thus be left alone in a remote area for many years without maintenance.

Cleansing Polluted Lakes and Rivers

Microbial fuel cells can also be used in the bioremediation of water containing organic pollutants such as toluene and benzene, compounds found in gasoline. The MFC design is altered so that the fuel cell floats on top of polluted water. The anode is submerged in the water where organic pollutants feed the bacteria while the cathode floats on top of the water. The organic pollutants are decomposed to carbon dioxide and water, cleansing the polluted lake or stream. The MFC can be left alone in remote natural bodies of water, just like the remote sensor [9]. A working prototype shown in Fig. 7 has been deployed in a polluted marsh in Mexico and is beginning the process of cleaning up the worlds remote rivers.

Remote Power Source

The advancement of microbial fuel cell technologies in the 1980s was largely spurred by the dream of providing cheap, accessible power to remote regions of Africa, where 74% of the population lives without electricity [10]. Although implementation of homemade MFC use in Africa is just beginning, microbial fuel cells that run on manure and dirt have been developed and tested. The electrical current produced by a simple homemade MFC is enough to recharge a cell phone battery, an important communication and lighting tool to rural African communities. Companies such as Lebone Solutions are trying to create simple microbial fuel cells that can be easily built by using commonly found items in rural farming communities. The materials required to construct this simple MFC are soil, manure, copper wire, buckets, and graphite cloth. Fig. 8 shows the simple homemade MFC that could charge cell phones in poor African countries.

Microbial fuel cells have become an interesting and promising area of research. The many applications of MFCs will help to reduce the use of fossil fuels and allow for energy gain from wastes. MFC technology does not have the power to change the world single-handedly; microbial fuel cells will never be able to produce enough electricity to take the place of a coal-fired power plant. They will, however, help to bring the world to becoming a sustainable and more environmentally-friendly place.