Maglev trains have the potential to revolutionize how we travel. The trains levitate using magnets, zipping through the air at speeds above 350 mph. These high speeds would allow for maglev trains to be a realistic alternative to flying, and they use very little energy and emit no pollutants during transportation. They require little maintenance, and can help to reduce growing road and air congestion. From their history, technology, and costs to the future potential, maglevs are nothing short of an engineering feat.

“Where’s my Flying Car?”

“Where is my flying car?” has become an idiomatic expression often used to decry one’s frustration with the lack of advancement of modern technology. With more and more technologies that had only existed in the realm of science fiction crossing into reality, it seems puzzling that one of its main staples, the flying car, has not made the leap yet. Mankind is making progress; while flying cars may not exist in the original sense of the term yet, flying, or, rather, floating trains are already in existence. Several countries and private corporations have already begun researching and implementing the use of magnets to power high-speed trains, commonly referred to as maglev (short for magnetic levitation) trains.

Maglev trains have potential to revolutionize how we travel. The trains themselves are less costly and noisy than conventional trains and they require less maintenance due to their levitation eliminating most of the friction. Maglev trains use far less energy than conventional trains and emit no pollutants. High speeds allow for maglev trains to be a realistic alternative to flying, and they can help reduce air and road congestion as more people are moving around the world. Despite these benefits, creating a large-scale maglev system is a daunting task. The infrastructure for the trains does not currently exist, and must all be built. The track contains almost all the components needed for the trains to work, and generalized cost projections put the price of maglev tracks at around $10 million per mile. Once the infrastructure is built, however, maglev trains become inexpensive to operate due to their simplicity and lack of required maintenance. While the initial startup expenses are high, these trains have the potentional to make travel faster, more efficient, and more environmentally friendly [1] [2]. Although maglev trains do have some setbacks and challenges to overcome before their widespread adoption, the technology has proven itself a worthy successor to high speed rail through projects of both small and large scales.

History

Though one might assume that the maglev is a brand new technology because they have only become widely adopted in recent years, its origins actually date back to the mid-19th century. The first mention of related technologies appears in a rough description of the maglev concept given by Charles Wheatstone of King’s College in the 1840’s [3].

The first demonstration of a maglev train on a test track was completed by German company Transrapid International in 1971. Japan was not far behind, holding a demonstration of their first levitating train in 1972. By 1977 Japan was able to propel a maglev train at over 320 mph. This top speed continued to improve through the 1980s and 90s, with Japanese maglev reaching a world-record 361 mph in 2003. Throughout the 80s and 90s, general excitement about maglev trains reached a high point. Many different potential routes were mapped out crossing Europe, Asia, and the United States without a true understanding of the costs required for building these routes.

China, typically a leading country in the development of alternative energy and technology, had long been interested in developing maglev as well, but lacked the economic means to do so. Taking advantage of their booming economy, they started designing and testing maglev technology in 1999. By 2001 they had begun construction on a 20 mile maglev route linking Shanghai to nearby Pudong International Airport. The train embarked on its maiden voyage in 2002, and reached a top operating speed of 293 mph in 2003. In 2004 the train became the first publicly accessible maglev train offering regular commercial service, and it continues to carry commuters today.

The 2000s have generally seen a worldwide lack of enthusiasm for maglev trains. Germany, Japan, and China remain invested in spurring maglev growth, but most other countries are unsure of the new technology. The unfortunate current reality of maglev is that despite its futuristic appeal, efficiency and speed, the cost of building the infrastructure required for maglev operation is often too great when conventional train travel is a much cheaper option. As the technology improves and becomes less costly, driven by a need for increased fuel efficiency, environmentally sustainable travel, and skyrocketing road and air congestion, maglev may eventually become a more compelling alternative to traditional means of travel [4].

Magnetic Levitation: EDS and EMS

The first related patent was issued in the US under the title “electric traction apparatus” to Alfred Zehden in 1905 [5]. Zehden’s patent describes the basis of what is now known as a linear induction motor: a propulsion device that produces motion by using magnets to create an attractive force between a track and a body instead of using a rotating shaft to produce torque, as is the case in conventional motors. This is one of the core technologies used for maglev, as it allows a contact-less method of propulsion for a car on a track. This patent came amid a heightened interest in electricity resulting from the widespread adoption of the light bulb and electric motor; it was, however, most likely treated as a mere novelty due to its lack of a practical application. It wasn’t until Eric Laithwaite, an undergraduate at Manchester University, took interest in the subject in the 1948 that a full scale model was built [6].

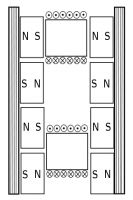

The basic physics of a linear motor is easy to demonstrate: using two magnets, put them close together on a smooth surface and turn them so that they repel each other; hold one of the magnets so that it can’t move and the other will slide away [7]. Repeat this simple process and the effect can be used to propel a body forward. The basic layout of a linear motor is shown in Fig. 1; a body containing magnets is placed upon a “track” of electromagnets with alternating polarity. Assume that the body is in the state depicted by the top of the figure when the electromagnet is turned on. The current in the electromagnet is then reversed, reversing the polarity of the electromagnet. This causes the magnets in the track to repel the magnets in the body, propelling it forward, as shown in the state at the bottom. The magnet then realigns itself, returning to the first state a bit down the track from its beginning state. The cycle is then repeated, with the current and polarity of the electromagnet reversed so that the body is propelled further forward.

When the tracks are on both sides of the vehicle and when the alternation of the current is conducted at the right frequency, the body is continuously propelled forward. The result is a system that can move a body forward without the need for any physical contact. This is called a linear induction motor, because the system works as if a regular motor was “unrolled” onto a linear track, with the rotor placed in the body and the stators, or stationary magnets, unraveled onto the track.

EDS: Electrodynamic Suspension

Laithwaite, now known as the father of maglev, continued his research on the linear induction motor after becoming a professor at Imperial College of London in 1964 [6]. He worked to increase their efficiency and strength, and thus their practicality in real world applications. The next big step in the field of maglev came with Laithwaite’s development of the magnetic river in 1974: an electrodynamic suspension (EDS) magnetic levitation system, or in other words, a magnetic system that works to keep a body afloat above a track [8].

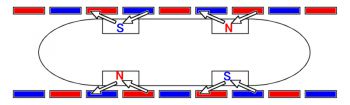

One interpretation of this is to have another set of electromagnets in the track (Fig. 2). In this configuration, the electromagnets in the tracks serve two purposes. The first is to act as a linear motor. The second is to repel the train from the ground and walls, ensuring that it is stably suspended above the tracks [9]. This is achieved by taking advantage of Lenz’s and Faraday’s laws: a changing magnetic field, as occurs when the magnets in the body are passing by, generates an electromotive force in the electromagnetic circuit in the tracks. While the mathematical proof for this system is beyond the scope of this article, simply put this means that if the train passes by the electromagnets in the track quickly enough, the resulting change in magnetic field will induce a current within the electromagnets. This in turn causes the track to produce a repelling magnetic force, represented by the arrows, which are used both to levitate the train and to keep it within the width of the track. When implemented successfully, this system makes the train “fly,” lifting it up to a few inches above the ground [8].

The advantages of EDS are that the levitation system itself does not require power, and can be integrated with the Linear motor. EDS does, however require the train to have wheels in order to accelerate to the “take off” speed required for the levitation force to become strong enough to lift the train. EDS also means that a strong magnetic field is created on-board, which can pose a threat to pace-makers and other artificial organs. There is currently no work-around for this, so trains relying on this system remain inaccessible to those with artificial hearts. An advanced form of this EDS is used in the Japanese Shinkansen Maglev (Fig. 3) currently under construction, but as of yet it remains unused in any commercial system.

EDS: Inductract

Another experimental design being pursued primarily by the United States is known as Inductrack, which is a type of EDS that uses permanent room-temperature magnets instead of supercooled electromagnets to produce magnetic fields. This design uses a small power source to accelerate the train on rolling auxillary wheels in the same manner as Japanese EDS trains. Once it reaches a few mph speed it begins to levitate at around 3 cm, pushed up by induced magnetic fields in the bottom of the guideway. Unlike EDS trains, the permanent Inductrack magnets also induce currents in the sides of the guideway which produce magnetic fields that propel the train without the need for an external power source. This design is extremely energy efficient, only requiring small amounts of external power for the starting and stopping phases of travel. The magnets on the train require no external power to run. However, this design is also the most difficult to implement due to the need for very robust permanent magnets. This design is still in its youthful stages, though a test track has been set up by the General Dynamics Corporation which levitates and propels a small test train at around 25 mph [7].

EMS: Electromagnetic Suspension

Meanwhile, an alternative technology to EDS was developed for Maglevs that didn’t require such strong magnetic fields. Called electromagnetic suspension (EMS), it is based on the simple idea of using active magnets in the track to support the train, as opposed to EDS where inactive magnets are induced into creating a repelling force. EMS systems commonly use permanent magnets, which don’t require power, to levitate the body. The problem with this is that placing a repelling magnet atop another magnet does not cause the top magnet to simply float above the bottom magnet; the system is unstable, meaning the top magnet will be pushed to the side, in this case causing the train to derail. To address this problem, modern EMS systems supplement the permanent magnets with computer-operated electro-magnets to keep the train in place. This system has the advantage of being able to levitate the body at lower speeds, and with smaller magnetic fields than EDS; however they require closer monitoring and constant adjustments of the electromagnets to maintain stability [10]. This system has been used in all commercial maglev systems so far, including the German Transrapid system built by Siemens and ThyssenKrupp, recently used for the Shanghai maglev train shown in Fig. 4 [10].

Maglev: A Promising Technology

Together, the linear propulsion motor and magnetic levitation system provide a frictionless alternative to the traditional train. Thanks to linear induction, there are no moving parts in the propulsion system, and the magnetic suspension means that maglev trains do not touch the ground. This means that the only drag experienced is aerodynamic and electromagnetic, allowing Maglevs to reach top speeds of over 360 mph with a lower energy consumption than their wheeled predecessors. A beneficial side effect of this is that the trains are quiet and stable, since the only noise and disturbances they generate come from the displacement of air.

The lack of moving parts also means that these trains need less maintenance. Since they are not in contact with the rails, there in no wear on the trains or rails. Maintenance is minimal, and the vehicles follow a maintenance schedule closer to that of aircraft than that of traditional trains, meaning that their maintenance schedules are based on hours of operation rather than distance traveled [11]. Maglevs are also immune to weather since their tracks are not subject to heat deformation or freezing, reducing traditional constraints placed on rail travel. This makes the technology ideal for any location with extreme weather.

Lastly and most importantly, linear motors allow maglevs to accelerate and decelerate to and from high speeds in a short distance. This makes them ideal both for rapid inner-city travel since this means that they can accelerate to their top speeds even when stations are close together. At average speeds of 360 mph, they are not quite as fast as the average jet plane that cruise at around 500 mph. However, maglevs can be a competitive alternative along mid-range routes because train travel does not require the security and preparation necessary to travel through an airport, reducing travel time. For routes of up to 500 miles, taking a maglev could easily become cheaper, quicker, and safer than traveling by air.

The Limitations

Despite all of these advantages of Maglevs over conventional rail, there are still many challenges that must be overcome in order to win the battle for prominence on the rails. The first is perception of safety. In the decades of testing that maglevs have gone through so far, they have encountered only a handful of accidents, which is not a bad track record. Many in the public remain wary of the technology, however, since it has had limited use in commercial operation and has yet to prove itself free of negative health effects or other threats to the public’s well being. Just recently, a project intended to extend the Shanghai maglev was shelved, partly due to concerns by the track’s neighbors over potential health problems arising from the magnetic fields [12]. Since the Shanghai maglev uses EMS, which has weaker magnetic fields than the EDS, this is likely to be an even greater issue for EDS-based technologies.

The maglev’s other weakness, and the main reason why the Shanghai maglev extension failed, is cost. Building a track of around 50 miles can cost billions of dollars, several times more than any conventional rail technology. While in a few areas, particularly those with high ridership, Maglevs do make sense, for the majority of cases they remain impractical. To date, the only maglev systems built have been used either as experimental tracks, for airport transportation, or for exhibition purposes.

Flying into the Future

An exciting future possibility for maglev trains is known as evacuated tube transport. This involves the trains traveling in enclosed vacuum tubes with very little air resistance. Implementing this involves permanently removing air along the travel route; the passengers ride in air-locked train cars. Having essentially no air present in the tunnels means that there is no air friction limiting the speed of the trains, leaving them free to reach projected top speeds as high as 4,000 to 5,000 mph. To put it in perspective, this is roughly twice as fast as the fastest manned aircraft, the SR-71 Blackbird [13] [14].

These extremely high-speed trains have great potential for intercontinental travel, allowing for passengers to cross over huge spans of land in very short time frames. As an example, traveling from New York to Los Angeles would only take roughly 30 minutes. An additional future direction of these vacuum-tube trains involves oceanic travel. Preliminary research and modelling of a trans-Atlantic underwater vacuum tunnel have shown the feasibility of these types of projects. The tunnel would be constructed by submerging sections of neutrally buoyant material 150 – 300 ft below the surface of the water. The tunnel would allow for passengers to cross the Atlantic from New York to London in roughly 1 hour. From an engineering standpoint, this project is feasible to build even today. However, like most aspects of maglev travel, cost is the major hindrance. Initial projections put the cost of a trans-Atlantic tunnel between $88 and $175 billion dollars [15].

There are numerous other proposals for both short and long distance Maglevs around the world, but few seem likely to begin construction in the near future primarliy due to economic concerns. It appears that the long-term success of Maglevs will depend on the success of the pioneering projects being implemented now, as well as the ability of companies to lower the cost of the technology.

Conclusion

Maglev is a technology that has been around for some time, but has only recently become feasible after years of development. Even now, its practicality is questionable due to its high costs. As shown in recent implementations and upcoming projects, however, maglev shows great potential and is continuously improving thanks to correspondingly improving technologies. With any luck, maglevs will soon become a much faster and more reliable alternative to conventional rail; and once mankind is able to figure out the secret to flying trains, we can only assume that the flying cars cannot be too far behind.